The GCJ connected to the intermediate shaft drum gear coupling is a sophisticated mechanic...

Products

Products

Don't hesitate to send a message

+86 511 8572 3900

+86 15106109009 Keep in touch

Products

Our main products are toothed coupling, elastic sleeve column pin coupling, elastic column pin coupling, gear coupling with elastic pin, a universal coupling, tire coupling, jaw coupling, star coupling, diaphragm coupling, drum coupling and grid coupling, the Oldham coupling, flange coupling, clip shell coupling, GL type roller chain coupling and a safety coupling, and so on.

-

-

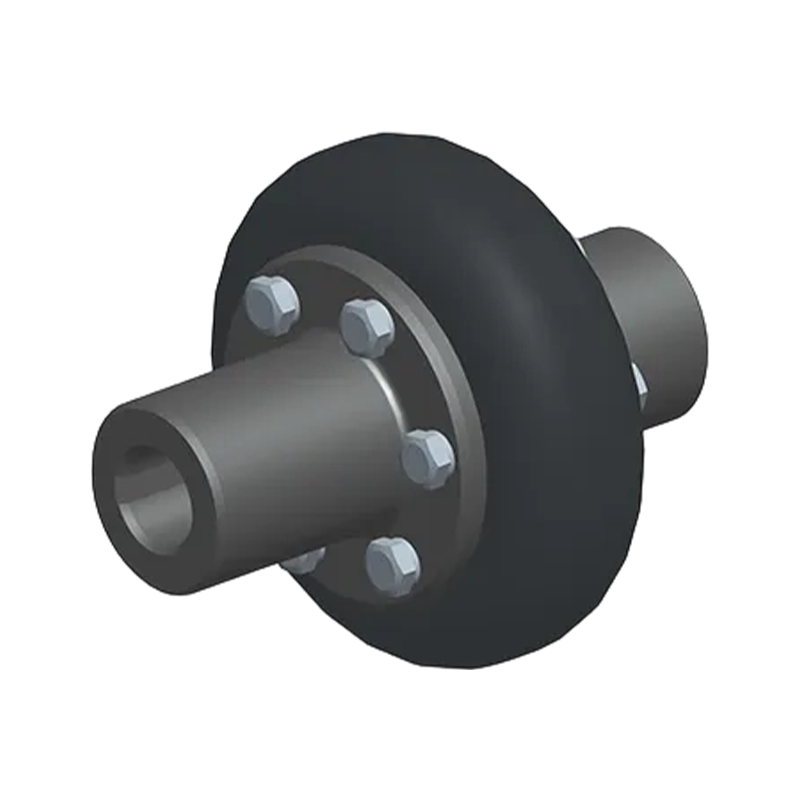

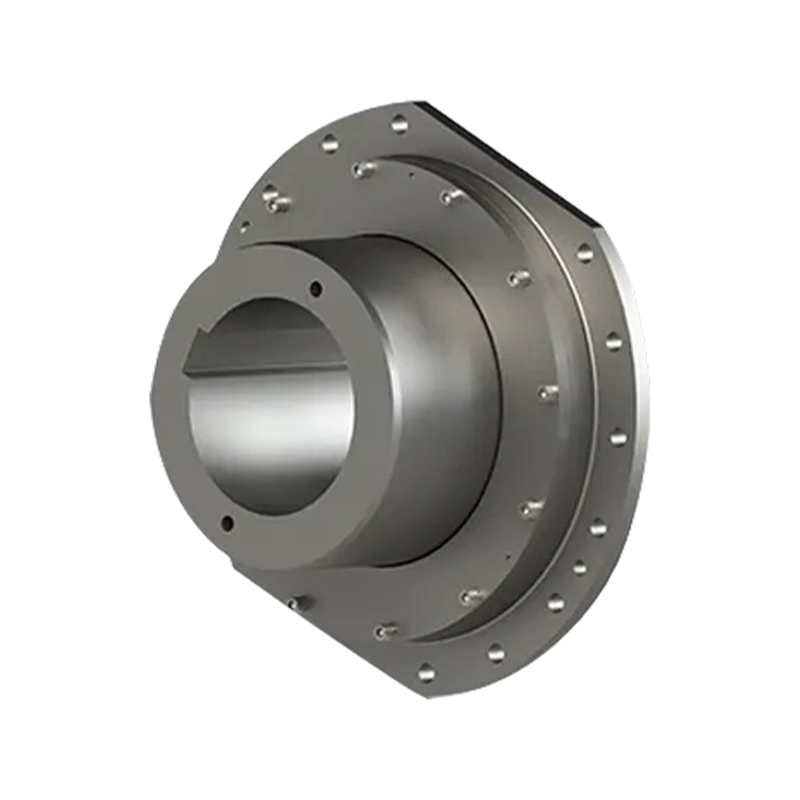

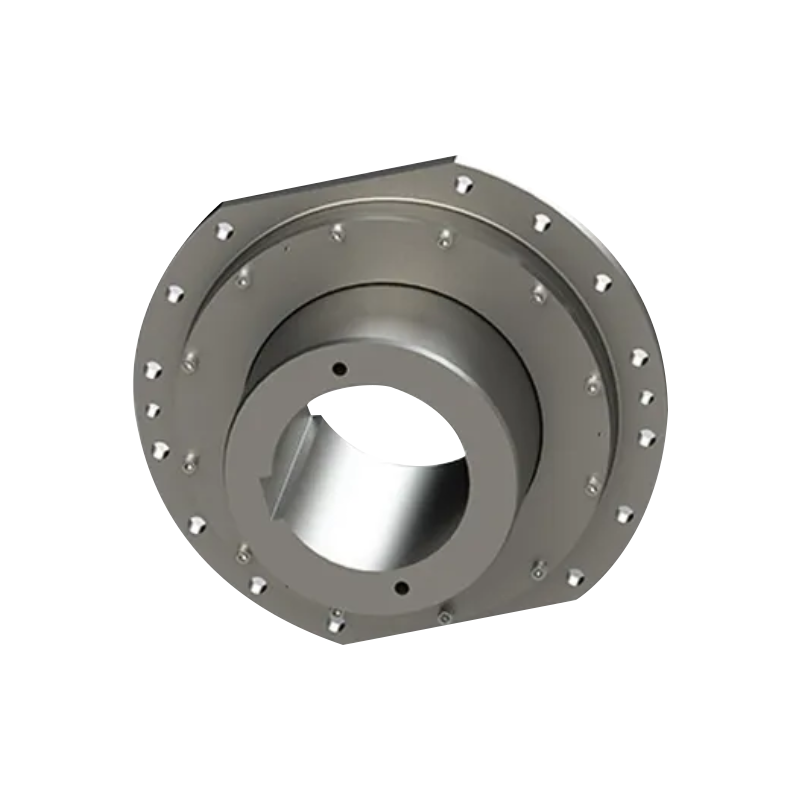

GSC Through type drum gear coupling(Q/YG14019X-2018)

GSC Through type drum gear coupling(Q/YG14019X-2018)The GSC Through Type Drum Gear Coupling represents a pinnacle of engineering excellence in...

-

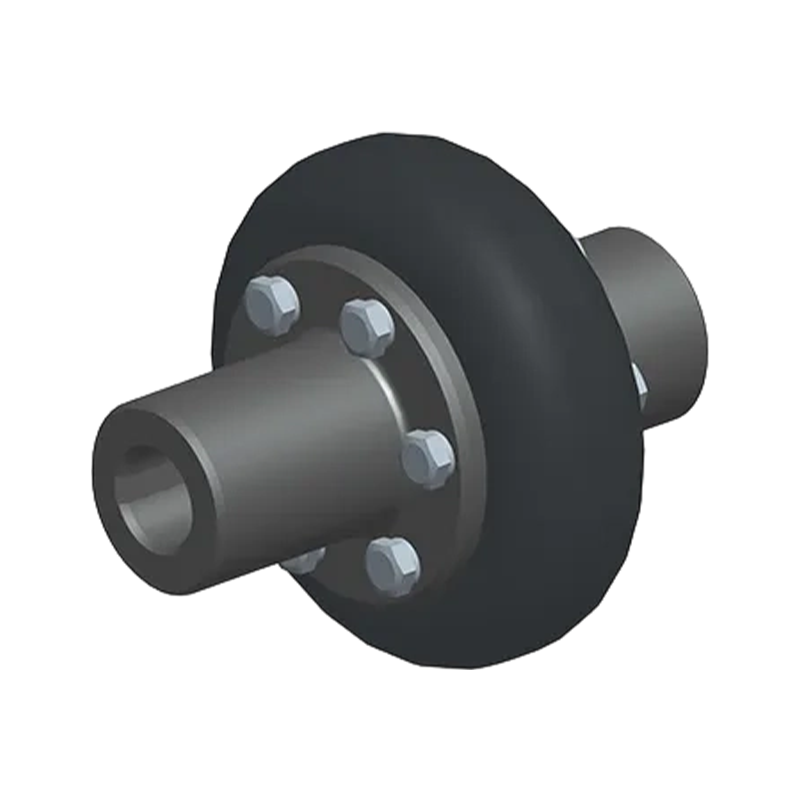

Heavy-duty axial drum gear coupling

Heavy-duty axial drum gear couplingThe heavy-duty axial drum gear coupling is designed for mechanical transmission systems th...

