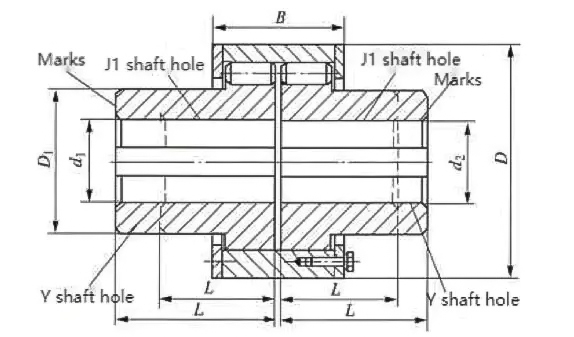

ZC type elastic pin gear coupling(Q/YZ33006X-2018)

ZC-type elastic pin gear coupling structural performance

1. The outer edge of the two half couplings and the inner edge of the jacket are made into a half-element groove with the same radius, which is combined into a pinhole to embed the pin. The driveshaft half coupling drives the jacket through the pin, and the jacket drives the driven shaft half-coupling through the pin to rotate to transfer torque.

2. The use of temperature -20℃-+70℃.

- Product Parameters

- Send Message

Zhongye Heavy Industry Technology (Zhenjiang) Co., Ltd. is located in a well-known ancient city, Zhenjiang. We are an enterprise integrating R & D, manufacturing, and sales. Our products are widely used in metallurgical equipment, mining equipment, water equipment, lifting equipment, paper equipment, port equipment and other industries.

Our main products are toothed coupling, elastic sleeve column pin coupling, elastic column pin coupling, gear coupling with elastic pin, a universal coupling, tire coupling, jaw coupling, star coupling, diaphragm coupling, drum coupling and grid coupling, the Oldham coupling, flange coupling, clip shell coupling, GL type roller chain coupling and a safety coupling, and so on. Our company also undertakes a variety of non - standard coupling designs and manufacturing.

New workshop covers an area of about 16463.52 m². heavy workshop 5,500 M2, Precision workshop 4,600 m² , office building and the gymnasium 2000 M2, Dinning hall 500m² , Warehouse 1000 m², Roads, greening, parking areas 3563 M2.

English

English