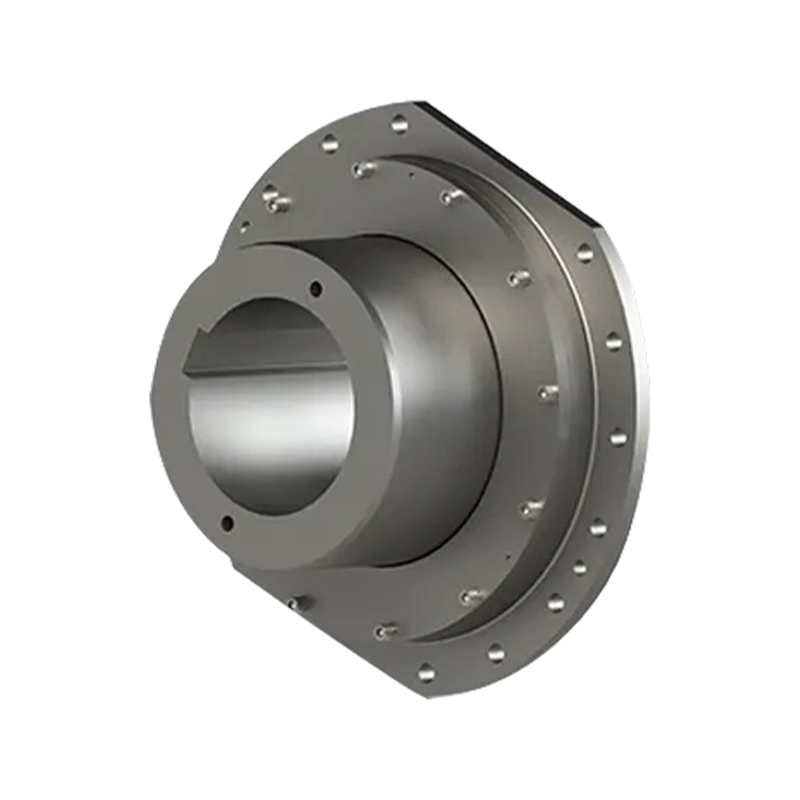

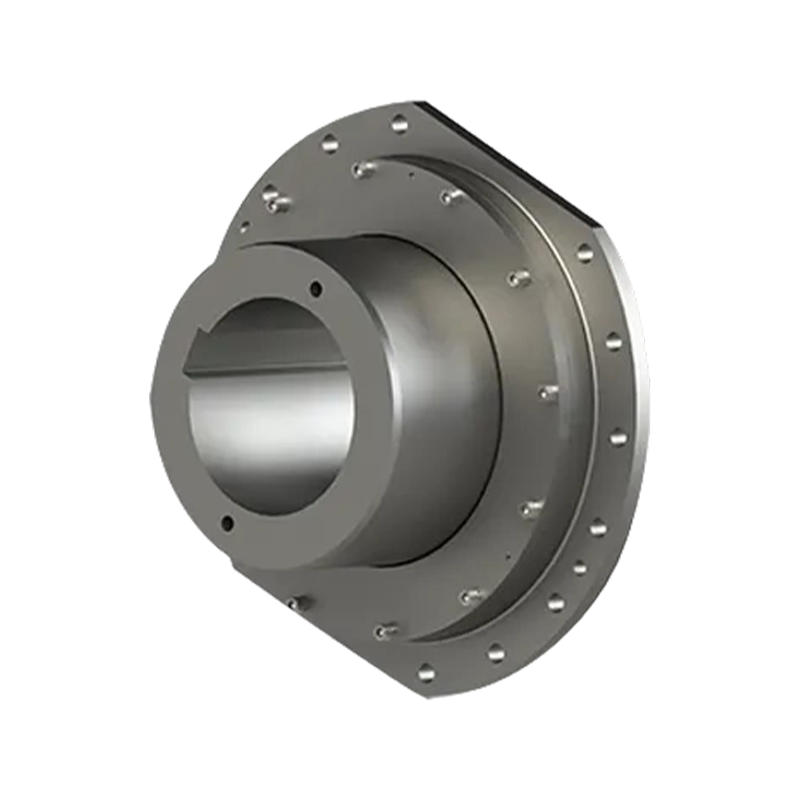

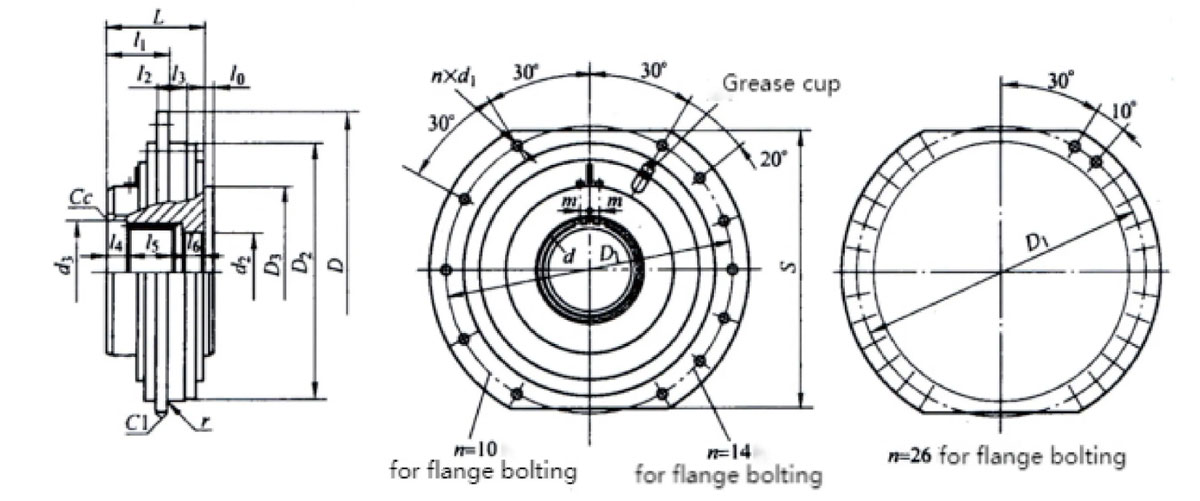

QGC type involute spline coupling spherical roller coupling(Q/YJ16029X-2018)

The QGC drum coupling is a spherical roller heavy-duty transmission component. Its core design consists of spherical rollers and a cycloidal spline. It is suitable for connecting drums and reducers in cranes, metallurgy, and other applications, and features strong load-bearing capacity, angular displacement compensation, low additional bending moment, and convenient maintenance. Here are its detailed performance characteristics:

Core performance characteristics

Excellent heavy-duty transmission and radial load-bearing: Spherical rollers are evenly distributed to transfer torque, with nominal torque ranging from 4kN·m to 900kN·m, and the allowable radial force reaching 16.5kN to 520kN. It is compatible with M3-M8 multiple working grades and can withstand frequent start-stop and impact conditions, with a 30% increase in bearing capacity compared to traditional tooth couplings.

Moderate angular displacement compensation capability: The spherical contact between the spherical rollers and the holes can compensate for angular displacements up to 1.5°, suitable for installation errors and frame deformations, reducing the requirements for shaft alignment accuracy and avoiding concentrated additional stress.

Low additional bending moment and high stability: The spherical contact also functions as a self-aligning bearing, significantly reducing the additional bending moment on the output shaft of the reducer and reducing the fatigue risk of the shaft system; the cycloidal spline transmission is smooth and has low operating noise, and is equipped with a wear indicator device for easy condition monitoring.