-

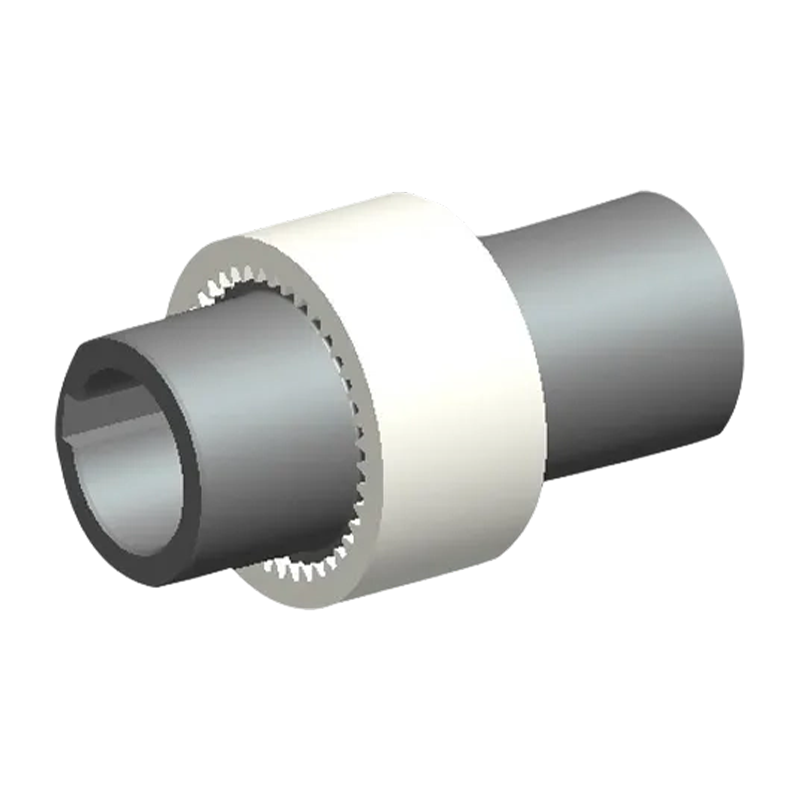

NC Nylon inner gear ring drum gear coupling(Q/YG14021X-2018)

NC Nylon inner gear ring drum gear coupling(Q/YG14021X-2018)The NC Nylon Inner Gear Ring Drum Gear Coupling represents a cutting-edge solution in mech...

-

QJC type drum coupling (Q/YJ16027X-2018)

QJC type drum coupling (Q/YJ16027X-2018)The QJC Type Drum Coupling is a highly reliable and efficient mechanical component designe...

