JMJ single half reverse diaphragm coupling

Introduction: The JMJ Single Half Reverse Diaphragm Coupling stands as a robust and innovative solution in the realm of mechanical power transmission systems. Designed with precision engineering and advanced materials, this coupling offers unparalleled performance and reliability, making it an ideal choice for various industrial applications.

Key Features:

- Single Half Design: The JMJ coupling features a unique single-half design, enhancing its flexibility and ease of installation. This innovative approach reduces complexity while maintaining the coupling's efficiency and durability.

- Reverse Diaphragm Configuration: The reverse diaphragm configuration is a standout feature that ensures optimal torque transmission and compensates for misalignments between shafts. This design minimizes stress concentrations, resulting in extended coupling life and improved overall system performance.

- High-Quality Materials: Crafted from high-quality materials such as stainless steel or alloy steel, the JMJ coupling guarantees exceptional strength, corrosion resistance, and durability. This ensures reliable operation even in challenging industrial environments.

- Precision Machining: Every component of the JMJ coupling undergoes precision machining, maintaining tight tolerances and ensuring the highest level of performance. The attention to detail in manufacturing contributes to reduced wear and tear, enhancing the coupling's longevity.

- Torque and Misalignment Capacity: With a carefully calculated torque capacity and the ability to accommodate misalignments, the JMJ Single Half Reverse Diaphragm Coupling excels in transmitting power efficiently while compensating for shaft misalignments. This makes it suitable for a wide range of applications in various industries.

- Easy Maintenance: The simple and efficient design of the coupling facilitates easy maintenance and replacement of parts when necessary. This minimizes downtime, contributing to increased productivity and cost-effectiveness for end-users.

Applications:

The versatility of the JMJ Single Half Reverse Diaphragm Coupling makes it suitable for a diverse range of applications, including:

- Industrial Machinery: Ideal for use in various types of industrial machinery, such as pumps, compressors, and conveyors.

- Power Generation: Well-suited for power generation equipment, including generators and turbines.

- Material Handling Systems: Ensures reliable performance in material handling systems, such as cranes and conveyor systems.

- Mining and Minerals Processing: With its robust design, the coupling is suitable for challenging environments in mining and minerals processing equipment.

Conclusion:

In summary, the JMJ Single Half Reverse Diaphragm Coupling is a cutting-edge solution for reliable power transmission in diverse industrial settings. Its innovative design, high-quality materials, and precision engineering combine to deliver a coupling that excels in performance, durability, and ease of maintenance. Whether in heavy machinery, power generation, or material handling, the JMJ coupling stands as a dependable choice for optimizing operational efficiency and minimizing downtime.

- Product Parameters

- Send Message

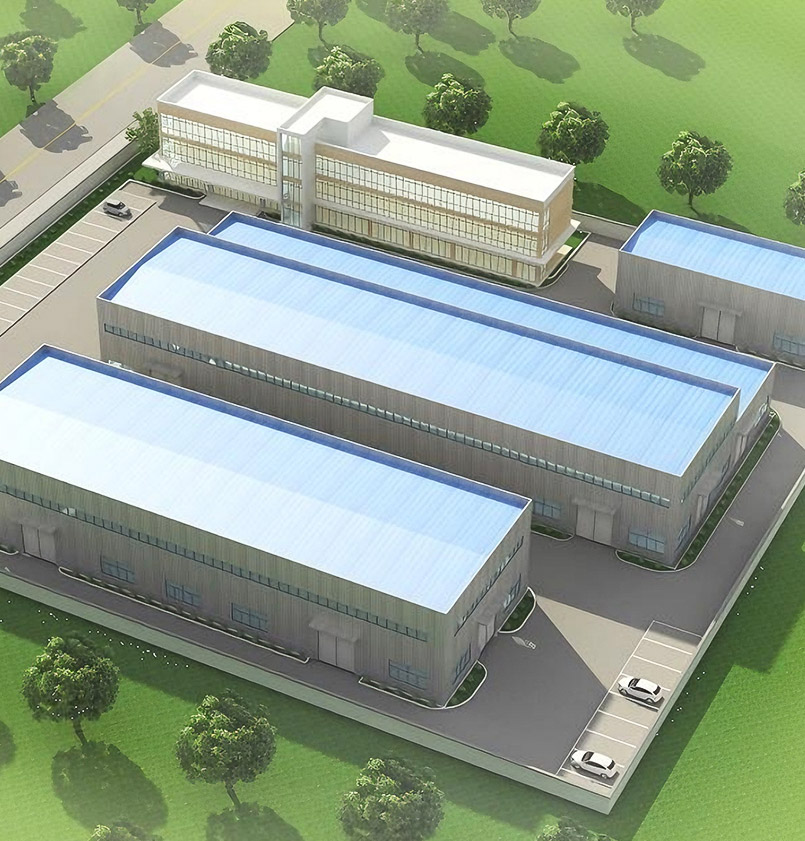

Zhongye Heavy Industry Technology (Zhenjiang) Co., Ltd. is located in a well-known ancient city, Zhenjiang. We are an enterprise integrating R & D, manufacturing, and sales. Our products are widely used in metallurgical equipment, mining equipment, water equipment, lifting equipment, paper equipment, port equipment and other industries.

Our main products are toothed coupling, elastic sleeve column pin coupling, elastic column pin coupling, gear coupling with elastic pin, a universal coupling, tire coupling, jaw coupling, star coupling, diaphragm coupling, drum coupling and grid coupling, the Oldham coupling, flange coupling, clip shell coupling, GL type roller chain coupling and a safety coupling, and so on. Our company also undertakes a variety of non - standard coupling designs and manufacturing.

New workshop covers an area of about 16463.52 m². heavy workshop 5,500 M2, Precision workshop 4,600 m² , office building and the gymnasium 2000 M2, Dinning hall 500m² , Warehouse 1000 m², Roads, greening, parking areas 3563 M2.

English

English