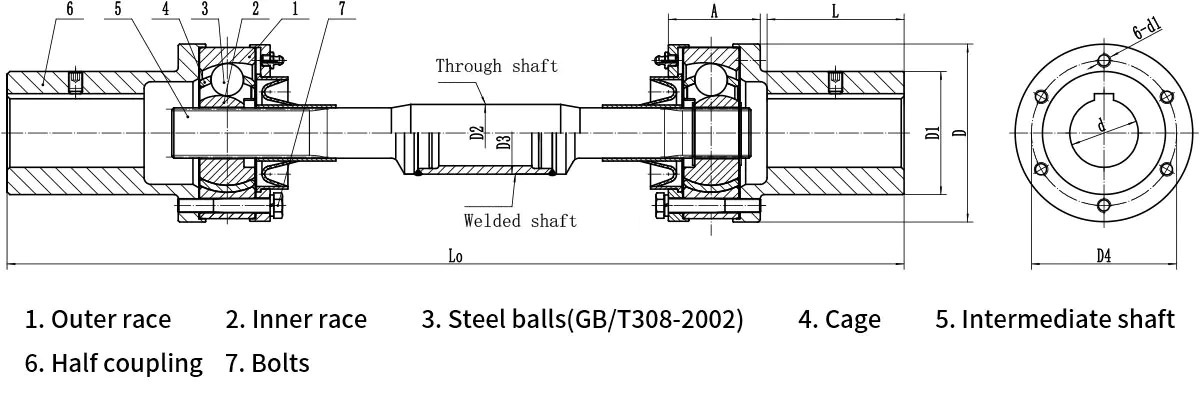

QWL Type Ball Cage Universal Coupling

Core Characteristics and Application Analysis of QWL-type Ball Cage Universal Coupling

The QWL-type ball cage universal coupling is a high-precision transmission component. Its core advantage lies in ensuring the synchronous transmission of two shafts. Even when there is an axial angle or slight radial and axial displacement between the two shafts, it can still achieve constant-speed rotation. This is also the key feature that distinguishes it from ordinary cross-shaft universal couplings.

1. Core Technical Parameters

Nominal Torque Range: 180–10000 N·m, which meets the torque requirements of medium and heavy-duty transmission scenarios.

Rotary Diameter: 85–275 mm. The rotary diameter determines the installation space limit of the coupling, and it is necessary to match the radial installation dimensions of the equipment during model selection.

Maximum Axis Angle: β≤14°–18°. The upper limit of the axis angle varies slightly among different specifications of QWL couplings. In actual use, the axis angle should be controlled within the rated range to avoid the reduction of torque transmission efficiency and the aggravation of component wear.

2. Principle of Synchronous Transmission

The core of the ball cage structure is that the steel balls roll purely in the windows of the ball cage as well as the inner and outer raceways. The centers of the inner and outer raceways coincide with the center of the coupling. This ensures that when there is an angle between the axes, the transmission trajectory of the steel balls remains symmetrical at all times, thereby realizing the complete consistency of the angular velocities of the input shaft and the output shaft and meeting the requirements of synchronous transmission.

3. Application Scenarios

Due to its characteristics of synchronism, stable transmission and impact resistance, it is widely used in equipment with high requirements for transmission accuracy, including:

- Metallurgical machinery (e.g., roller table transmission of rolling mills)

- Heavy mining equipment

- High-precision conveyor lines

- Construction machinery (e.g., slewing mechanism of cranes)

- Spindle drive system of CNC machine tools

4. Notes on Model Selection

Check the actual transmitted torque and reserve a safety factor of 1.2–1.5 times to avoid overload damage.

Confirm the axis angle between the two shafts, which must not exceed the rated upper limit of the coupling of this specification.

Match the rotary diameter of the installation space, and take into account the connection form of the shaft ends (such as key connection, expansion sleeve connection, etc.).

If the working environment contains dust or corrosive media, a corresponding sealing and protective structure should be selected.

- Product Parameters

- Send Message

Zhongye Heavy Industry Technology (Zhenjiang) Co., Ltd. is located in a well-known ancient city, Zhenjiang. We are an enterprise integrating R & D, manufacturing, and sales. Our products are widely used in metallurgical equipment, mining equipment, water equipment, lifting equipment, paper equipment, port equipment and other industries.

Our main products are toothed coupling, elastic sleeve column pin coupling, elastic column pin coupling, gear coupling with elastic pin, a universal coupling, tire coupling, jaw coupling, star coupling, diaphragm coupling, drum coupling and grid coupling, the Oldham coupling, flange coupling, clip shell coupling, GL type roller chain coupling and a safety coupling, and so on. Our company also undertakes a variety of non - standard coupling designs and manufacturing.

New workshop covers an area of about 16463.52 m². heavy workshop 5,500 M2, Precision workshop 4,600 m² , office building and the gymnasium 2000 M2, Dinning hall 500m² , Warehouse 1000 m², Roads, greening, parking areas 3563 M2.

English

English