-

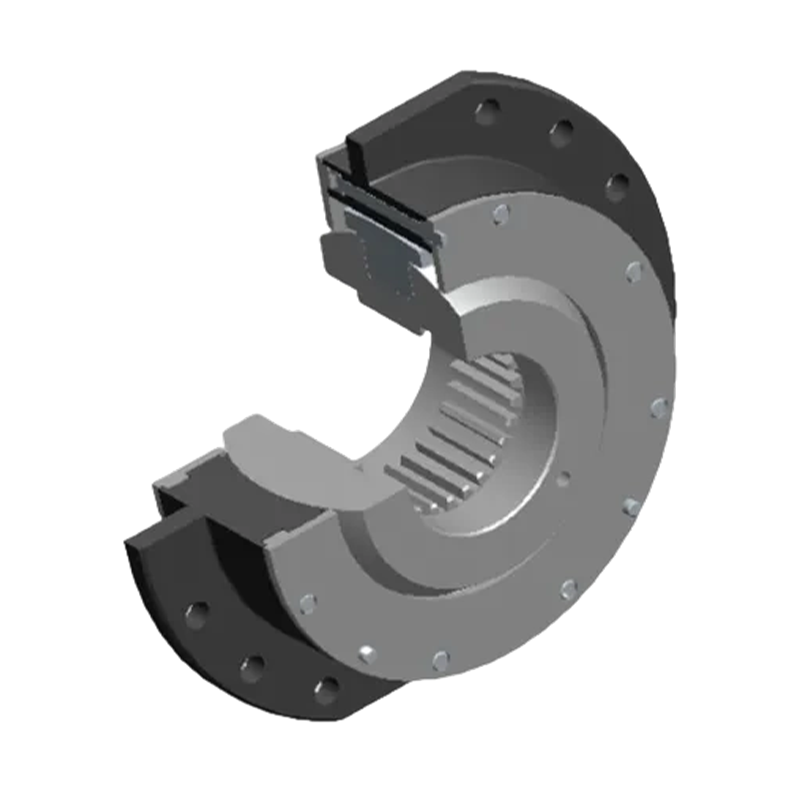

GJC drum coupling(Q/YJ 16028X-2018)

GJC drum coupling(Q/YJ 16028X-2018)The GJC type drum coupling is a high-performance transmission component specially designed...

-

QGC type involute spline coupling spherical roller coupling(Q/YJ16029X-2018)

QGC type involute spline coupling spherical roller coupling(Q/YJ16029X-2018)The QGC drum coupling is a spherical roller heavy-duty transmission component. Its core de...

-

QGCA type cylindrical shaft hole coupling spherical roller coupling (Q/YJ 16030X-2018)

QGCA type cylindrical shaft hole coupling spherical roller coupling (Q/YJ 16030X-2018)The QGCA drum coupling is a spherical roller heavy-duty transmission component. Its core d...

