The Importance of Couplings in Modern Industry

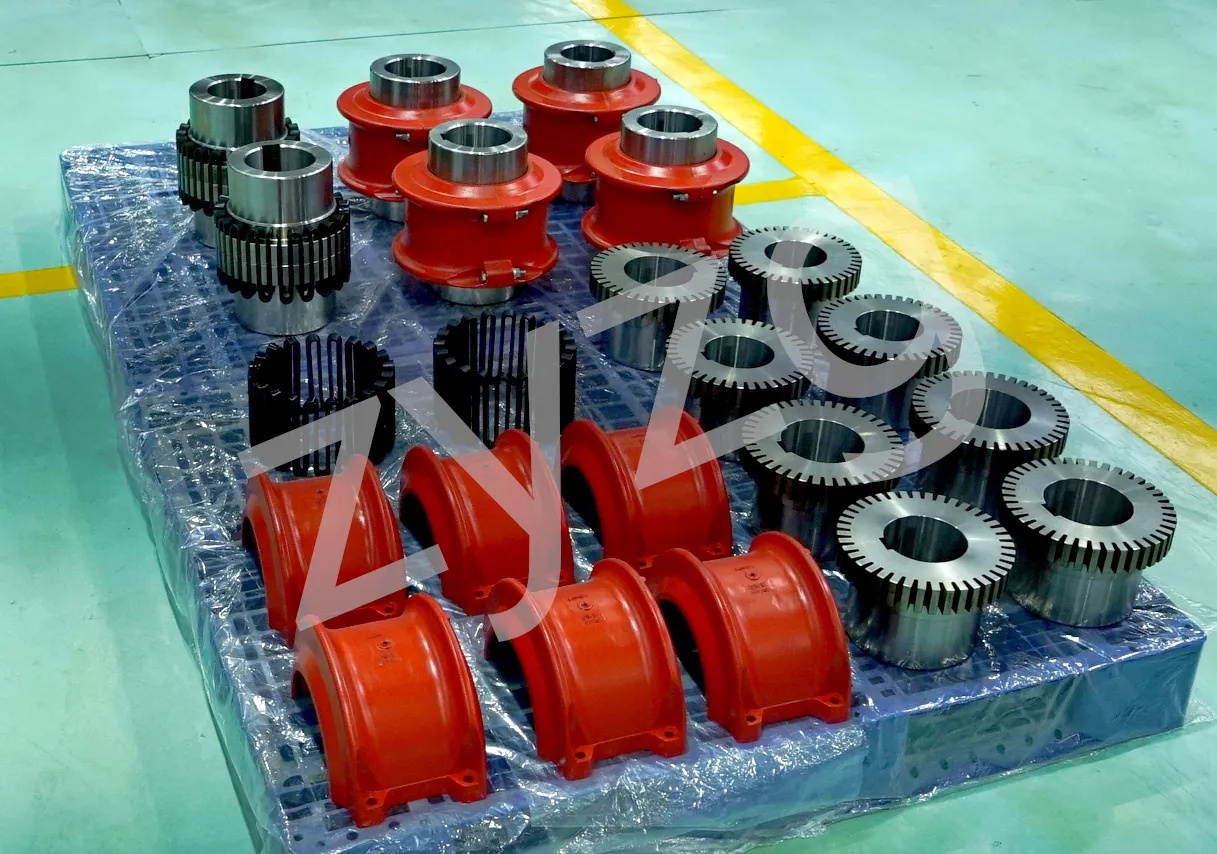

Couplings play a critical role in a wide range of industries, from manufacturing and automotive to power generation and transportation. As mechanical components used to connect two rotating shafts, couplings are essential for transmitting power, compensating for misalignments, and dampening vibrations, thereby protecting machinery and ensuring efficient operation.

Ensuring Reliability and Efficiency

In manufacturing environments, couplings are pivotal in maintaining the integrity of mechanical systems. They provide flexibility that accommodates misalignments, which can occur due to thermal expansion, wear and tear, or inaccuracies in assembly. This not only extends the lifespan of machinery but also reduces downtime, as equipment can continue to operate smoothly without frequent adjustments.

For instance, elastomer jaw couplings are commonly used in conveyor systems to absorb shocks and vibrations, minimizing wear on connected components. Steel disc couplings, on the other hand, offer high torsional stiffness and are preferred in precision applications where maintaining positional accuracy is crucial, such as in robotics and CNC machinery.

Safety and Maintenance Benefits

Couplings also enhance safety by absorbing impacts and vibrations, which can otherwise lead to mechanical failure or hazardous conditions. Locking assemblies and friction springs, as highlighted at recent industry exhibitions, demonstrate how modern coupling designs focus on high reliability and zero-maintenance solutions. These innovations are crucial in high-stress environments like rolling mills, where the performance and safety of equipment are non-negotiable.

Driving Technological Advances

The integration of advanced materials and digital technologies is pushing the boundaries of what couplings can achieve. Innovations like Digital Automatic Coupling (DAC) in the rail industry highlight the transformative potential of couplings in enhancing automation and efficiency. By enabling automatic connection and disconnection of wagons, DAC systems significantly reduce manual labor, enhance operational speed, and contribute to sustainability efforts by making rail freight more competitive with road transport.

Conclusion

The importance of couplings extends beyond their basic mechanical functions. They are integral to the efficiency, safety, and longevity of countless industrial systems. As industries continue to evolve and demand higher performance standards, the role of couplings is set to become even more crucial, with ongoing innovations promising to unlock new levels of operational excellence and sustainability.

English

English