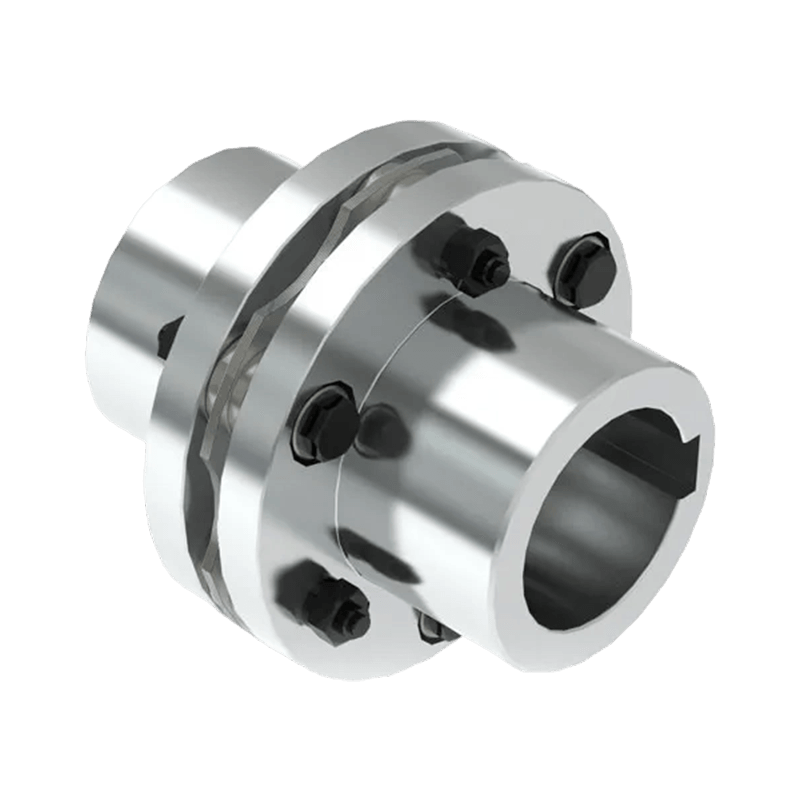

DMA single type elastic diaphragm coupling

Overview

The DMA Single Type Elastic Diaphragm Coupling is a highly efficient mechanical device designed to transmit torque between shafts while accommodating misalignment and reducing mechanical stresses. This coupling type is particularly valued for its high precision, reliability, and ability to handle significant loads and speeds. It is commonly used in various industrial applications, including power transmission in machinery, pumps, compressors, and other equipment requiring robust and precise torque transfer.

Design and Construction

The DMA Single Type Elastic Diaphragm Coupling features a unique design that incorporates a flexible diaphragm made from high-quality materials such as stainless steel. This diaphragm is the key component that provides flexibility and elasticity, allowing the coupling to compensate for misalignments between connected shafts. The main components of the coupling include:

- Diaphragm: Made of durable and elastic material, the diaphragm can handle angular, axial, and radial misalignments.

- Hubs: These are the parts that attach to the shafts. They are typically made from high-strength steel or other robust materials.

- Bolts and Bushings: High-tensile bolts and bushings secure the diaphragm to the hubs, ensuring a firm and reliable connection.

Key Features

- High Precision: The DMA coupling offers excellent precision in torque transmission, making it ideal for applications where accuracy is critical.

- Misalignment Compensation: It effectively compensates for various types of shaft misalignments, including angular, axial, and radial, reducing wear and tear on connected machinery.

- Vibration Damping: The elastic nature of the diaphragm helps to dampen vibrations, contributing to smoother operation and prolonging the lifespan of connected equipment.

- Maintenance-Free: Due to its robust design and high-quality materials, the coupling typically requires minimal maintenance.

- High Torque Capacity: The coupling can handle significant torque loads, making it suitable for heavy-duty applications.

