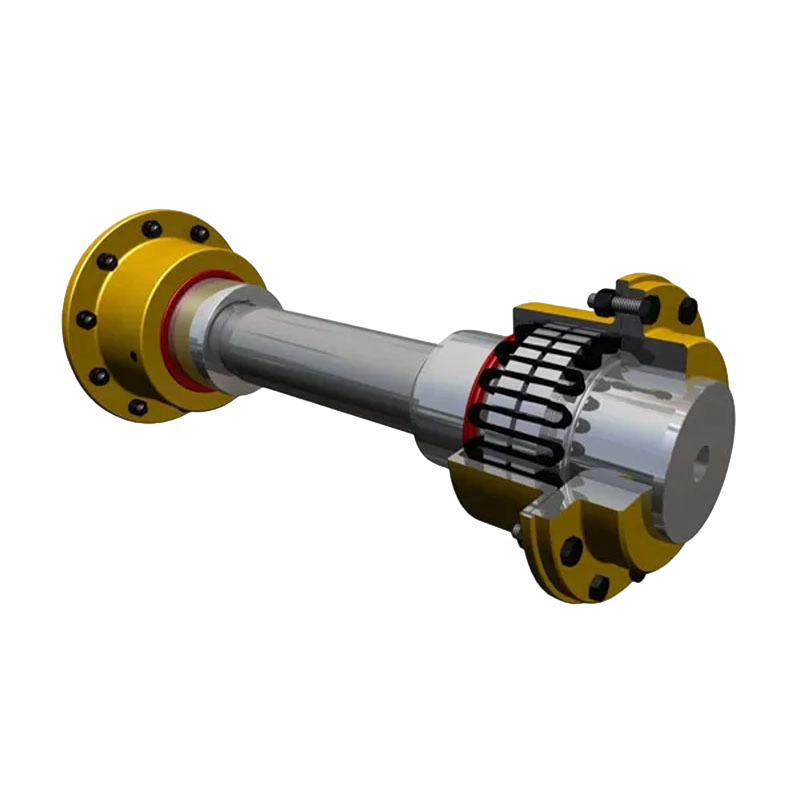

Introduction: The SWC-WF Type Large Size Universal Coupling without Expansion Flange is an...