-

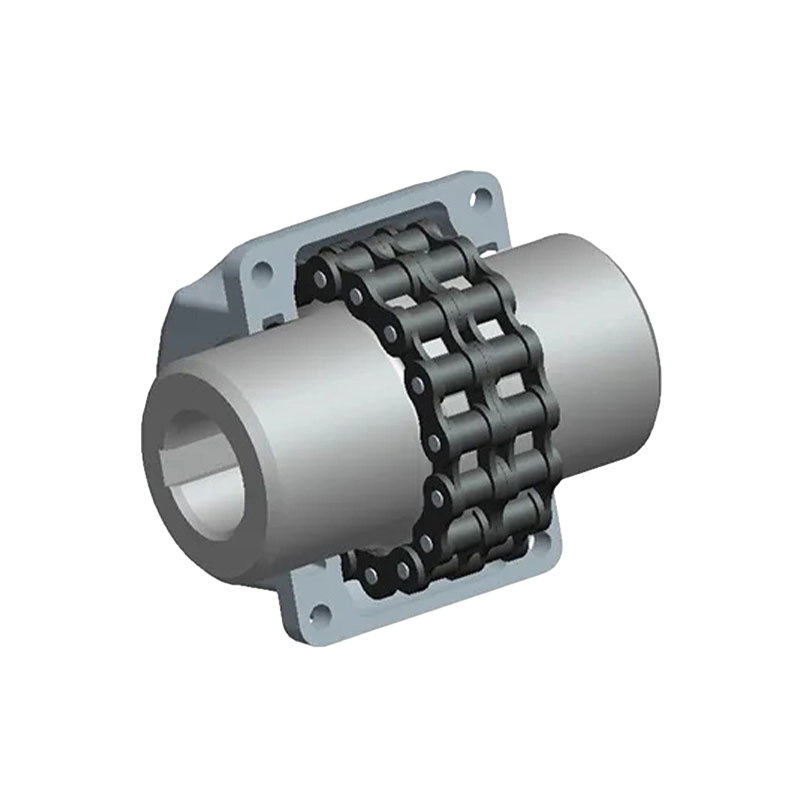

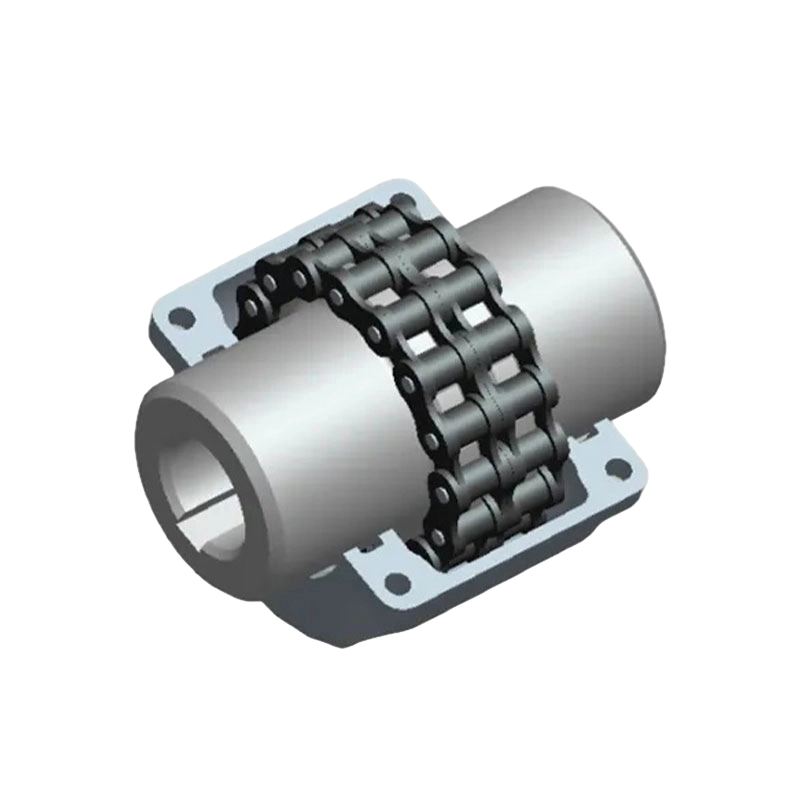

LC roller chain coupling(Q/YL 17031X-2018)

LC roller chain coupling(Q/YL 17031X-2018)Structural features: The working principle is to use a double-row chain and two parallel s...

-

KC type roller chain coupling(Q/YL 17032X-2018)

KC type roller chain coupling(Q/YL 17032X-2018)Introduction: The KC roller chain coupling is a versatile and reliable mechanical coupling...

-

HJ type cross slider coupling(Q/YH 18033X-2018)

HJ type cross slider coupling(Q/YH 18033X-2018)Introduction: The HJ type cross slide coupling is a precision-engineered mechanical coupli...

-

HN type slider coupling

HN type slider couplingIntroduction: The HN type slider coupling is a precision-engineered mechanical coupling sy...

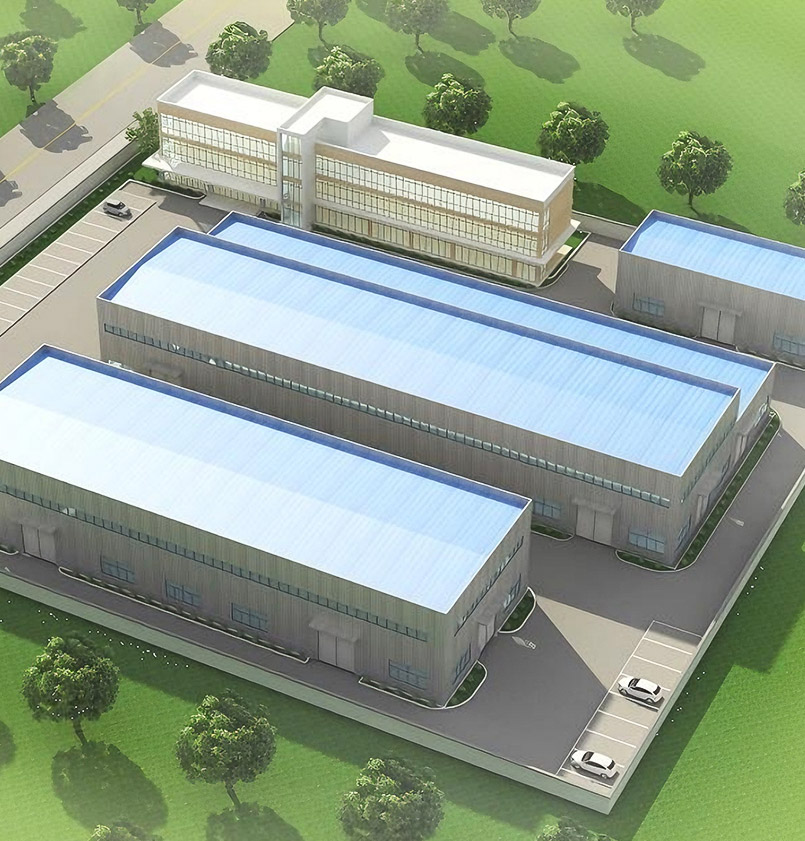

Zhongye Heavy Industry Technology (Zhenjiang) Co., Ltd. is located in a well-known ancient city, Zhenjiang. We are an enterprise integrating R & D, manufacturing, and sales. Our products are widely used in metallurgical equipment, mining equipment, water equipment, lifting equipment, paper equipment, port equipment and other industries.

