Introduction: The HN type slider coupling is a precision-engineered mechanical coupling sy...

Don't hesitate to send a message

+86 511 8572 3900

+86 15106109009 Keep in touch

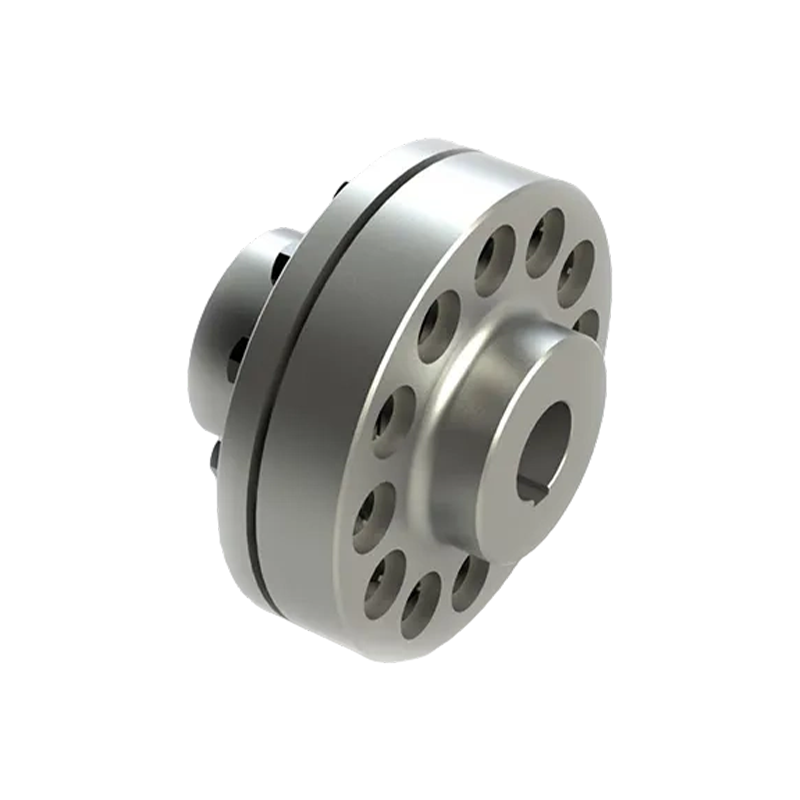

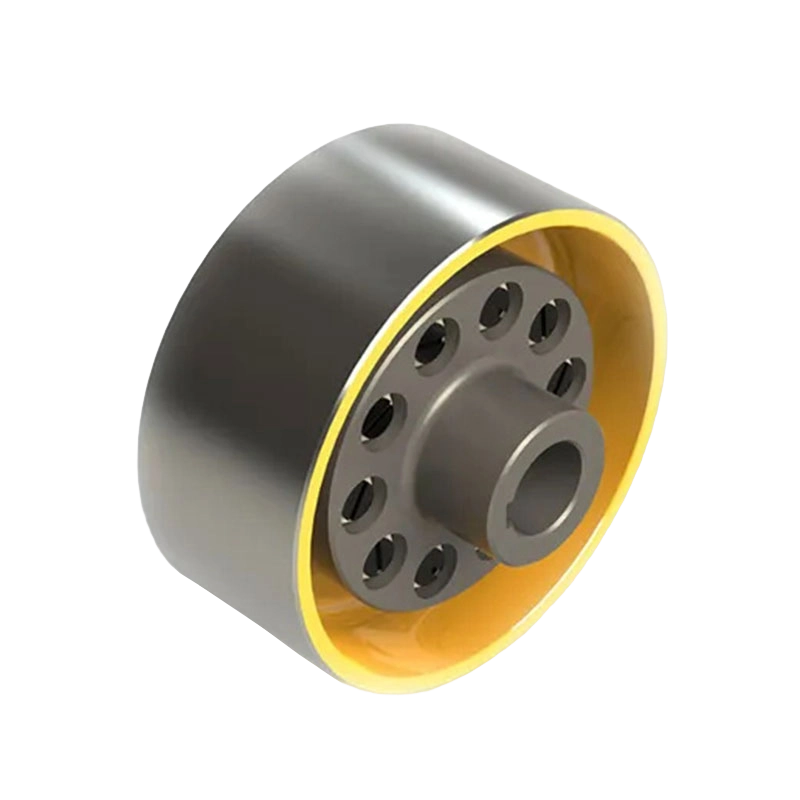

Flexible Couplings with Non-Elastic Elements

The flexible couplings with non-elastic elements compensate for shaft misalignment through relative movement or clearance between mating components, instead of elastic deformation.

