LCB type tire coupling(Q/YC 34010X-2018)

The LCB type is a skeleton-supported integral convex-type tire coupling. Its key features are as follows.

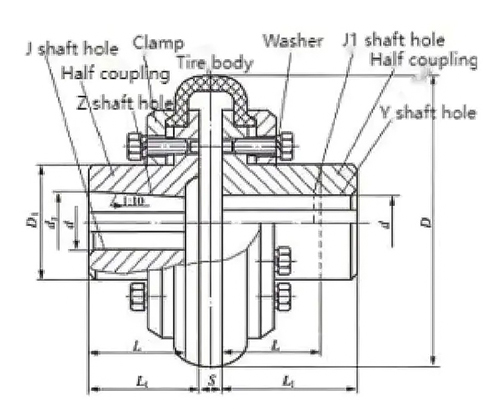

1. High elasticity and strong vibration reduction: The rubber tire body is integrated with the steel frame through vulcanization. The torsional stiffness is low, and the vibration and buffering capabilities are excellent. It can absorb heavy-load impacts and frequent start-stop vibrations, protecting the motor/gearbox.

2. Large compensation capacity: It can compensate for axial displacement of ±5 to ±10mm, radial displacement of 1 to 5 mm, and angular displacement of 1.5° to 3°, adapting to installation errors and working condition deformations.

3. Reliable transmission of heavy loads: The frame enhances the bearing capacity. The nominal torque coverage is wide (up to tens of thousands of N·m), with no torsional clearance. The power transmission is stable under forward and reverse rotation and variable loads.

4. Maintenance-free and easy installation: No lubrication required. The tire body is bolted to the semi-adapter. Installation and disassembly are convenient. The working temperature ranges from -20°C to +80°C, suitable for harsh working conditions such as humidity, dust, and corrosion.

5. Stable structure and long service life: The steel frame enhances the tire body's resistance to tearing and aging, making it more durable than the frameless type. It is suitable for long-term continuous operation.

6. Limitations: It is not suitable for excessive radial loads. For high-speed conditions (>3000 rpm), verification is required. Avoiding overheating and aging of the tire body is necessary.

Summary

The high elasticity rubber belt-structured coupling with a steel frame offers large compensation, strong vibration reduction, and maintenance-free features. It is the preferred flexible coupling for heavy-load impacts and harsh environments.

- Product Parameters

- Send Message

Zhongye Heavy Industry Technology (Zhenjiang) Co., Ltd. is located in a well-known ancient city, Zhenjiang. We are an enterprise integrating R & D, manufacturing, and sales. Our products are widely used in metallurgical equipment, mining equipment, water equipment, lifting equipment, paper equipment, port equipment and other industries.

Our main products are toothed coupling, elastic sleeve column pin coupling, elastic column pin coupling, gear coupling with elastic pin, a universal coupling, tire coupling, jaw coupling, star coupling, diaphragm coupling, drum coupling and grid coupling, the Oldham coupling, flange coupling, clip shell coupling, GL type roller chain coupling and a safety coupling, and so on. Our company also undertakes a variety of non - standard coupling designs and manufacturing.

New workshop covers an area of about 16463.52 m². heavy workshop 5,500 M2, Precision workshop 4,600 m² , office building and the gymnasium 2000 M2, Dinning hall 500m² , Warehouse 1000 m², Roads, greening, parking areas 3563 M2.

English

English