Our main products are toothed coupling, elastic sleeve column pin coupling, elastic column pin coupling, gear coupling with elastic pin, a universal coupling, tire coupling, jaw coupling, star coupling, diaphragm coupling, drum coupling and grid coupling, the Oldham coupling, flange coupling, clip shell coupling, GL type roller chain coupling and a safety coupling, and so on. Our company also undertakes a variety of non - standard coupling designs and manufacturing.

New workshop covers an area of about 16463.52 m². heavy workshop 5,500 M2, Precision workshop 4,600 m² , office building and the gymnasium 2000 M2, Dinning hall 500m² , Warehouse 1000 m², Roads, greening, parking areas 3563 M2.

-

2025.08.08The differences between drum couplings and other types of couplingsThe price of coupling is influenced by various factors, including model, specification, material, production process, and supplier, etc. Different drum couplings may have significant price differences. Drum couplings usually have the characteristics of simple structure and convenient maintenance. To determine which is cheaper between drum couplings and universal couplings, a comprehensive comparison based on specific application scenarios, model specifications, and supplier quotations is required. It is recommended to consider the performance, reliability, and applicability of the coupling when choosing it, while also taking cost factors into account comprehensively. Drum couplings have a large load-bearing capacity and can withstand large radial loads, effectively transmitting torque and meeting the needs of various mechanical equipment. In the case of overload, the drum coupling can also maintain a certain degree of elasticity and toughness, preventing damage to the mechanical system, enhancing the reliability and service life of the equipment. It has excellent alignment performance, capable of adapting to minor deviations between the two shafts, ensuring the coaxiality and parallelism of the mechanical system, and reducing vibration and noise. The structural design of the drum coupling is reasonable, and the installation and adjustment process is simple and quick, reducing maintenance costs and workload. The drum coupling has the capabilities of oil-proofing, moisture-proofing, aging resistance and radiation protection. It can be applied in various scenarios and is easy to install and maintain. At the same time, it can adjust the inherent frequency of the shaft system, reduce the amplitude of torsional vibration, thereby buffering and protecting the components of the transmission device, improving the alignment performance, and enhancing the stability of the output power.

-

2025.08.01Elaborate on the installation steps of the diaphragm couplingSeveral groups of diaphragms (thin stainless steel plates) are interlocked with the two halves of the coupling by bolts. Each group of diaphragms is composed of several layers stacked together. The diaphragms are divided into rod-type and different-shaped whole-piece types. The diaphragm coupling compensates for the relative displacement of the two shafts it is connected to through the elastic deformation of the diaphragms. It is a high-performance metal strong element flexible coupling, which does not require lubrication. It has a compact structure, high strength, long service life, no rotational clearance, is not affected by temperature and oil contamination, and has the characteristics of acid and alkali resistance and corrosion resistance. It is suitable for shaft system transmission in high-temperature, high-speed, and corrosive medium working environments. Installation steps for the diaphragm coupling: 1. When installing the coupling at the site, please carefully count all the components to ensure there are no missing parts. One set of the coupling includes one active half coupling, one passive half coupling, one set of six-segment diaphragm assembly, high-strength bolted screws, nuts, and spring washers, totaling six pieces. Before the active and passive halves have been installed onto the corresponding main shaft and aligned properly, please properly store the diaphragm assembly (do not throw, bump, press hard, or hit it) to avoid affecting the accuracy and integrity of the diaphragm. 2. Thoroughly clean the oil stains and paint from the inner hole of the semi-shaft coupling and the outer circle of the flange. Apply oil bath heating or induction heating to the main and passive semi-shafts (the temperature should not exceed 300°C, and it is generally advisable to control it within 160°C to 250°C). Before heating, complete all assembly preparations, check for any dimensional errors in the shaft hole size, length, keyway width, and keyway depth, and whether the main shaft head has severe scratches or dents, to prevent the semi-shafts after heating from not fitting properly during assembly, thereby affecting usage or even causing damage, or due to improper positioning of the product, making it impossible for users to accurately locate during subsequent spare parts installation, thus affecting usage. 3. The primary and secondary semi-flexible couplings installed on the mainframe will undergo alignment installation through the steps of initial alignment, rough alignment and precise alignment. (1.) Initial alignment: This process involves using the naked eye as the control method to position the motor and fan in terms of their horizontal orientation, front-back distance, height difference, and axial angle, etc., in order to prepare for the subsequent alignment. (2.) Rough Alignment: This involves using the simplest methods, such as a ruler or a vernier caliper, as well as a caliper, to ensure that the major planes of the two half coupling devices are parallel to each other, and that the relative spacing conforms to the technical requirement of the gap value t. Generally, the actual value of the gap should be between 0.5mm and 0.8mm greater than the theoretical value. Also, the radial deviations of the upper and lower, as well as the front and rear positions of the outer circles of the flanges of the two half coupling devices should be consistent. Note: Before use, please strictly follow this installation manual and carefully complete the following items. You will obtain a set of elastic coupling that is maintenance-free, long-lasting, low in failure rate, and highly reliable. After-sales Service Commitment: 1. Service Philosophy: Fast, decisive, accurate, considerate, thorough 2. Service Goal: Service quality to win user satisfaction 3. Service Efficiency: If the equipment malfunctions during the warranty period or after the warranty period, the supplier will have maintenance personnel arrive at the site within 24 hours and start the repair. 4. Service Principles: The product warranty period is twelve months. During the warranty period, the supplier will repair and replace the components damaged due to quality issues free of charge. After the warranty period, the cost of the spare parts for component damage will be charged only for the cost, and for equipment damage caused by human factors, the repair or spare parts provided by the supplier will be calculated at cost price.