Due to the absence of damping or buffering elements, these couplings offer high torsional stiffness and efficient power transmission, and are typically applied in systems operating under stable rotational speed and constant load conditions.

Our company supplies non-elastic elements flexible couplings in a broad range of sizes and specifications to meet different installation and operating requirements.

-

-

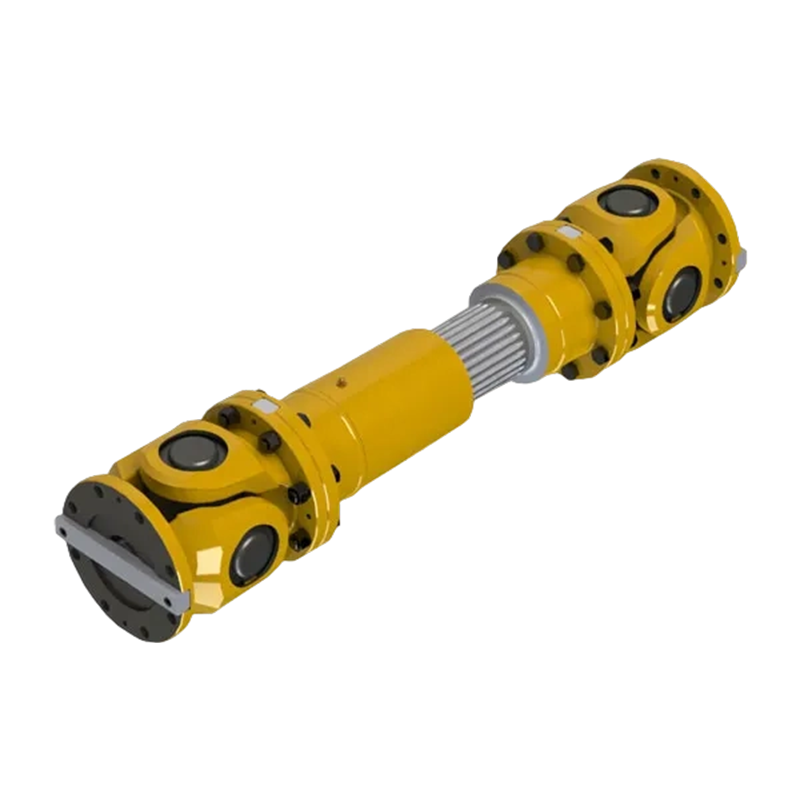

SWC-WF type large size universal coupling without expansion flange

SWC-WF type large size universal coupling without expansion flangeIntroduction: The SWC-WF Type Large Size Universal Coupling without Expansion Flange is an...

-

SWC-CH type long expansion welding universal coupling

SWC-CH type long expansion welding universal couplingIntroduction: The SWC-CH Type Long Expansion Welding Universal Coupling embodies a sophist...

-

SWC-WD non-telescopic short universal coupling

SWC-WD non-telescopic short universal couplingIntroduction: The SWC-WD Non-Telescopic Short Universal Coupling is a precision-engineered...

-

QWL Type Ball Cage Universal Coupling

QWL Type Ball Cage Universal CouplingCore Characteristics and Application Analysis of QWL-type Ball Cage Universal CouplingThe ...

-

SWC-WH type non-expansion welded universal coupling

SWC-WH type non-expansion welded universal couplingIntroduction: The SWC-WH Type Non-Expansion Welded Universal Coupling represents a versati...

-

SWC-DH type short expansion welding universal coupling

SWC-DH type short expansion welding universal couplingThe SWC-DH Type Short Expansion Welding Universal Coupling is a cutting-edge solution desi...

-

SWC-BF large size standard expansion flange universal coupling

SWC-BF large size standard expansion flange universal couplingThe SWC-BF Large Size Standard Expansion Flange Universal Coupling represents a pinnacle i...