Products

Products

Don't hesitate to send a message

+86 511 8572 3900

+86 15106109009 Keep in touch

Products

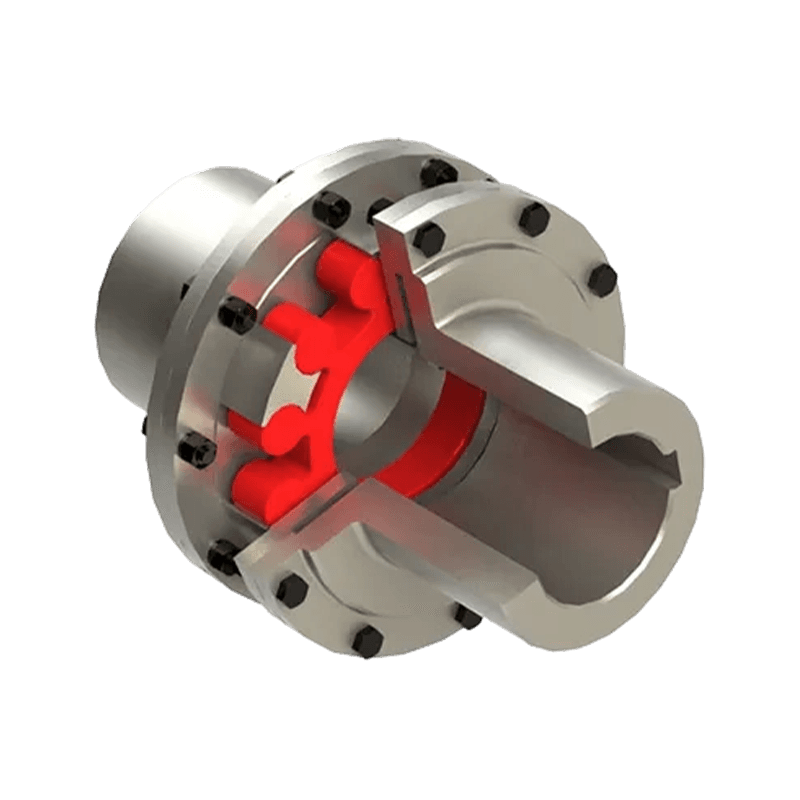

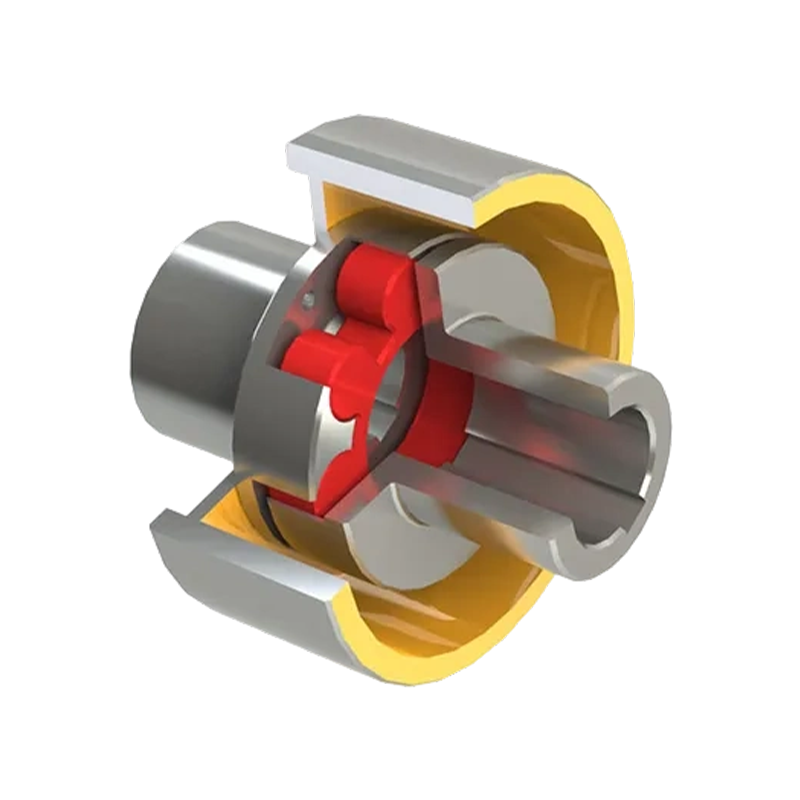

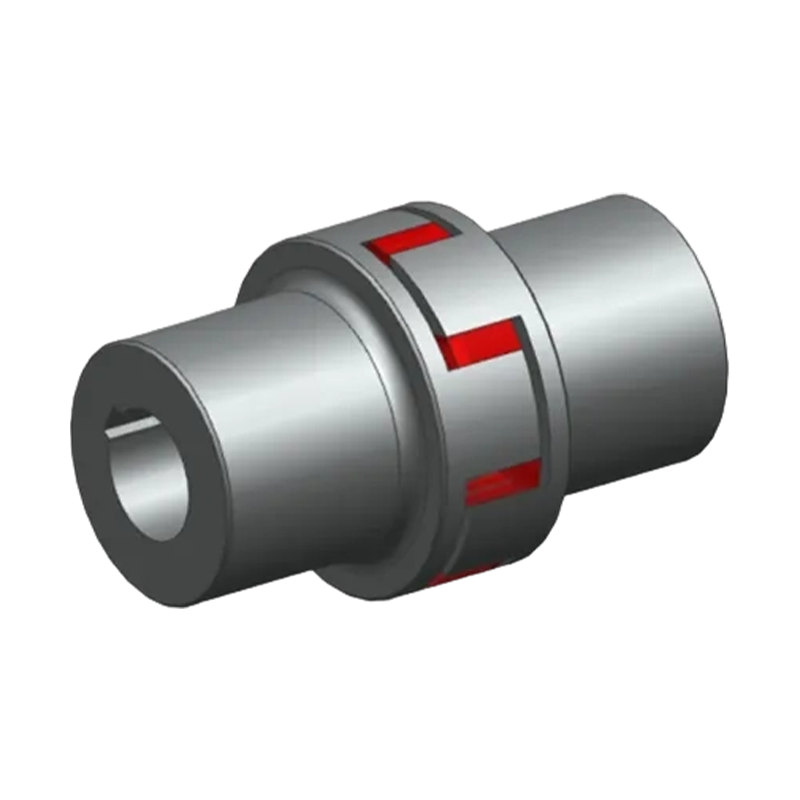

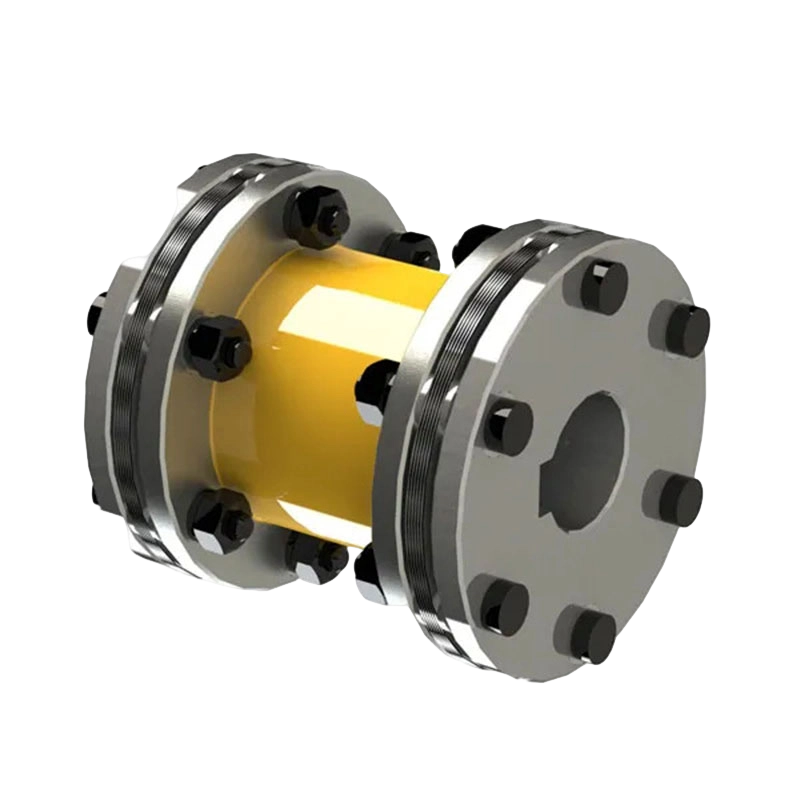

Our main products are toothed coupling, elastic sleeve column pin coupling, elastic column pin coupling, gear coupling with elastic pin, a universal coupling, tire coupling, jaw coupling, star coupling, diaphragm coupling, drum coupling and grid coupling, the Oldham coupling, flange coupling, clip shell coupling, GL type roller chain coupling and a safety coupling, and so on.

-

-

SWC-CH type long expansion welding universal coupling

SWC-CH type long expansion welding universal couplingIntroduction: The SWC-CH Type Long Expansion Welding Universal Coupling embodies a sophist...

-

SWC-WD non-telescopic short universal coupling

SWC-WD non-telescopic short universal couplingIntroduction: The SWC-WD Non-Telescopic Short Universal Coupling is a precision-engineered...

-

QWL Type Ball Cage Universal Coupling

QWL Type Ball Cage Universal CouplingCore Characteristics and Application Analysis of QWL-type Ball Cage Universal CouplingThe ...

-

JMJ Double Half Reverse Diaphragm Coupling

JMJ Double Half Reverse Diaphragm CouplingIntroduction: The JMJ Double Half Reverse Diaphragm Coupling represents a pinnacle in prec...

-

JMJ single half reverse diaphragm coupling

JMJ single half reverse diaphragm couplingIntroduction: The JMJ Single Half Reverse Diaphragm Coupling stands as a robust and innova...