Applications

The DMA Single Type Elastic Diaphragm Coupling is versatile and can be used in various industrial applications, such as:

- Pumps and Compressors: Ensuring reliable torque transmission while accommodating misalignment and reducing vibration.

- Machinery and Equipment: Used in general machinery where precision and reliability are essential.

- Power Generation: Applied in turbines and generators where high torque and alignment compensation are crucial.

- Marine and Automotive: Utilized in marine propulsion systems and high-performance automotive applications.

Advantages

- Durability and Longevity: Made from high-strength materials, the coupling can withstand harsh operating conditions and extend the service life of connected components.

- Improved Performance: By compensating for misalignment and dampening vibrations, the coupling enhances the overall performance and efficiency of machinery.

- Cost-Effective: Reducing the need for frequent maintenance and replacement lowers operational costs over time.

Selection Criteria

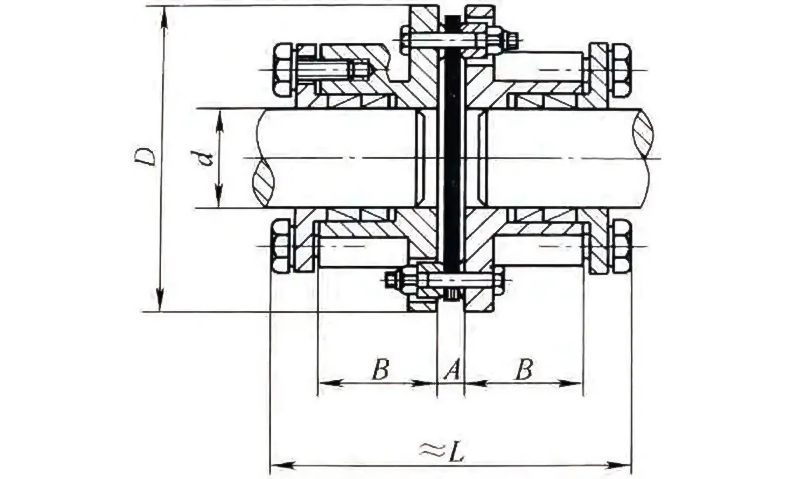

When choosing a DMA Single Type Elastic Diaphragm Coupling, consider the following factors:

- Torque Requirements: Ensure the coupling can handle the maximum torque of the application.

- Shaft Sizes: Verify compatibility with the shaft diameters and keyways.

- Misalignment Tolerance: Determine the level of misalignment the coupling needs to accommodate.

- Operating Conditions: Consider the environmental conditions, such as temperature, humidity, and potential exposure to corrosive substances.

In summary, the DMA Single Type Elastic Diaphragm Coupling is a reliable and efficient solution for various industrial applications requiring precise torque transmission, misalignment compensation, and vibration reduction. Its robust design and high-quality materials make it a preferred choice in many demanding environments.

- Product Parameters

- Send Message

Zhongye Heavy Industry Technology (Zhenjiang) Co., Ltd. is located in a well-known ancient city, Zhenjiang. We are an enterprise integrating R & D, manufacturing, and sales. Our products are widely used in metallurgical equipment, mining equipment, water equipment, lifting equipment, paper equipment, port equipment and other industries.

Our main products are toothed coupling, elastic sleeve column pin coupling, elastic column pin coupling, gear coupling with elastic pin, a universal coupling, tire coupling, jaw coupling, star coupling, diaphragm coupling, drum coupling and grid coupling, the Oldham coupling, flange coupling, clip shell coupling, GL type roller chain coupling and a safety coupling, and so on. Our company also undertakes a variety of non - standard coupling designs and manufacturing.

New workshop covers an area of about 16463.52 m². heavy workshop 5,500 M2, Precision workshop 4,600 m² , office building and the gymnasium 2000 M2, Dinning hall 500m² , Warehouse 1000 m², Roads, greening, parking areas 3563 M2.

English

English