-

SWC-BF standard expansion flange type universal coupling

SWC-BF standard expansion flange type universal couplingThe SWC Standard Telescopic Flange Type Universal Joint Coupling is an advanced engineerin...

-

SWC-BH standard expansion welded universal coupling

SWC-BH standard expansion welded universal couplingThe SWC Standard Telescopic Welded Universal Joint Coupling is a versatile and reliable so...

-

SWC-WF type flange universal coupling without expansion welding

SWC-WF type flange universal coupling without expansion weldingIntroduction: The SWC-WF Type Flange Universal Coupling without Expansion Welding is a pre...

Zhongye Heavy Industry Technology (Zhenjiang) Co., Ltd. is located in a well-known ancient city, Zhenjiang. We are an enterprise integrating R & D, manufacturing, and sales. Our products are widely used in metallurgical equipment, mining equipment, water equipment, lifting equipment, paper equipment, port equipment and other industries.

Our main products are toothed coupling, elastic sleeve column pin coupling, elastic column pin coupling, gear coupling with elastic pin, a universal coupling, tire coupling, jaw coupling, star coupling, diaphragm coupling, drum coupling and grid coupling, the Oldham coupling, flange coupling, clip shell coupling, GL type roller chain coupling and a safety coupling, and so on. Our company also undertakes a variety of non - standard coupling designs and manufacturing.

New workshop covers an area of about 16463.52 m². heavy workshop 5,500 M2, Precision workshop 4,600 m² , office building and the gymnasium 2000 M2, Dinning hall 500m² , Warehouse 1000 m², Roads, greening, parking areas 3563 M2.

-

2025.09.26The Role of Drum Couplings in the Lifting IndustryThe core function of drum couplings in the lifting industry is transmitting power and compensating for deviations. They connect the crane's drive motor (or reducer) to the drum, ensuring stable power transmission for lifting/lowering heavy loads while adapting to displacement errors during installation and operation. Its key roles can be broken down into two points: 1. Core of Power Transmission: Acting as a "power bridge", it accurately transmits the torque from the drive unit to the drum, driving the drum to rotate and realize the winding/unwinding of the steel wire rope. This is the direct power link for the crane to achieve lifting functions. 2. Deviation Compensation & Protection: uring the operation of lifting equipment, the axes of the motor, reducer and drum may shift (such as radial or angular deviation) due to installation errors or load deformation. The coupling can absorb these deviations through its own structure (e.g., elastic components), avoiding damage to parts caused by hard impact and prolonging the service life of the equipment. I can help you translate the core technical parameter list for drum coupling selection (mentioned earlier) into English, which will include key indicators like torque, speed, and deviation compensation. Do you need me to do that?

-

2025.09.20The advantages and features of the elastic pin couplingThe elastic pin coupling is a device that inserts a semi-metallic elastic material column pin into the flange holes of two couplings, thereby achieving half of the coupling connection. The elastic element material is generally nylon, which has the ability to slightly compensate for the offset of the two shafts. The elastic element works under shear force and has poor working reliability, and is only suitable for medium-speed transmission shaft systems with lower reliability requirements. It is not suitable for working conditions with higher reliability requirements. Now, let's learn about the advantages and features of the elastic pin coupling. The elastic pin coupling is suitable for various coaxial transmission systems. It transmits torque using the cross-sectional shear strength of the nylon rods, with a nominal torque of 160 - 160,000 N.M, and a working temperature range of -20 - 80. The structure is simple, with buffering and vibration reduction capabilities and a certain ability to compensate for shaft offset. It is suitable for use in environments that do not suppress noise. The allowable correction amount is within an angle of 0.15 - 0.25 mm towards 0.5. The elastic pin coupling has the following features: 1. Due to the large torque transmission, under the same torque, it often has a smaller rotational diameter than the tooth coupling, is small in volume, and light in weight. It can partially replace the tooth coupling. 2. Compared with the tooth coupling, it has a simpler structure, fewer components, is easy to manufacture, and does not require a gear processing machine. 3. Maintenance is convenient, the lifespan is long, and the nylon column pin can be replaced by removing the baffle. 4. The nylon column pin is a self-lubricating material, does not require lubrication, which not only saves lubricating oil but also purifies the working environment. 5. The vibration energy reduction is poor, and the noise is high. Applicable scenarios for the elastic pin coupling: The elastic element of the elastic pin coupling generally uses nylon, which has the ability to slightly compensate for the offset of the two shafts. The elastic element works under shear force, and the working reliability is very poor. It is only suitable for medium-speed transmission shaft systems with lower reliability requirements and not suitable for working conditions with higher reliability requirements. Advantages of the elastic pin coupling: 1. The elastic pin coupling transmits torque through the frictional force generated by the tightening force of the column pin group on the contact surface, compressing the rubber elastic sleeve. It is suitable for installation in systems with a rigid base, medium to high installation height, small impact loads, and low vibration reduction requirements for small and medium power shaft systems. 2. The working of the elastic sleeve is compressed and deformed. Due to the thin thickness, small volume, and limited elastic deformation of the elastic sleeve, the elastic pin coupling can compensate for shaft line displacement and elasticity, but the allowable compensation amount for shaft line displacement is small, and the elasticity is weak. 3. The structure of the elastic pin coupling is simple, easy to manufacture, does not require lubrication, does not need to be sintered with metal, it is convenient to replace the elastic sleeve, does not require moving the half coupling, and can compensate for the relative misalignment of the two shafts and the vibration and buffering performance.