-

2025.07.18The two shafts of the coupling have a relative offset.The structure of the protective device for the coupling is cylindrical and divided along the axial direction. At both ends, the protective device is connected to the corresponding equipment in the machine by flanges. One end of the protective device should have a telescopic joint, and an O-ring is installed at the telescopic joint. The main functions of the coupling and the clutch are to connect the shafts and transmit motion and torque, and they can also be used as stabilizing devices and for overload protection. When the two shafts have a relative offset, the elastic element undergoes corresponding elastic deformation, playing an automatic compensation role. The coupling can compensate for the offset of the connecting parts due to alignment, and transmit motion or torque when there is a large angle between the two shafts. The elastic body is usually composed of engineering plastics or rubber, and the lifespan of the coupling is the lifespan of the elasticity, as the elastic body is under compression and is not prone to tension. Applying predictable low additional negative forces to the connected devices, compared with similar flexible transmission components, the coupling exerts predictable small forces and torques on the connected devices. It can be disassembled and assembled without interfering with the driving and driven devices, thereby improving equipment utilization. The transmission speed and accuracy are good. It is mainly used in working environments with high and low temperatures, as well as corrosive media containing oil and water. The coupling is mainly composed of two belts with protruding teeth that are closely meshed through an intermediate gasket, and it withstands radial pressure to transmit torque. The coupling generally cannot be disengaged during machine operation and can only be disconnected after the machine has stopped. The clutch can be engaged or disengaged at any time during machine operation. It is widely used in environments with strong vibrations. The performance of the elastic body's temperature determines the operating temperature of the coupling.

-

2025.07.18Elastic couplings are used in a variety of different working environmentsThe elastic coupling transmits torque through elastic elements, resulting in relatively low energy loss during the transmission process, thereby improving the transmission efficiency. The elastic coupling is suitable for various different working environments and conditions, and can meet the requirements of various mechanical transmission systems. The elastic coupling can absorb these vibrations, protecting the generator and other key components, and enhancing the stability of wind power equipment usage. The elastic coupling is suitable for various different working environments and conditions, and can meet the requirements of various mechanical transmission systems. The elastic coupling can absorb these vibrations, protecting the generator and other key components. In construction machinery such as excavators and loaders, the elastic coupling can effectively reduce the impact in the transmission system, lower the equipment failure rate, and improve work efficiency. The forging process enhances the density and mechanical properties of the material. It is important to control the forging temperature and forging force. Heat treatment processes such as normalizing, annealing, and quenching and tempering should be carried out, and the heat treatment temperature and time should be controlled. Turning processing includes rough turning, semi-finish turning, and finish turning, gradually improving the accuracy and surface quality of the parts. The cutting speed and feed rate should be controlled carefully to avoid generating large thermal stress and deformation. Due to errors during manufacturing, installation, and use, there may be a certain degree of deviation between the transmission shafts. Elastic couplings can compensate for these deviations within a certain range, ensuring the smooth operation of the transmission. The elastic couplings can effectively reduce the impact and vibration in the transmission system, improving driving comfort. At the same time, they can also compensate for the shaft deviations caused by manufacturing and installation errors.

