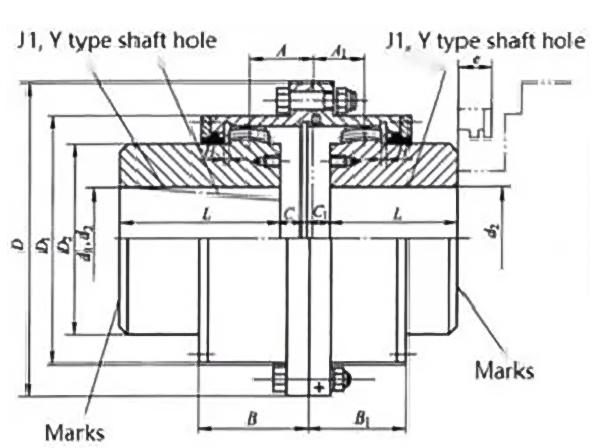

GBD Motor shaft extension drum gear coupling(Q/YG 11003X-2018)

The GBD type motor shaft extension drum gear coupling stands as a stalwart in the realm of power transmission solutions, renowned for its robust design, reliability, and versatility across various industrial applications. Serving as a vital link between motor shafts and driven equipment, the GBD coupling plays a pivotal role in ensuring seamless torque transmission and rotational motion within machinery systems.

Crafted with precision-engineered components, the GBD coupling is engineered to withstand high loads, harsh operating conditions, and dynamic stresses encountered in industrial environments. Its rugged construction, coupled with advanced materials and manufacturing techniques, imbues it with exceptional durability and longevity, making it a preferred choice for demanding applications.

At the heart of the GBD coupling lies its motor shaft extension drum gear mechanism, meticulously designed to facilitate smooth power transmission and mitigate issues such as misalignment, vibration, and shock loads. This gear coupling design ensures precise alignment between the motor shaft and driven equipment, minimizing wear and tear on machinery components and optimizing overall system efficiency.

One of the hallmark features of the GBD coupling is its ability to accommodate angular, parallel, and axial misalignments between shafts, thereby enhancing operational flexibility and reducing the risk of premature component failure. This capability is crucial in environments where precise alignment may be challenging to maintain consistently, ensuring uninterrupted operation and minimizing downtime.

Installation and maintenance of the GBD coupling are streamlined for convenience, with user-friendly features that simplify assembly, disassembly, and servicing procedures. This not only reduces downtime during maintenance activities but also contributes to the cost-effectiveness and reliability of the entire machinery system.

In summary, the GBD type motor shaft extension drum gear coupling embodies the pinnacle of engineering excellence, reliability, and performance in power transmission technology. With its rugged construction, advanced design features, and unwavering commitment to customer satisfaction, it continues to be the preferred choice for businesses seeking dependable solutions to drive their industrial operations forward.

- Product Parameters

- Send Message

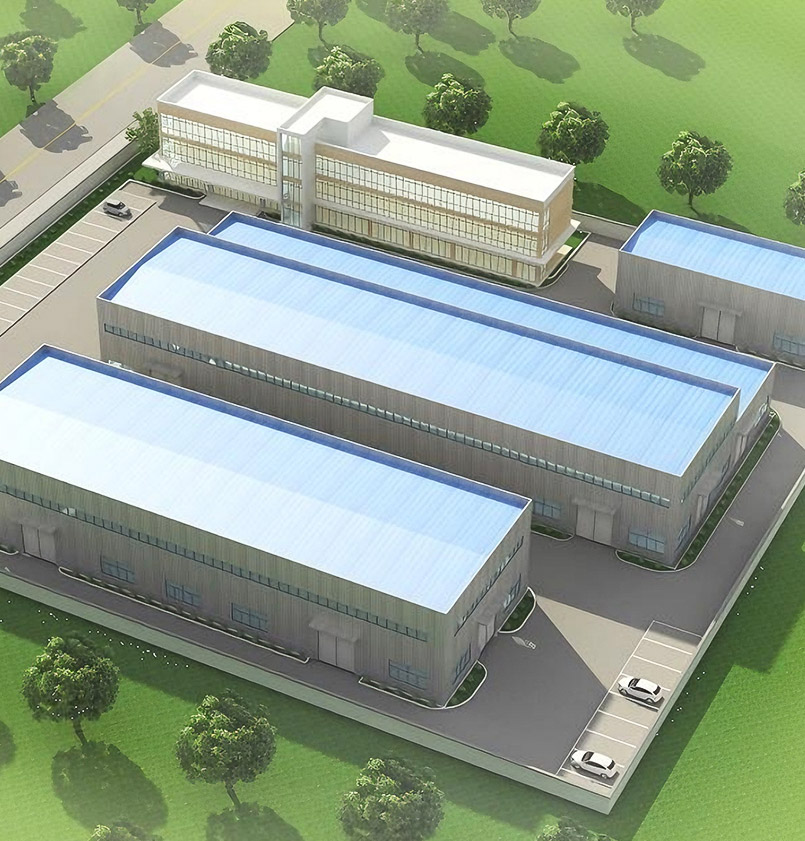

Zhongye Heavy Industry Technology (Zhenjiang) Co., Ltd. is located in a well-known ancient city, Zhenjiang. We are an enterprise integrating R & D, manufacturing, and sales. Our products are widely used in metallurgical equipment, mining equipment, water equipment, lifting equipment, paper equipment, port equipment and other industries.

Our main products are toothed coupling, elastic sleeve column pin coupling, elastic column pin coupling, gear coupling with elastic pin, a universal coupling, tire coupling, jaw coupling, star coupling, diaphragm coupling, drum coupling and grid coupling, the Oldham coupling, flange coupling, clip shell coupling, GL type roller chain coupling and a safety coupling, and so on. Our company also undertakes a variety of non - standard coupling designs and manufacturing.

New workshop covers an area of about 16463.52 m². heavy workshop 5,500 M2, Precision workshop 4,600 m² , office building and the gymnasium 2000 M2, Dinning hall 500m² , Warehouse 1000 m², Roads, greening, parking areas 3563 M2.

English

English