How to Locate the Center Point of the Diaphragm Coupling and Analysis of Maintenance Precautions

When the diaphragm coupling operates at high speed, the radial movement caused by centrifugal force leads to accelerated wear and increases the size of the housing. The diaphragm coupling not only prevents dust and oil, but also causes interference if the amount of thinning is insufficient. If it thins out, the strength of the teeth will weaken and the gap on the side will also increase.

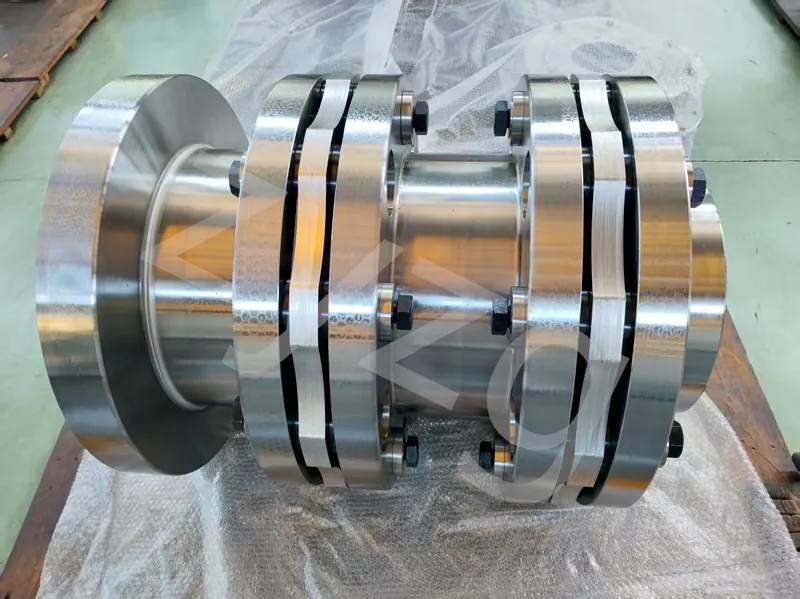

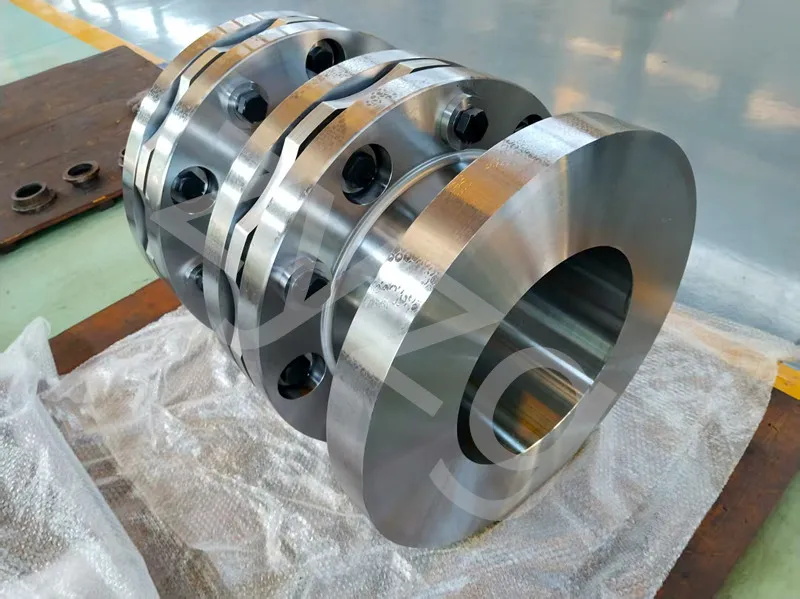

How to find the center point of a diaphragm coupling? According to the principle of measurement, the use of common measuring tools such as feeler gauges, dial indicators, and bridge meters, as well as the consideration of the data recording and calculation process after measurement, and based on the measurement results to create a status diagram, can accurately adjust the coupling and achieve the connection accuracy of the two shafts. The installation of the diaphragm coupling makes the line of one rotor shaft become a continuous curve of the other rotor shaft. Therefore, it is necessary to maintain the matching of the two lines. That is to say, the outer ring surfaces of the two pairs of wheels should be concentric, and the two pairs of mating surfaces should be parallel. Therefore, the center point should be found during the installation of the diaphragm coupling.

The initial selected size of the diaphragm coupling should meet the requirements of the diameters of the main shaft and the driven shaft. Otherwise, the specifications of the diaphragm coupling need to be adjusted according to the diameter of the shaft. When the torque and rotational speed are the same but the diameters of the main shaft and the longitudinal shaft are different, the model can be selected based on the diameter of the main shaft. After choosing the model based on the nominal torque, connection form, shaft hole diameter and length, it is necessary to confirm whether the working speed, relative offset, etc. of the shaft are within the sufficient range of the selected diaphragm coupling, and perform strength checks on the shaft and key connections. In addition, the balance accuracy also needs to be determined.

When designing the overall structure of the diaphragm coupling, attention should be paid to the lubrication, dust prevention and protection effect between the tooth surface and the roller. Because the breakage of the chain can cause personal accidents, and the curvature radius of the bell curve is proportional to the reduction amount of the internal teeth on one side.

The following are the precautions to be noted during the maintenance of the diaphragm coupling:

(1) Basic inspection requirements: The connection must be firm, the connecting bolts and connecting keys must not be loose, and there should be no obvious sensation of radial and end face jumps when the internal diameter and end face are transmitted visually. When using instruments for inspection, it should not be too large.

(2) Gear safety inspection: When the transmission noise increases or during the precise inspection of the product, it should be removed for inspection.

(3) Elasticity inspection: When the rubber ring and leather pad are damaged, they should be replaced as soon as possible. If the pin and the hole are damaged and vibration occurs, a certain angle of rotation of the half-body should be drilled once and a standard new pin should be replaced. The original hole should not be extended onto the new pin.

(4) Problems such as incomplete sealing of the lubricating series oil, oil deterioration, oil leakage and running out. When any of the above situations occur, the oil should be shut off and replaced, and oil shortage should be replenished as soon as possible.

English

English