-

2025.07.11The coupling can adapt to different working environmentsThe bearing capacity of the coupling and the allowable offset or swing angle are directly related to the curvature radius of the teeth. From the perspective of enhancing the bearing capacity, the larger the curvature radius, the better. When the actual load of the coupling exceeds the pre-defined load, the safety mechanism changes, cutting off the transmission of motion and power, thereby protecting the remaining parts of the machine from damage and providing safety protection. During processing, the cutting tool naturally follows the arc path, so the size of the cutting arc radius determines the size of the curvature radius of the teeth. In addition to providing overload protection, it also has the effect of converting the loaded start-up of the machine motor to an approximately unloaded start-up. When the working load of the shaft system transmission experiences shock and vibration, an elastic expansion sleeve should be selected. Considering the vibration reduction, buffering effect and economy, a non-metallic elastic element elastic expansion sleeve is recommended. In the transmission of the shaft system, there is generally a certain degree of relative offset between the two shafts. In such cases, a flexible expansion sleeve should be selected. The connection form of the coupling is determined by the connection form between the driving shaft and the driven shaft. The connection method adopted is key connection. The selection of the coupling should again comprehensively consider various factors. The size, torque, shaft diameter, and shaft hole of the coupling should all be matched with the prime mover and the working machine, and be able to adapt to the working environment. In the transmission of the shaft system, there is generally a certain degree of relative offset between the two shafts. In such cases, a flexible expansion sleeve should be selected. The connection form of the coupling is determined by the connection form between the driving shaft and the driven shaft. The connection method adopted is key connection. The selection of the coupling should again take into account various factors comprehensively. The size, torque, shaft diameter, and shaft hole of the coupling are all matched with the prime mover and the working machine. When the shafts need to be connected to transmit power, a belt pulley or a gear is usually used for connection. If the two shafts need to be on the same straight line and rotate at the same speed, a coupling is used for connection. Due to processing accuracy, thermal expansion of the shaft, or bending of the shaft under operation force, the concentricity between the two shafts will change. Therefore, a coupling can be used as a bridge to maintain the power transmission between the two shafts.

-

2025.06.27The order of 13 universal shafts was successfully completed, and the delivery efficiency and quality were highly praised by the customer.Recently, our company successfully completed the production task of 13 custom universal shafts for a client. From raw material procurement to finished product delivery, we strictly controlled the quality throughout the process. The production cycle was shorter than expected, demonstrating our outstanding manufacturing capabilities and efficient project management skills. The successful completion of this universal joint production order is inseparable from our company's advanced production technology and experienced technical team. During the manufacturing process, our company effectively enhanced the precision and durability of the universal joints by utilizing the existing advanced equipment, making all performance indicators exceed industry standards. The technical team also held multiple technical discussions and process optimizations in response to the special requirements raised by the customer, ensuring that each universal joint not only meets the customer's strict demands for working condition performance and dynamic balance but also guarantees the appearance performance and aesthetics of the product. The successful delivery of this order is not only a test of our production capacity, but also an important opportunity for us to establish a long-term cooperative relationship with the customer. Wang, the production director, said, "We always adhere to the customer-centered approach, constantly improving product quality and service levels, and are committed to providing customers with more high-quality solutions." This time, the client was extremely strict in choosing the supplier. Our company's successful bid and smooth delivery of the order fully demonstrate its technical strength and brand reputation in the field of universal joint manufacturing. After acceptance, the relevant person in charge of the client highly praised the product quality and expressed that they would continue to deepen cooperation with our company in the future. With the continuous growth in market demand for high-quality universal joints, our company will continue to increase investment in research and development, constantly improve our technological level and production capacity, and provide better products and services to meet market demands, contributing more to the development of the industry.

- Quick Links

- About

- Products

- Our Service

- News & Events

- Contact

- Products Series

- Flexible Couplings with Non-Elastic Elements

- Flexible Couplings with Metal Elastic Elements

- Flexible Couplings with Non-Metallic Elastic Elements

- Safety Coupling

- Rigid Coupling

- Contact Us

- Tel : +86 511 8572 3800 +86 511 8572 3900

- Mobile : +86 15106109009

- Email : [email protected]

- Add:No.1 Zhongye Yingbin Avenue, Gaozi Street, Dantu Economic Development Zone, Zhenjiang City, Jiangsu Province, China.

English

English