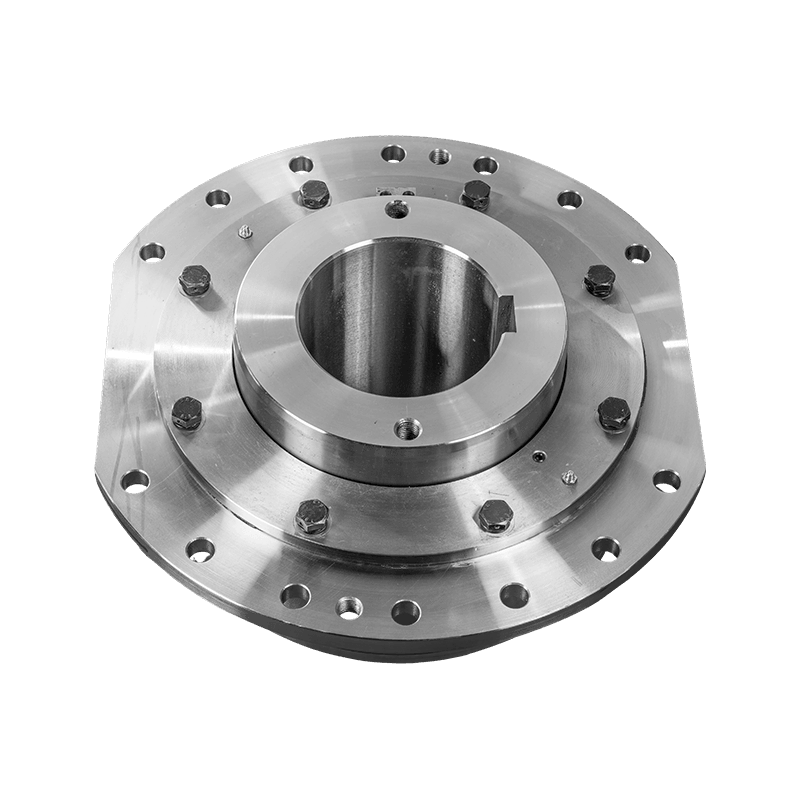

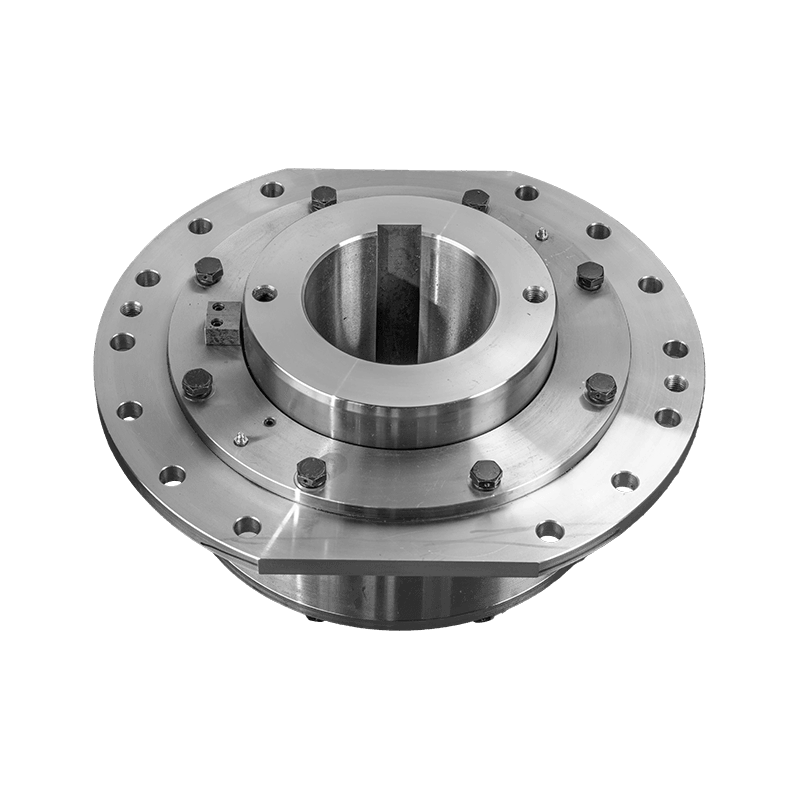

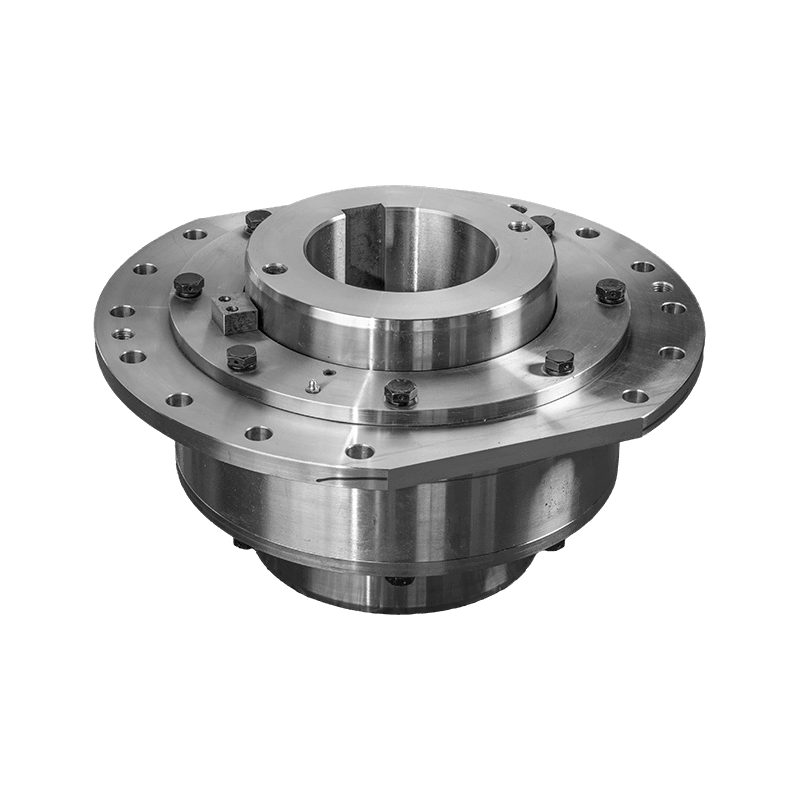

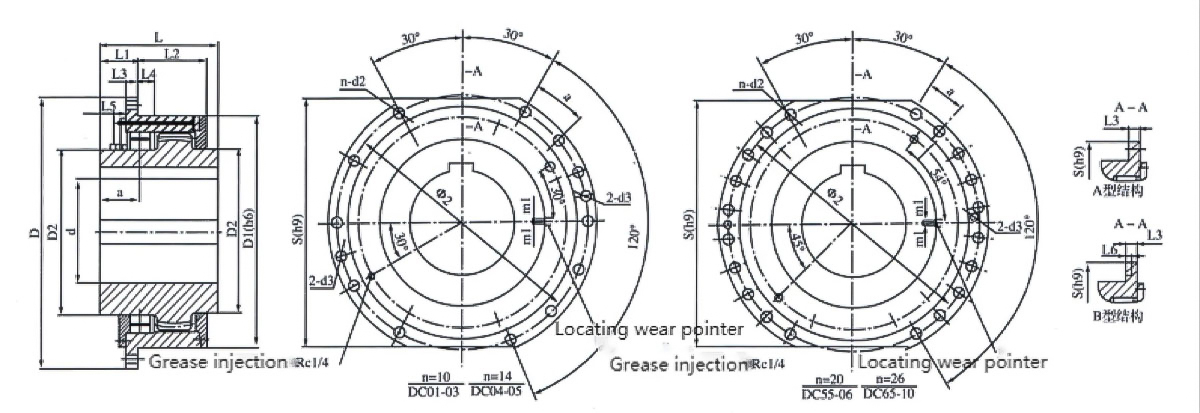

GJC drum coupling(Q/YJ 16028X-2018)

The GJC type drum coupling is a high-performance transmission component specially designed for the drums of lifting machinery (such as cranes and hoists). Its main features are as follows:

1. Suitable angle compensation capability

With a drum-shaped tooth design, it allows for a significant angular displacement between the two axes (typically ±0.5°). This is highly adaptable to installation errors of the drum axis and the reducer axis in lifting machinery, as well as dynamic skew during operation.