-

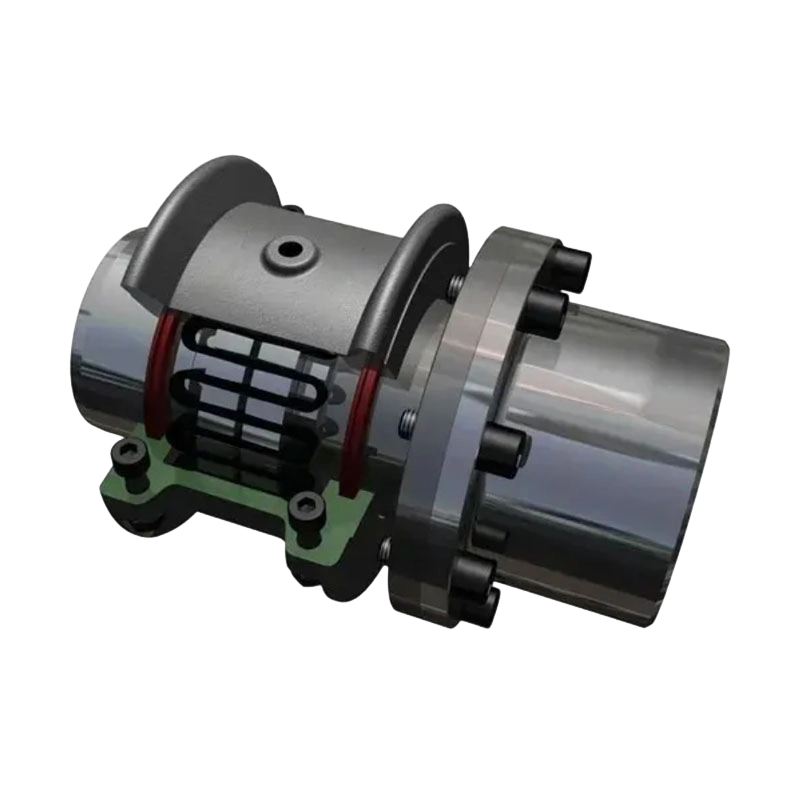

T90 snake spring coupling with clutch

T90 snake spring coupling with clutchThe T90 Snake Spring Coupling with Clutch is a state-of-the-art mechanical coupling system...

-

T70 snake spring coupling with connect shaft

T70 snake spring coupling with connect shaftThe T70 Snake Spring Coupling is a highly advanced and versatile mechanical component desi...

-

T63 snake spring coupling with brajke disc

T63 snake spring coupling with brajke discOverview: The T63 Snake Spring Coupling with Brake Disc is a cutting-edge engineering marv...

