Coupling Technology Innovations Drive Industrial Automation Progress

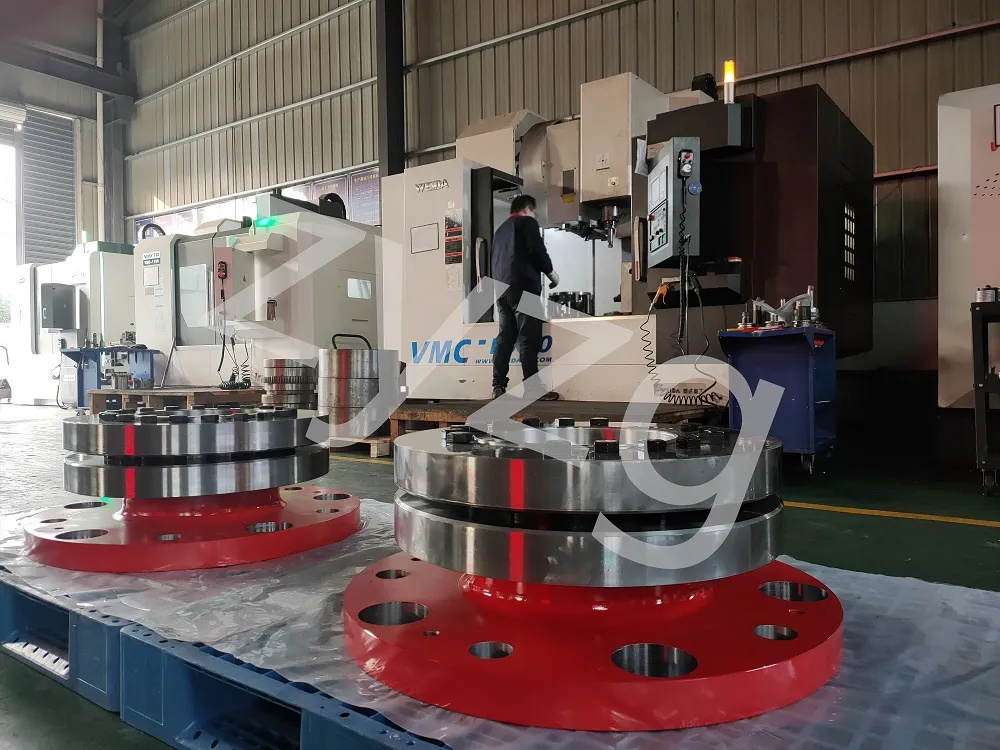

In recent years, coupling technology has rapidly evolved alongside the advancements in industrial automation and smart manufacturing. As a crucial component in mechanical transmission systems, couplings connect two shafts and transmit torque, directly influencing the efficiency and stability of the entire system.

Market Demand Fuels Technological Advancements

With the widespread adoption of Industry 4.0, the manufacturing sector's demand for high-precision and high-efficiency transmission systems is increasing. Traditional rigid couplings are gradually being replaced by more flexible and adaptive products. For instance, elastic couplings and diaphragm couplings have become the market's preferred choices due to their excellent misalignment compensation and high torque transmission capabilities.

Innovations in Materials and Design

In terms of materials, the use of advanced composite materials has enabled significant improvements in the performance of couplings. These materials offer a better balance between strength and flexibility, contributing to longer service life and improved reliability in demanding applications.

Conclusion

As the industrial landscape continues to evolve, the role of couplings in enhancing the efficiency and reliability of mechanical systems will only grow in importance. Companies investing in the latest coupling technologies are poised to lead the way in the next wave of industrial automation.

English

English