-

2025.09.05Limitations on the use of elastic couplings and the disassembly methodsThe elastic body of the elastic coupling is restricted by the convex claw-shaped blocks, which can avoid internal deformation caused by impact and external deformation caused by centrifugal force. The large concave surface of the convex claws results in very low surface pressure on the involute teeth, so even if the teeth are overloaded, they will not wear or deform. The elastic coupling uses engineering plastics as the elastic element, which has the functions of buffering, vibration reduction, wear resistance, and convenient disassembly. During the operation of the coupling joint, the force is transmitted through the pin and rubber ring, thus enabling it to have good vibration reduction and vibration absorption effects, and allowing for the use of the same coaxiality. During assembly, the coaxiality between the two shafts is controlled within 0.3mm, which can easily cause severe wear of the rubber ring, shorten its service life, and cause vibration, losing its original function. During the operation, the elastic coupling joint transmits torque through the pin and rubber ring, thus having good vibration reduction and vibration absorption effects, and allowing for the use of the same coaxiality. Before disassembly, the coaxiality between the two shafts is controlled within 0.3mm. This can easily cause severe wear of the rubber ring, shorten its service life, and cause vibration, losing its original function. Timely maintenance and replacement are required. Otherwise, it will cause severe vibration, affecting the normal operation of the locomotive. The rubber ring of the elastic coupling is prone to friction and burn damage due to the frequent rotational impact. Replacing the rubber ring of the elastic coupling joint requires disassembling the elastic pin, and disassembling the elastic pin requires special disassembly tools. Before disassembly, using traditional disassembly tools is prone to falling off, and at least two people need to collaborate during the replacement of the coupling rubber ring during locomotive maintenance operations. The working space between the auxiliary transmission is relatively narrow, and sometimes a crowbar, hand hammer, etc. are needed. The labor intensity of the on-site workers is high, which to a certain extent affects the normal maintenance efficiency of the locomotive. Therefore, the labor intensity of the maintenance work needs to be improved, the maintenance efficiency should be increased, the labor intensity should be reduced, and the disassembly time of the elastic pin of the coupling joint should be shortened, and the rubber ring should be replaced in time, so that the normal operation of the auxiliary transmission part can be maintained. During disassembly, the positive and reverse threads are used in combination to generate rotational friction problems. The rotational friction is transformed into relative static friction, which to a certain extent prevents the damage of the traditional tools caused by rotational friction. The initial phenomenon at the end of the nut can be disassembled. The important thing is that the coaxiality of the two shafts can be installed, which to a certain extent improves the service life of the rubber ring.