-

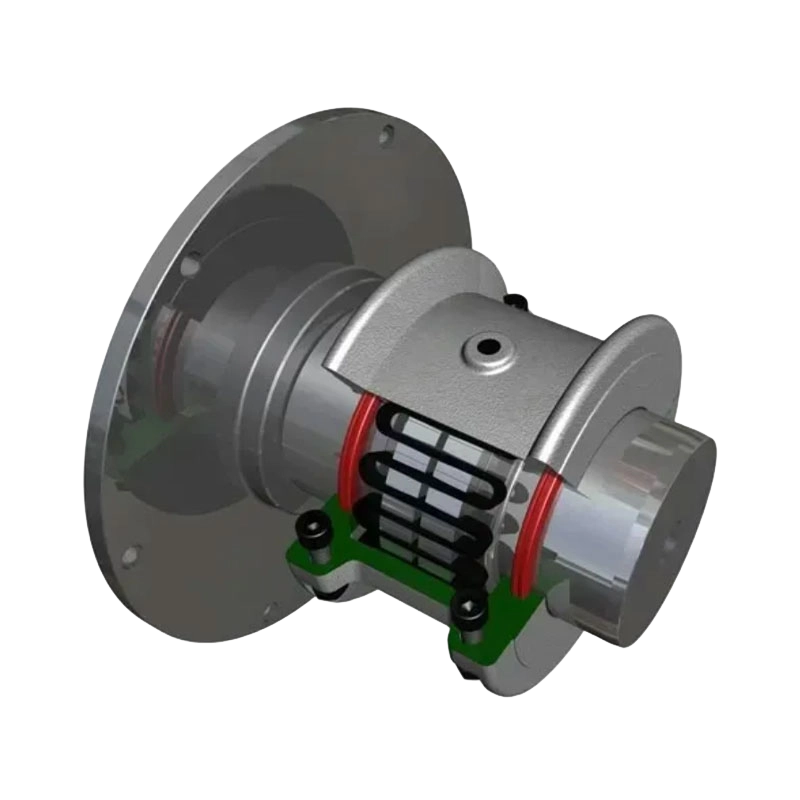

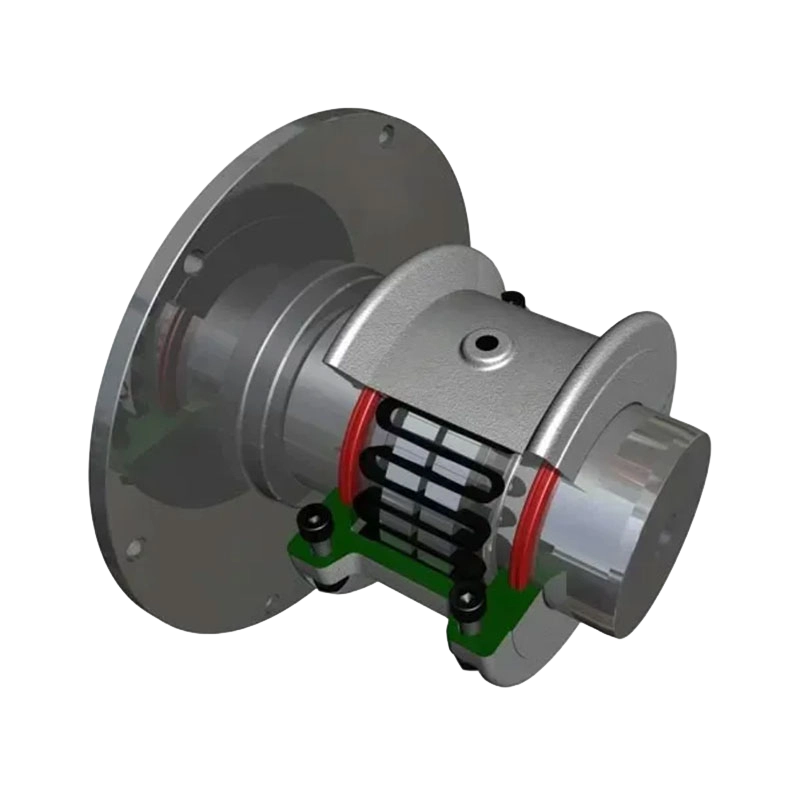

T35 single flange type snake spring coupling

T35 single flange type snake spring couplingOverview The T35 Single Flange Type Snake Spring Coupling is a versatile and robust flexib...

-

T50 snake spring coupling with connect shaft

T50 snake spring coupling with connect shaftA snake spring coupling with a connecting shaft is a mechanical device used in power trans...

-

SWC-WH type non-expansion welded universal coupling

SWC-WH type non-expansion welded universal couplingIntroduction: The SWC-WH Type Non-Expansion Welded Universal Coupling represents a versati...

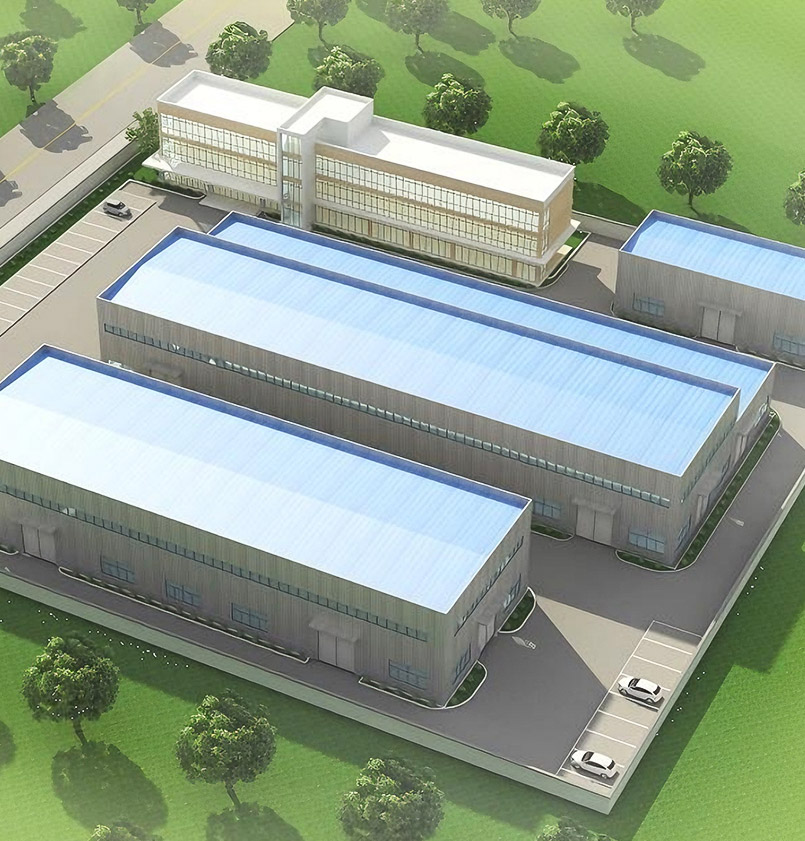

Zhongye Heavy Industry Technology (Zhenjiang) Co., Ltd. is located in a well-known ancient city, Zhenjiang. We are an enterprise integrating R & D, manufacturing, and sales. Our products are widely used in metallurgical equipment, mining equipment, water equipment, lifting equipment, paper equipment, port equipment and other industries.

