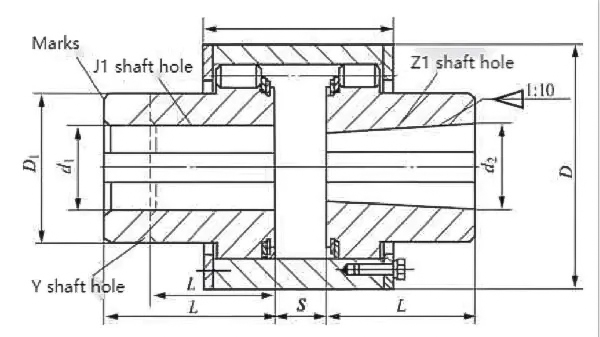

ZCD type conical shaft hole elastic pin gear coupling(Q/YZ33007X-2018)

ZCD type conical shaft hole elastic pin gear coupling Core Feature

1. Excellent cone hole fit: One end is a conical shaft hole, which is tightened by the conical surface, achieving high alignment accuracy and convenient installation and disassembly. It is suitable for direct connection with the conical output shaft of the motor/gear reducer, ensuring stable and reliable torque transmission.

2. Heavy-duty and efficient torque transmission: The nominal torque range is wide (up to several hundred thousand N·m), with a smaller turning diameter, smaller volume, and lighter weight under the same torque, which can partially replace the tooth-type coupling.

3. Three-dimensional compensation capability: The elastic pin and the tooth groove can compensate for axial (about 1.5~2.5mm), radial (about 0.3~0.6mm), and angular (about 0.5°) deviations, adapting to installation errors and working condition deformations.

4. Maintenance-free and low noise: The nylon pin is self-lubricating, requiring no additional lubrication, and is clean and environmentally friendly; the structure is simple, and the pin can be replaced by removing the guard plate, with low maintenance costs.

5. Simple structure and easy manufacturing: Few parts, no high-precision gear processing required, short manufacturing cycle, and lower cost.

6. Working conditions and limitations: Working temperature range is -20℃ to +70℃, suitable for general machinery with medium to heavy loads and frequent start-stop;vibration and noise reduction are average, not suitable for occasions with strict requirements for vibration/noise control, high speed, or extreme temperatures.

7. Overload protection: When overloaded, the elastic pin can deform or break to protect the main transmission components (such as the motor, reducer).

Summary

With the conical shaft hole, high-precision alignment and convenient assembly/disassembly are achieved. It also features heavy-load transmission and torsion, as well as three-element compensation. It is lubrication-free and easy to maintain, making it a cost-effective choice for medium and heavy-duty conical shaft extension systems.

- Product Parameters

- Send Message

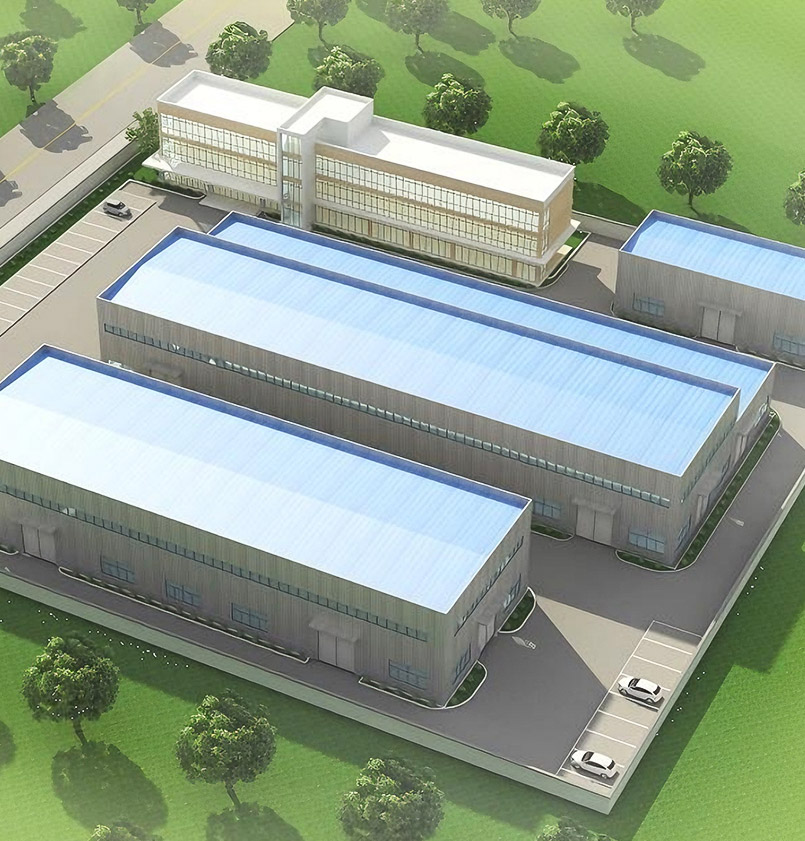

Zhongye Heavy Industry Technology (Zhenjiang) Co., Ltd. is located in a well-known ancient city, Zhenjiang. We are an enterprise integrating R & D, manufacturing, and sales. Our products are widely used in metallurgical equipment, mining equipment, water equipment, lifting equipment, paper equipment, port equipment and other industries.

Our main products are toothed coupling, elastic sleeve column pin coupling, elastic column pin coupling, gear coupling with elastic pin, a universal coupling, tire coupling, jaw coupling, star coupling, diaphragm coupling, drum coupling and grid coupling, the Oldham coupling, flange coupling, clip shell coupling, GL type roller chain coupling and a safety coupling, and so on. Our company also undertakes a variety of non - standard coupling designs and manufacturing.

New workshop covers an area of about 16463.52 m². heavy workshop 5,500 M2, Precision workshop 4,600 m² , office building and the gymnasium 2000 M2, Dinning hall 500m² , Warehouse 1000 m², Roads, greening, parking areas 3563 M2.

English

English