-

2025.08.29The function of the three-coordinate measuring instrument in relation to the couplingOur company has recently introduced an advanced three-coordinate measuring instrument. A three-coordinate measuring instrument (CMM) is a highly precise measuring device, widely used in manufacturing, aerospace, automotive manufacturing, and other fields. For the measurement and inspection of couplings, the three-coordinate measuring instrument plays the following important roles: 1. Dimension measurement: The three-coordinate measuring instrument can precisely measure various parameters of the coupling, such as length, width, height, angle, curvature, etc., with an accuracy of up to 0.001 millimeters. This is crucial for ensuring that the dimensions of the coupling meet the design requirements. 2. Shape and position detection: The three-coordinate measuring instrument can detect the geometric shape and positional relationship of the coupling, including roundness, parallelism, perpendicularity, etc., for geometric accuracy. These parameters are very important for the performance and installation of the coupling. 3. Profile accuracy measurement: The three-coordinate measuring instrument can precisely measure the profile of the coupling to ensure that its surface shape meets the design requirements. This is very important for ensuring the stability and reliability of the coupling during operation. 4. Automated measurement and data processing: The three-coordinate measuring instrument is equipped with high-precision probes and a computer control system, enabling automated measurement and data processing. This not only improves measurement efficiency but also reduces human errors. 5. Optical scanning of complex parts: For some complex-shaped couplings, the three-coordinate measuring instrument can measure them through optical scanning to obtain detailed three-dimensional data. This is very useful for the detection and quality control of complex parts. 6. Quality control: Using the measurement data from the three-coordinate measuring instrument, the quality of the coupling can be controlled to ensure it meets international standards and industry norms. This is of great significance for enhancing product competitiveness and market share. In mechanical manufacturing, the three-coordinate measuring instrument can be used to measure the geometric accuracy and profile accuracy of the coupling, ensuring its stability and reliability during operation.

-

2025.08.22How to Locate the Center Point of the Diaphragm Coupling and Analysis of Maintenance PrecautionsWhen the diaphragm coupling operates at high speed, the radial movement caused by centrifugal force leads to accelerated wear and increases the size of the housing. The diaphragm coupling not only prevents dust and oil, but also causes interference if the amount of thinning is insufficient. If it thins out, the strength of the teeth will weaken and the gap on the side will also increase. How to find the center point of a diaphragm coupling? According to the principle of measurement, the use of common measuring tools such as feeler gauges, dial indicators, and bridge meters, as well as the consideration of the data recording and calculation process after measurement, and based on the measurement results to create a status diagram, can accurately adjust the coupling and achieve the connection accuracy of the two shafts. The installation of the diaphragm coupling makes the line of one rotor shaft become a continuous curve of the other rotor shaft. Therefore, it is necessary to maintain the matching of the two lines. That is to say, the outer ring surfaces of the two pairs of wheels should be concentric, and the two pairs of mating surfaces should be parallel. Therefore, the center point should be found during the installation of the diaphragm coupling. The initial selected size of the diaphragm coupling should meet the requirements of the diameters of the main shaft and the driven shaft. Otherwise, the specifications of the diaphragm coupling need to be adjusted according to the diameter of the shaft. When the torque and rotational speed are the same but the diameters of the main shaft and the longitudinal shaft are different, the model can be selected based on the diameter of the main shaft. After choosing the model based on the nominal torque, connection form, shaft hole diameter and length, it is necessary to confirm whether the working speed, relative offset, etc. of the shaft are within the sufficient range of the selected diaphragm coupling, and perform strength checks on the shaft and key connections. In addition, the balance accuracy also needs to be determined. When designing the overall structure of the diaphragm coupling, attention should be paid to the lubrication, dust prevention and protection effect between the tooth surface and the roller. Because the breakage of the chain can cause personal accidents, and the curvature radius of the bell curve is proportional to the reduction amount of the internal teeth on one side. The following are the precautions to be noted during the maintenance of the diaphragm coupling: (1) Basic inspection requirements: The connection must be firm, the connecting bolts and connecting keys must not be loose, and there should be no obvious sensation of radial and end face jumps when the internal diameter and end face are transmitted visually. When using instruments for inspection, it should not be too large. (2) Gear safety inspection: When the transmission noise increases or during the precise inspection of the product, it should be removed for inspection. (3) Elasticity inspection: When the rubber ring and leather pad are damaged, they should be replaced as soon as possible. If the pin and the hole are damaged and vibration occurs, a certain angle of rotation of the half-body should be drilled once and a standard new pin should be replaced. The original hole should not be extended onto the new pin. (4) Problems such as incomplete sealing of the lubricating series oil, oil deterioration, oil leakage and running out. When any of the above situations occur, the oil should be shut off and replaced, and oil shortage should be replenished as soon as possible.