Our main products are toothed coupling, elastic sleeve column pin coupling, elastic column pin coupling, gear coupling with elastic pin, a universal coupling, tire coupling, jaw coupling, star coupling, diaphragm coupling, drum coupling and grid coupling, the Oldham coupling, flange coupling, clip shell coupling, GL type roller chain coupling and a safety coupling, and so on. Our company also undertakes a variety of non - standard coupling designs and manufacturing.

New workshop covers an area of about 16463.52 m². heavy workshop 5,500 M2, Precision workshop 4,600 m² , office building and the gymnasium 2000 M2, Dinning hall 500m² , Warehouse 1000 m², Roads, greening, parking areas 3563 M2.

-

2025.06.20The operation status of each component of the couplingCoupling alignment is to approximately regard the projection of the motor's movable end face circle on the fixed end face as a perfect circle, and the distance from the center of the movable end to the fixed end face remains unchanged. The axis of the movable end and the axis of the fixed end are on the same line. In actual alignment, an allowable error is set. When the error generated during alignment is within the allowable error range, it indicates that the alignment is complete. In many cases, the lower detection point of the coupling cannot be detected, and the alignment work cannot be carried out. The connection of the coupling must be firm. The connection bolts and keys must not be loose. Radial and end face runout of the coupling during operation. When the coupling bolt holes are severely worn, the mechanism will vibrate during operation, and even the bolts may break. If the bolt holes are severely worn and cannot be repaired, the coupling should be scrapped. Damaged rubber pads of the coupling should be replaced in time. If they are squeezed and damaged, vibration will occur. The half-body should be rotated at an angle and re-drilled. For couplings with lubrication devices, check whether the oil seal is intact, whether the lubricating oil has deteriorated, and whether there is oil leakage. If they are misused or not installed correctly during use, they are prone to damage. Ensure that the deviation is within the normal operating range of the coupling. During operation, frequently check whether the coupling has any abnormal phenomena. If any abnormal phenomena occur, repair them promptly. To prevent fretting wear caused by high-speed operation, which may lead to micro-cracks in the bolt holes and damage. The couplings themselves also have a certain degree of metal elasticity. And in the actual transmission process, they have a large torque structure. Compared with the couplings themselves, they are very compact and can accurately transmit speed. When the torque reaches the range that the coupling cannot withstand, the elastic body will have problems. At this time, it will give a warning to avoid damage to the equipment.

-

2025.06.13GCT Intermediate Sleeve Drum Gear Coupling: Enhancing Reliability in Industrial Power TransmissionTo meet the growing demand for high-performance coupling solutions across heavy-duty industries, [Your Company Name] proudly introduces the GCT Intermediate Sleeve Drum Gear Coupling — a product engineered to deliver exceptional torque transmission, durability, and adaptability in the most demanding environments. The GCT coupling features an innovative intermediate sleeve drum design, allowing it to efficiently compensate for shaft misalignments while minimizing stress and wear on connected equipment. This unique structure ensures smooth and reliable power transfer, making it ideal for applications where rotational accuracy and mechanical stability are critical. Manufactured from high-grade, wear-resistant materials, the GCT coupling withstands harsh industrial conditions including high temperatures, corrosive atmospheres, and heavy loads. It’s suitable for integration with conveyors, pumps, compressors, and a variety of other rotating machinery. Key advantages include: Enhanced Misalignment Compensation Robust Construction and Long Service Life Precision Torque Transmission with Minimal Backlash Easy Installation and Low Maintenance Wide Compatibility Across Industrial Applications The coupling’s versatility makes it a preferred choice in industries such as manufacturing, mining, power generation, and mechanical engineering, where reliable power transmission is mission-critical. With the GCT Intermediate Sleeve Drum Gear Coupling, [Your Company Name] reinforces its commitment to providing innovative, high-efficiency mechanical solutions for the modern industrial world.

