MP diaphragm coupling(Q/YP 21001X-2018)

Structural performance

1. According to the transmission torque and flexibility of the sizes of four, six, eight, ten, and twelve divided waist forms.

2. large bearing capacity, wide range of application, long life, transfer nominal torque of 0.063-10000KN.m.

3. The operating temperature of -40℃to +250℃, and no lubrication, can work in corrosive media.

4. Compared with the gear coupling, the simple structure, easy processing, maintenance, small vibration, no noise, and suitability for high-speed use.

5. easy to install and disassemble, check, disassemble the main and slave parts of the transmission system can be removed without axial displacement. Widely used in metallurgy, steel rolling, mining, the chemical industry, shipbuilding, pumps, fans, and other industries.

MP Diaphragm Coupling: A Comprehensive Profile

Introduction

The MP Diaphragm Coupling is a specialized mechanical device designed to connect two rotating shafts, enabling the transmission of torque and rotational motion. This coupling is known for its precision, high torque capacity, and ability to accommodate various forms of misalignment without sacrificing performance. It is an essential component in many industrial applications where reliability and efficiency are paramount.

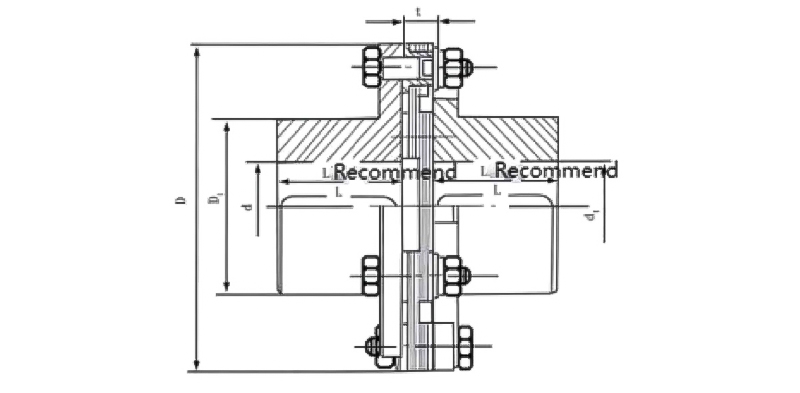

Design and Construction

The MP Diaphragm Coupling is constructed with several key components that work together to provide optimal performance:

- Diaphragm Pack: The central feature of the coupling, consisting of multiple thin metal diaphragms made from high-strength materials such as stainless steel. These diaphragms are flexible enough to handle misalignment but strong enough to transmit significant torque.

- Hubs: These are the end pieces that connect to the shafts. Made from durable materials like steel or aluminum, hubs ensure secure attachment and efficient torque transmission.

- Fasteners: High-precision bolts and screws are used to attach the diaphragm pack to the hubs, ensuring a tight and secure connection that maintains the integrity of the coupling.

Features and Benefits

- High Torque Capacity: MP Diaphragm Couplings are engineered to handle high levels of torque, making them ideal for heavy-duty applications.

Misalignment Accommodation: The design allows for compensation of angular, axial, and radial misalignment, protecting machinery from stress and potential damage. - Minimal Maintenance: The coupling's design eliminates the need for regular maintenance, reducing downtime and operational costs.

Precision and Reliability: Ensures consistent performance, which is crucial in applications that require high precision, such as aerospace and energy sectors. - High-Speed Operation: The balanced and lightweight construction enables the coupling to operate at high speeds with minimal vibration, enhancing the efficiency and lifespan of connected equipment.

Applications

MP Diaphragm Couplings are utilized across various industries due to their robustness and versatility:

- Aerospace: Used in connecting engines to gearboxes, where reliable performance under extreme conditions is essential.

- Power Generation: Employed in turbines and generators for their ability to handle high torque and ensure reliability.

- Petrochemical: Utilized in pumps and compressors where precision and the ability to accommodate misalignment are critical.

- Marine: Applied in propulsion systems requiring high torque capacity and durability.

Installation and Maintenance

While MP Diaphragm Couplings are designed to be maintenance-free, proper installation is crucial for optimal performance. This involves precise alignment of the shafts and secure fastening of the coupling components. Regular inspections, although infrequent, help ensure that the coupling remains in excellent condition and performs reliably throughout its service life.

Conclusion

The MP Diaphragm Coupling stands out as a sophisticated and essential component in mechanical systems, offering unmatched reliability, high torque capacity, and the ability to handle misalignment. Its widespread use in critical industries underscores its importance in ensuring the smooth and efficient operation of machinery, making it a vital element in the field of mechanical engineering.

- Product Parameters

- Send Message

Zhongye Heavy Industry Technology (Zhenjiang) Co., Ltd. is located in a well-known ancient city, Zhenjiang. We are an enterprise integrating R & D, manufacturing, and sales. Our products are widely used in metallurgical equipment, mining equipment, water equipment, lifting equipment, paper equipment, port equipment and other industries.

Our main products are toothed coupling, elastic sleeve column pin coupling, elastic column pin coupling, gear coupling with elastic pin, a universal coupling, tire coupling, jaw coupling, star coupling, diaphragm coupling, drum coupling and grid coupling, the Oldham coupling, flange coupling, clip shell coupling, GL type roller chain coupling and a safety coupling, and so on. Our company also undertakes a variety of non - standard coupling designs and manufacturing.

New workshop covers an area of about 16463.52 m². heavy workshop 5,500 M2, Precision workshop 4,600 m² , office building and the gymnasium 2000 M2, Dinning hall 500m² , Warehouse 1000 m², Roads, greening, parking areas 3563 M2.

English

English