-

2025.08.15How to Select the Appropriate CouplingThe model of the coupling is generally selected based on the transmitted torque, rotational speed, allowable deviation, etc. When choosing a standard coupling, it is necessary to determine it based on the usage requirements and working conditions, such as the bearing capacity, rotational speed, relative displacement of the two shafts, buffering and vibration absorption, as well as the ease of disassembly, maintenance and replacement of the vulnerable drum-shaped tooth couplings. Comprehensive analysis should be conducted to make the determination. When making the selection, the following points can be considered in sequence: the factors to be considered when choosing a coupling. 1. Characteristics of the coupling devices of the prime mover and the working coupling. Depending on the type of the prime mover, the output power and speed vary. Some are stable, while others may have significant impacts or even intense vibrations. This directly affects the selection of the coupling type and is one of the primary bases for selection. For loads that are stable, considering the development trend of the industry, a rigid elastic pin coupling can be chosen; otherwise, a flexible elastic pin coupling or a TL type elastic sleeve pin coupling should be selected. 2. The shaft system connected by the coupling and its operating conditions. For shaft systems with large mass, large rotational inertia, and frequent starting, speed variation, or reversing, it is necessary to consider using an elastic cylindrical pin coupling that can withstand large instantaneous overload and also provide buffering and vibration absorption functions. 3. The rotational speed of the working coupling has an impact on the two-axis connection that requires high-speed operation. In such cases, it is necessary to consider selecting a coupling with a structure featuring high balance accuracy, in order to eliminate the vibration and noise caused by centrifugal force, and to reduce the wear and heat of the related bevel gear coupling, thereby lowering the transmission quality and service life. Among them, the diaphragm coupling has better adaptability to high-speed operation. Based on the magnitude of the transmitted load, the rotational speed of the shaft, the installation accuracy of the two connected components, and referring to the characteristics of various coupling types, select an appropriate coupling type. When making the specific choice, the following points can be considered: 1. The size and nature of the torque to be transmitted, as well as the requirements for buffering and vibration reduction functions. For example, for high-power and heavy-duty transmissions, gear couplings can be selected; for transmissions subject to severe impact loads or those requiring the elimination of shaft system torsional vibrations, elastic couplings such as tire-type couplings can be chosen, which have high elasticity. 2. The rotational speed of the coupling and the magnitude of the centrifugal force it generates. For high-speed transmission shafts, a coupling with high balance accuracy should be selected, such as a diaphragm coupling, rather than a sliding block coupling with eccentricity; 3. The magnitude and direction of the relative displacement between the two shafts. After installation and adjustment, it is difficult to maintain the strict and precise alignment of the two shafts, or during operation, the two shafts will experience significant additional relative displacement. In such cases, a flexible coupling should be selected. 4. Reliability of couplings and working environment. Couplings made of metal components and requiring no lubrication are generally more reliable; couplings that require lubrication are subject to performance degradation due to the quality of lubrication, and they may also pollute the environment. 5. Manufacturing, installation, maintenance and cost of the coupling. Under the premise of meeting the operational requirements, a coupling that is easy to disassemble and assemble, simple to maintain, and has a low cost should be selected.

- Quick Links

- About

- Products

- Our Service

- News & Events

- Contact

- Products Series

- Flexible Couplings with Non-Elastic Elements

- Flexible Couplings with Metal Elastic Elements

- Flexible Couplings with Non-Metallic Elastic Elements

- Safety Coupling

- Rigid Coupling

- Contact Us

- Tel : +86 511 8572 3800 +86 511 8572 3900

- Mobile : +86 15106109009

- Email : [email protected]

- Add:No.1 Zhongye Yingbin Avenue, Gaozi Street, Dantu Economic Development Zone, Zhenjiang City, Jiangsu Province, China.

English

English