MPJ type diaphragm coupling with intermediate shaft type (Q/YP 21002X-2018)

Overview

The MPJ type diaphragm coupling with intermediate shaft type is a high-performance mechanical component designed to connect two shafts in a power transmission system, ensuring the transfer of torque while accommodating misalignment between the shafts. This coupling type is particularly useful in applications requiring long-distance shaft connections and offers several advantages, including high torsional rigidity, low maintenance, and the ability to handle high rotational speeds.

Design and Construction

1. Diaphragm Elements:

The core feature of the MPJ type coupling is its diaphragm elements. These are thin, flexible metal plates that allow for slight bending and axial movement while maintaining a high degree of torsional rigidity. The diaphragms are designed to handle misalignments such as angular, axial, and parallel misalignments.

2. Intermediate Shaft:

The inclusion of an intermediate shaft allows the coupling to span larger distances between the connected machinery. This intermediate shaft is typically made from high-strength materials to ensure durability and reliability under various operating conditions.

3. Hub and Flanges:

The coupling consists of hubs that attach to the respective shafts and flanges that secure the diaphragms in place. These components are precision-engineered to ensure a secure fit and optimal performance.

4. Bolts and Fasteners:

High-strength bolts and fasteners are used to assemble the diaphragm to the hubs and flanges, ensuring a robust and reliable connection capable of withstanding high levels of torque and rotational speed.

Key Features

1. Torsional Rigidity:

The MPJ type diaphragm coupling provides excellent torsional rigidity, making it ideal for applications where precise torque transmission is critical.

2. Misalignment Accommodation:

This coupling type effectively handles various types of misalignment, including angular, parallel, and axial displacement, without compromising performance.

3. Low Maintenance:

The design of the diaphragm coupling minimizes wear and tear, reducing the need for frequent maintenance and increasing the overall lifespan of the coupling.

4. High-Speed Capability:

The robust construction and precision engineering of the MPJ type diaphragm coupling make it suitable for high-speed applications, ensuring stable and reliable operation.

5. Corrosion Resistance:

Materials used in the construction of the coupling, such as stainless steel for diaphragms, provide excellent resistance to corrosion, making it suitable for use in harsh environments.

Applications

The MPJ type diaphragm coupling with intermediate shaft is used in various industries and applications, including:

- Power Generation: Connecting turbines and generators.

- Marine Engineering: Propulsion systems in ships and submarines.

- Aerospace: Transmitting power in aircraft systems.

- Industrial Machinery: High-speed compressors, pumps, and fans.

- Oil and Gas: Drilling rigs and processing equipment.

Installation and Maintenance

Alignment Check:

Before installation, it is crucial to ensure that the shafts are as aligned as possible to minimize stress on the coupling components.

Torque Tightening:

Proper torque tightening of bolts is necessary to maintain the integrity of the coupling assembly. Follow manufacturer specifications for torque settings.

Regular Inspections:

Periodic inspections should be conducted to check for any signs of wear or damage to the diaphragms and other components. Replace any worn parts as needed.

Lubrication:

Generally, the MPJ type diaphragm coupling does not require lubrication, which simplifies maintenance routines.

Conclusion

The MPJ type diaphragm coupling with intermediate shaft type is a versatile and reliable solution for long-distance shaft connections in high-performance applications. Its ability to handle misalignment, combined with its torsional rigidity and low maintenance requirements, makes it an excellent choice for a wide range of industrial and engineering applications.

- Product Parameters

- Send Message

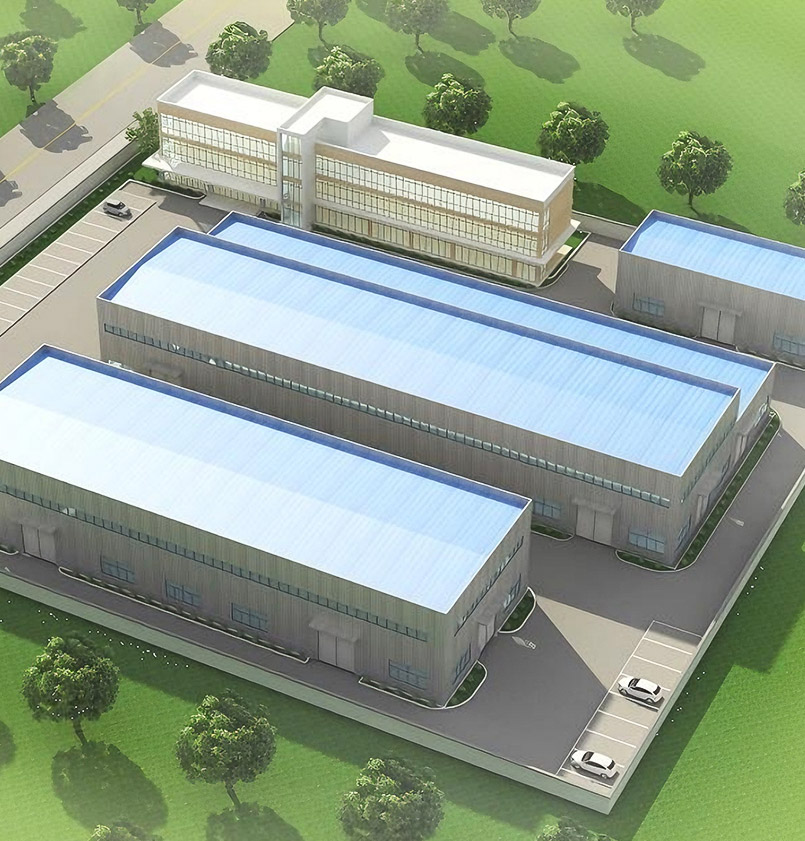

Zhongye Heavy Industry Technology (Zhenjiang) Co., Ltd. is located in a well-known ancient city, Zhenjiang. We are an enterprise integrating R & D, manufacturing, and sales. Our products are widely used in metallurgical equipment, mining equipment, water equipment, lifting equipment, paper equipment, port equipment and other industries.

Our main products are toothed coupling, elastic sleeve column pin coupling, elastic column pin coupling, gear coupling with elastic pin, a universal coupling, tire coupling, jaw coupling, star coupling, diaphragm coupling, drum coupling and grid coupling, the Oldham coupling, flange coupling, clip shell coupling, GL type roller chain coupling and a safety coupling, and so on. Our company also undertakes a variety of non - standard coupling designs and manufacturing.

New workshop covers an area of about 16463.52 m². heavy workshop 5,500 M2, Precision workshop 4,600 m² , office building and the gymnasium 2000 M2, Dinning hall 500m² , Warehouse 1000 m², Roads, greening, parking areas 3563 M2.

English

English