-

2025.05.23The connection parts of universal couplings are not prone to looseningOnce both ends of the universal coupling are installed, it can be put into operation. The connection at the driving end is a tight fit and is not easy to loosen, while the connection at the driving end is often a loose fit and is prone to disengagement after operation. As a result, the efficiency of the universal coupling in transmitting torque is reduced. Universal couplings are equipped with built-in springs to prevent the mating parts from retracting during operation, maintaining a constant fit length and enhancing the stability of transmission. The universal coupling is equipped with a protective sleeve to prevent dust and water from the external environment from entering the interior of the splines when they move relatively, thus prolongs the service life of the spline pair. The centers of the force-transmitting steel balls are all located in the plane passing through the center of the coupling and are installed in the raceway composed of the spherical outer ring and the spherical outer surface groove of the star-shaped inner ring. The centers of the two spherical surfaces coincide with the center of the universal coupling. To ensure that the centers of all steel balls are on the bisector of the Angle between the axes of the two shafts, the steel balls are installed in a ball cage. This guarantees that when the Angle between the driving and driven shafts of the coupling changes, the force transmission point can always be on the bisector of the Angle, and the transmission speeds between the driving and driven shafts can be kept synchronized. The transmission mode of universal couplings can adopt sliding transmission or rolling transmission. When sliding transmission is used, in order to buffer and reduce vibration, polymer buffer sleeves are installed on the ball arm and the force transmission arm. When rolling transmission is adopted, the original buffer sleeves on the ball arm and the force transmission arm are modified into rolling elements. Meanwhile, the original buffer pads between the ball head and the socket seat are also changed into rolling elements to meet the requirements of rigid transmission. The force transmission arm pair includes a ball arm and a force transmission arm. The force transmission arm is installed in the hole or groove of one connection plate with bolts, and the ball arm is installed in the hole or groove of the other connection plate. It has the performance of buffering and vibration reduction, can reduce noise, and automatically lubricate in a cycle.

-

2025.05.23The positioning wear condition of the drum couplingWhen the relative displacement between the positioning wear indicator and the positioning wear mark exceeds the specified value, it indicates that the wear has reached a certain thickness and the coupling should be replaced promptly. When the drum is subjected to both forward and reverse loads during operation, the relative displacement between the positioning wear indicator and the positioning wear mark; for the drum coupling to maintain dynamic balance, the key should be precisely inserted into the keyway and should not be too short or too long. The semi-flexible coupling is heated in an oil tank or an oven. The heating temperature depends on the interference amount. When there is a relative offset between the two shafts, the elastic element undergoes corresponding elastic deformation, thus playing an automatic compensation role. For bolts that are rusted or have a lot of oil deposits, solvent is often sprayed onto the connection between the bolt and the nut to allow the solvent to penetrate the threads. This makes disassembly easier. The new bolts are of the same specification as the original ones and are used for the newly replaced bolts of the coupling in high-speed equipment. This ensures that the weight of the new bolts is the same as that of the connecting bolts on the same group of flanges. During assembly, the new bolts are replaced. The coupling mainly consists of two parts with protruding teeth that closely mesh and bear radial compression to transmit torque. The sliding block coupling, on the other hand, transmits through shear force. It is difficult for us to achieve this by changing the moment of inertia, but the stiffness of the shaft system can be easily changed. The coupling is designed to change the stiffness of the shaft system in order to avoid resonance. The bearing seat undergoes displacement due to long-term vibration. Since vibration generated by large fans is inevitable, this can easily cause slight loosening of the fastening bolts on the base, and the consequence is unbalanced rotation and vibration.

