How to Select the Appropriate Coupling

The model of the coupling is generally selected based on the transmitted torque, rotational speed, allowable deviation, etc.

When choosing a standard coupling, it is necessary to determine it based on the usage requirements and working conditions, such as the bearing capacity, rotational speed, relative displacement of the two shafts, buffering and vibration absorption, as well as the ease of disassembly, maintenance and replacement of the vulnerable drum-shaped tooth couplings. Comprehensive analysis should be conducted to make the determination. When making the selection, the following points can be considered in sequence: the factors to be considered when choosing a coupling.

1. Characteristics of the coupling devices of the prime mover and the working coupling. Depending on the type of the prime mover, the output power and speed vary. Some are stable, while others may have significant impacts or even intense vibrations. This directly affects the selection of the coupling type and is one of the primary bases for selection. For loads that are stable, considering the development trend of the industry, a rigid elastic pin coupling can be chosen; otherwise, a flexible elastic pin coupling or a TL type elastic sleeve pin coupling should be selected.

2. The shaft system connected by the coupling and its operating conditions. For shaft systems with large mass, large rotational inertia, and frequent starting, speed variation, or reversing, it is necessary to consider using an elastic cylindrical pin coupling that can withstand large instantaneous overload and also provide buffering and vibration absorption functions.

3. The rotational speed of the working coupling has an impact on the two-axis connection that requires high-speed operation. In such cases, it is necessary to consider selecting a coupling with a structure featuring high balance accuracy, in order to eliminate the vibration and noise caused by centrifugal force, and to reduce the wear and heat of the related bevel gear coupling, thereby lowering the transmission quality and service life. Among them, the diaphragm coupling has better adaptability to high-speed operation.

Based on the magnitude of the transmitted load, the rotational speed of the shaft, the installation accuracy of the two connected components, and referring to the characteristics of various coupling types, select an appropriate coupling type. When making the specific choice, the following points can be considered:

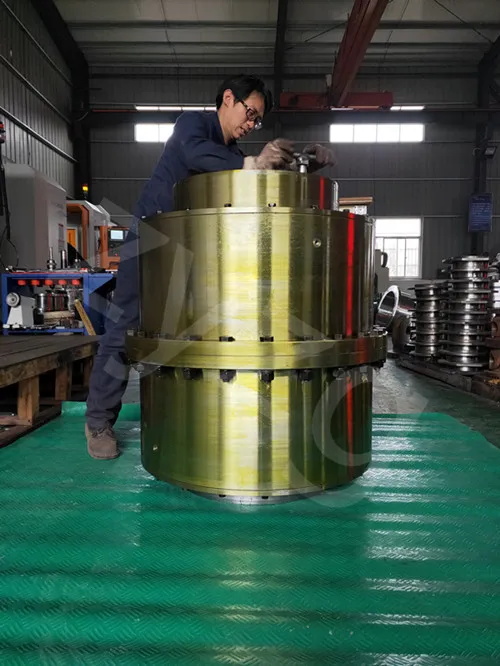

1. The size and nature of the torque to be transmitted, as well as the requirements for buffering and vibration reduction functions. For example, for high-power and heavy-duty transmissions, gear couplings can be selected; for transmissions subject to severe impact loads or those requiring the elimination of shaft system torsional vibrations, elastic couplings such as tire-type couplings can be chosen, which have high elasticity.

2. The rotational speed of the coupling and the magnitude of the centrifugal force it generates. For high-speed transmission shafts, a coupling with high balance accuracy should be selected, such as a diaphragm coupling, rather than a sliding block coupling with eccentricity;

3. The magnitude and direction of the relative displacement between the two shafts. After installation and adjustment, it is difficult to maintain the strict and precise alignment of the two shafts, or during operation, the two shafts will experience significant additional relative displacement. In such cases, a flexible coupling should be selected.

4. Reliability of couplings and working environment. Couplings made of metal components and requiring no lubrication are generally more reliable; couplings that require lubrication are subject to performance degradation due to the quality of lubrication, and they may also pollute the environment.

5. Manufacturing, installation, maintenance and cost of the coupling. Under the premise of meeting the operational requirements, a coupling that is easy to disassemble and assemble, simple to maintain, and has a low cost should be selected.

English

English