2. High load-bearing capacity and rigidity

It has a high torque transmission capacity, a compact structure, and can withstand large impact loads and vibrations, meeting the heavy-load requirements of lifting operations.

3. Excellent lubrication and sealing

It is usually equipped with reliable sealing devices, which can effectively prevent lubricant leakage and the entry of dust and water, extending the service life of the tooth surface.

4. Convenient installation and maintenance

The design usually allows for a certain degree of adjustment under load and some models support axial installation or disassembly, facilitating maintenance in a confined space.

5. Special drum connection method

Specifically designed for the drum, it usually adopts direct connection between the inner tooth ring and the drum housing (welding or bolt connection), and the outer tooth sleeve is connected to the output shaft of the reducer to achieve the drive of the drum.

Summary: The GJC type coupling combines the flexibility of drum-shaped gears with the rigidity for heavy loads, and is a crucial component in the drive system of hoisting machinery drum.

- Product Parameters

- Send Message

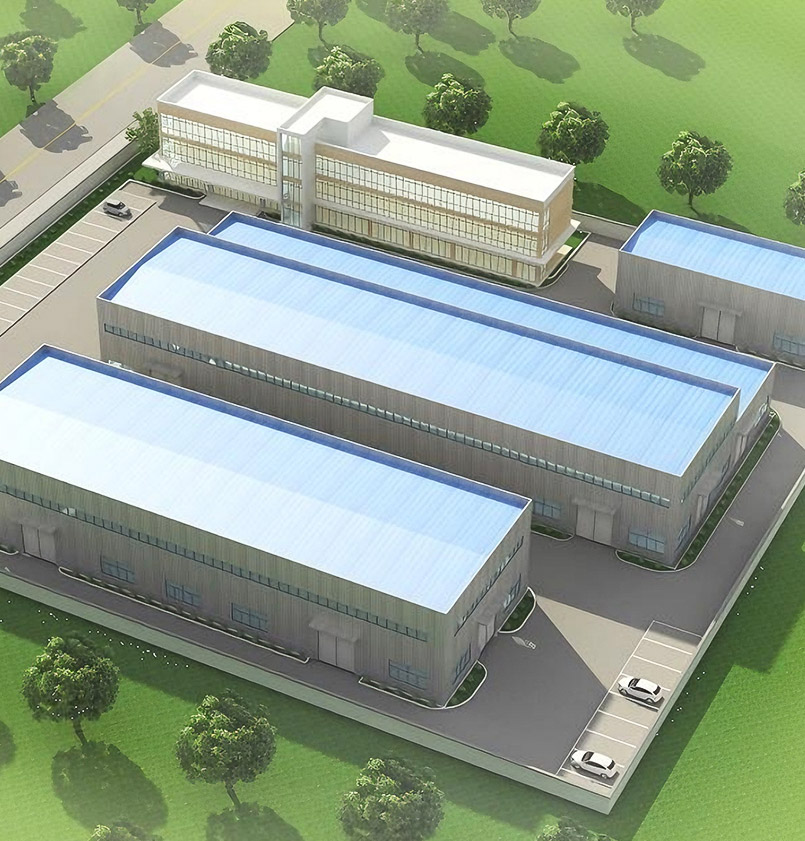

Zhongye Heavy Industry Technology (Zhenjiang) Co., Ltd. is located in a well-known ancient city, Zhenjiang. We are an enterprise integrating R & D, manufacturing, and sales. Our products are widely used in metallurgical equipment, mining equipment, water equipment, lifting equipment, paper equipment, port equipment and other industries.

Our main products are toothed coupling, elastic sleeve column pin coupling, elastic column pin coupling, gear coupling with elastic pin, a universal coupling, tire coupling, jaw coupling, star coupling, diaphragm coupling, drum coupling and grid coupling, the Oldham coupling, flange coupling, clip shell coupling, GL type roller chain coupling and a safety coupling, and so on. Our company also undertakes a variety of non - standard coupling designs and manufacturing.

New workshop covers an area of about 16463.52 m². heavy workshop 5,500 M2, Precision workshop 4,600 m² , office building and the gymnasium 2000 M2, Dinning hall 500m² , Warehouse 1000 m², Roads, greening, parking areas 3563 M2.

English

English