-

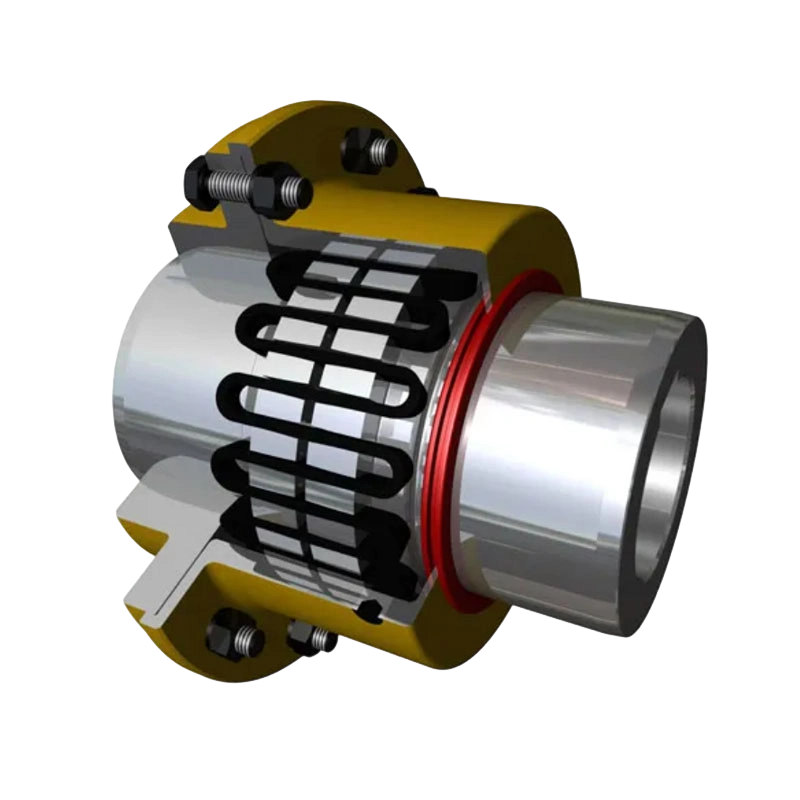

2025.05.16T31 Double Flange Snake Spring Coupling – A New Benchmark in Efficient Power TransmissionTo meet the growing industrial demand for high reliability, durability, and low maintenance, we are proud to introduce the T31 Snake Spring Coupling with Double Flange—a high-performance flexible coupling engineered to deliver smooth, efficient torque transmission while accommodating shaft misalignment. High Performance · Flexible Alignment · Low Maintenance The T31 coupling features a unique snake spring design that effectively absorbs shock and vibration, making it ideal for handling angular, radial, and axial misalignments. Its double flange construction enhances connection stability between shafts, ensuring reliable torque transfer even under demanding conditions. Whether in heavy-duty start-ups, frequent stop-and-go operations, or harsh environments, the T31 stands out for its exceptional durability. Versatile Applications · Trusted Solution The T31 Snake Spring Coupling is widely applicable in pumps, fans, compressors, conveyors, and other industrial machinery—especially where long service life and consistent performance are essential. Its simple structure reduces maintenance time and costs, making it a smart choice for businesses focused on efficiency and cost-effectiveness. At the core of our innovation is a commitment to smarter, more reliable coupling solutions. The T31 Double Flange Snake Spring Coupling is not just a product upgrade—it’s a reflection of our dedication to quality and performance. For more information, feel free to contact us today!

-

2025.04.26Couplings in Action: Exploring the Wide-Ranging Applications Across IndustriesCouplings, though often small in size, play an outsized role in powering the world’s most critical industries. By connecting two shafts together, couplings enable the efficient transfer of torque and rotation—making them indispensable across a broad spectrum of industrial applications. In the automotive industry, couplings are found in drive systems and test rigs, helping manufacturers ensure precision and performance in both production lines and vehicle systems. Their ability to handle misalignment and absorb shock makes them essential for high-speed operations. In power generation, couplings are used to link turbines, generators, and pumps. Whether in fossil fuel plants or renewable energy setups like wind and hydroelectric systems, couplings ensure the safe and stable transfer of energy under extreme conditions. Mining and heavy machinery rely on robust, high-torque couplings to operate conveyor belts, crushers, and drilling systems. These environments demand durability, resistance to contamination, and the ability to handle large angular misalignments. The marine sector also benefits from flexible couplings in propulsion systems, helping ships navigate smoothly by reducing vibration and compensating for shaft misalignment due to rough sea conditions. In the food and beverage industry, hygienic and corrosion-resistant couplings help drive mixers, pumps, and packaging equipment—meeting strict cleanliness standards while maintaining performance. Additionally, automation and robotics require lightweight, high-precision couplings that support fast, accurate movements. These are critical for achieving tight tolerances in electronic manufacturing, assembly lines, and more. With such a wide range of use cases, couplings remain a vital component behind the scenes—quietly enabling power transmission, protecting machinery, and ensuring smooth operations across industries worldwide. Would you like to add a specific product reference or highlight your company’s solutions in these industries?

- Quick Links

- About

- Products

- Our Service

- News & Events

- Contact

- Products Series

- Flexible Couplings with Non-Elastic Elements

- Flexible Couplings with Metal Elastic Elements

- Flexible Couplings with Non-Metallic Elastic Elements

- Safety Coupling

- Rigid Coupling

- Contact Us

- Tel : +86 511 8572 3800 +86 511 8572 3900

- Mobile : +86 15106109009

- Email : [email protected]

- Add:No.1 Zhongye Yingbin Avenue, Gaozi Street, Dantu Economic Development Zone, Zhenjiang City, Jiangsu Province, China.

English

English