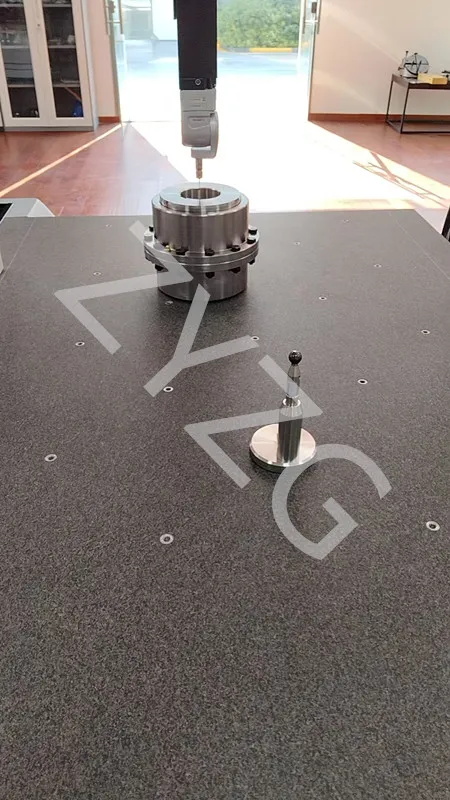

Three-coordinate measurement of keyway shape and position tolerance

The function of using a CMM to detect the geometric tolerances of couplings is mainly reflected in the following aspects:

1. Ensure Product Quality

By detecting geometric tolerances such as coaxiality, parallelism, and roundness of couplings, it ensures that their geometric features meet the design requirements, avoiding functional failure of parts due to excessive geometric errors. For example, excessive coaxiality error will cause additional vibration and noise when the coupling transmits power, accelerating equipment wear.

2. Improve Assembly Precision

Accurate geometric tolerance detection can provide data support for the assembly of couplings, ensuring the assembly precision between couplings and shafts, bearings and other components, making the mechanical cooperation during equipment operation closer, and reducing the risk of energy loss and component damage caused by assembly clearance.

3. Optimize Production Process

Based on the detection results, problems existing in the production process, such as insufficient machine tool precision and wear of tooling fixtures, can be analyzed, so as to optimize processing technology parameters, improve equipment and tooling, and improve production efficiency and product consistency.

4. Support Fault Diagnosis

When the equipment has faults such as vibration and abnormal noise, by using a CMM to detect the geometric tolerances of the coupling, it can be judged whether the fault is caused by the geometric error of the coupling, providing a basis for equipment fault diagnosis and maintenance, and shortening the fault troubleshooting time.

English

English