Reliable safety and protection: The spherical roller anti-detachment structure and sealing system can prevent the rollers from detaching, avoiding leakage of lubricating oil and the intrusion of impurities, ensuring the transmission safety in heavy-duty conditions.

Easy installation and maintenance: The combined design of the cycloidal spline and spherical rollers allows for a certain installation deviation, shortening the commissioning cycle; the modular structure facilitates disassembly and replacement of easily damaged parts such as rollers, with low maintenance costs and suitability for limited space drum arrangements.

Compact and efficient structure: The optimized axial and radial dimensions enable high torque and radial load-bearing in a limited space, meeting the requirements for compact layout of heavy equipment.

- Product Parameters

- Send Message

Zhongye Heavy Industry Technology (Zhenjiang) Co., Ltd. is located in a well-known ancient city, Zhenjiang. We are an enterprise integrating R & D, manufacturing, and sales. Our products are widely used in metallurgical equipment, mining equipment, water equipment, lifting equipment, paper equipment, port equipment and other industries.

Our main products are toothed coupling, elastic sleeve column pin coupling, elastic column pin coupling, gear coupling with elastic pin, a universal coupling, tire coupling, jaw coupling, star coupling, diaphragm coupling, drum coupling and grid coupling, the Oldham coupling, flange coupling, clip shell coupling, GL type roller chain coupling and a safety coupling, and so on. Our company also undertakes a variety of non - standard coupling designs and manufacturing.

New workshop covers an area of about 16463.52 m². heavy workshop 5,500 M2, Precision workshop 4,600 m² , office building and the gymnasium 2000 M2, Dinning hall 500m² , Warehouse 1000 m², Roads, greening, parking areas 3563 M2.

English

English