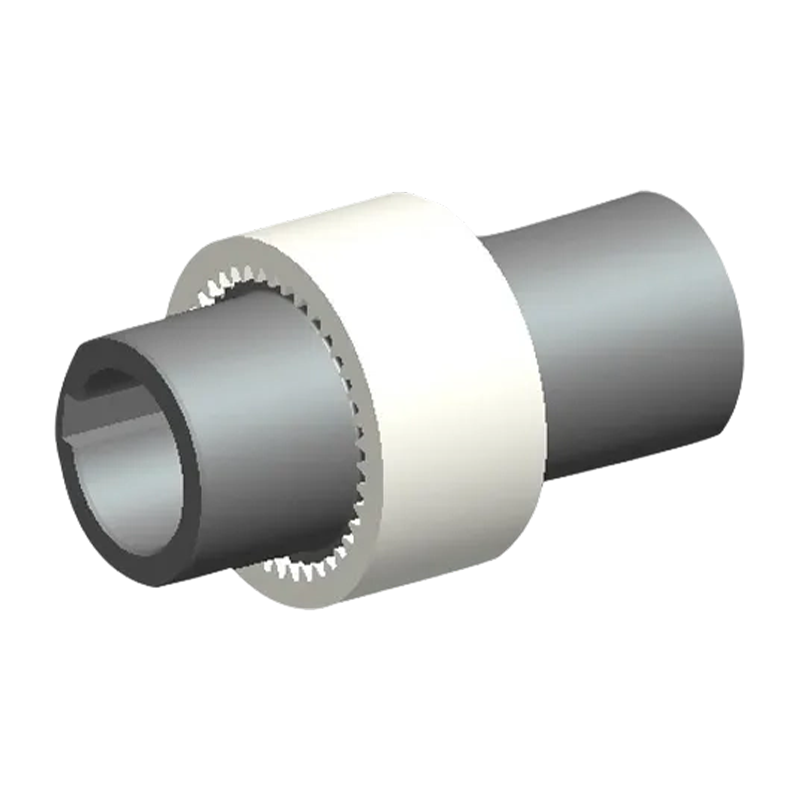

NC Nylon inner gear ring drum gear coupling(Q/YG14021X-2018)

The NC Nylon Inner Gear Ring Drum Gear Coupling represents a cutting-edge solution in mechanical power transmission, renowned for its innovative design, exceptional performance, and versatility across a wide range of industrial applications. Engineered to deliver reliable torque transmission while accommodating misalignments and dampening vibrations, this coupling stands as a pinnacle of efficiency and durability in the field.

At the heart of its design lies the utilization of nylon as a core material for the inner gear ring. Nylon, celebrated for its high strength, wear resistance, and self-lubricating properties, lends the coupling exceptional durability and operational longevity. This innovative use of material not only enhances the coupling's performance but also contributes to its ability to operate smoothly under various conditions, including high temperatures and corrosive environments.

The NC Nylon Inner Gear Ring Drum Gear Coupling features a unique drum-shaped design with internal gear teeth that engage seamlessly, ensuring precise torque transmission between connected shafts. This design not only facilitates high torque capacity but also enables the coupling to effectively compensate for angular, parallel, and axial misalignments, thereby reducing stress on connected equipment and extending their service life.

Furthermore, the coupling incorporates an elastomeric element between the inner and outer gears, serving as a cushion to absorb shocks and dampen vibrations during operation. This feature enhances the overall reliability of the coupling by minimizing the risk of damage to machinery and improving operational efficiency.

Installation and maintenance of the NC Nylon Inner Gear Ring Drum Gear Coupling are straightforward, thanks to its modular construction and user-friendly design. The coupling can be easily disassembled for inspection, repair, or replacement, minimizing downtime and optimizing productivity for industrial operations.

In summary, the NC Nylon Inner Gear Ring Drum Gear Coupling stands as a testament to innovation, reliability, and performance in mechanical power transmission. With its advanced design, durable construction, and exceptional capabilities, it remains a preferred choice for industrial applications where efficiency, durability, and versatility are paramount.

- Product Parameters

- Send Message

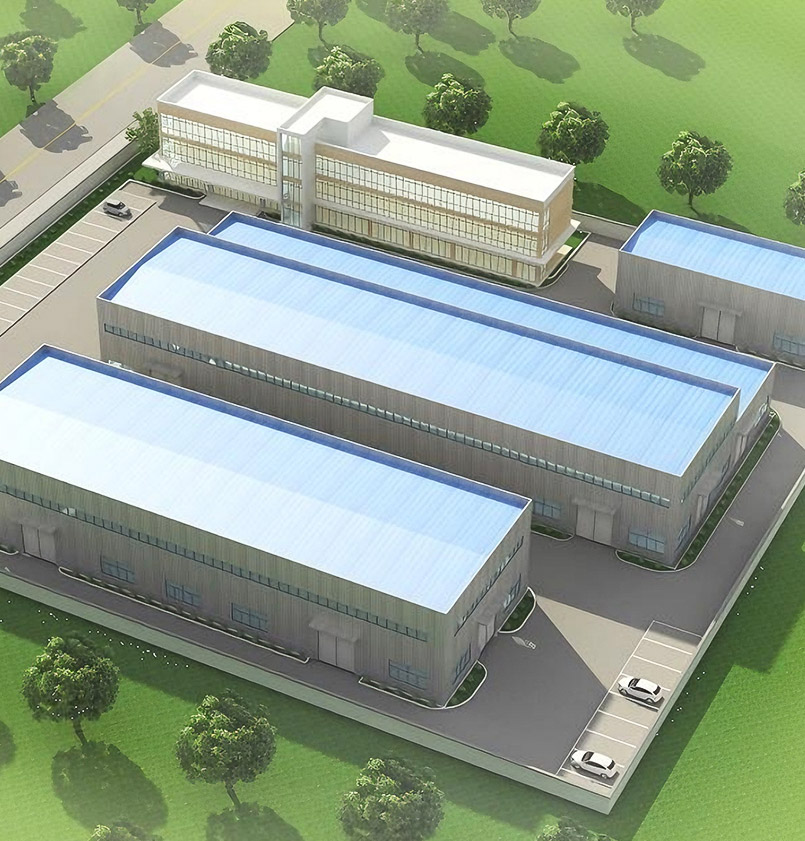

Zhongye Heavy Industry Technology (Zhenjiang) Co., Ltd. is located in a well-known ancient city, Zhenjiang. We are an enterprise integrating R & D, manufacturing, and sales. Our products are widely used in metallurgical equipment, mining equipment, water equipment, lifting equipment, paper equipment, port equipment and other industries.

Our main products are toothed coupling, elastic sleeve column pin coupling, elastic column pin coupling, gear coupling with elastic pin, a universal coupling, tire coupling, jaw coupling, star coupling, diaphragm coupling, drum coupling and grid coupling, the Oldham coupling, flange coupling, clip shell coupling, GL type roller chain coupling and a safety coupling, and so on. Our company also undertakes a variety of non - standard coupling designs and manufacturing.

New workshop covers an area of about 16463.52 m². heavy workshop 5,500 M2, Precision workshop 4,600 m² , office building and the gymnasium 2000 M2, Dinning hall 500m² , Warehouse 1000 m², Roads, greening, parking areas 3563 M2.

English

English