The working principle and application effect of coupling

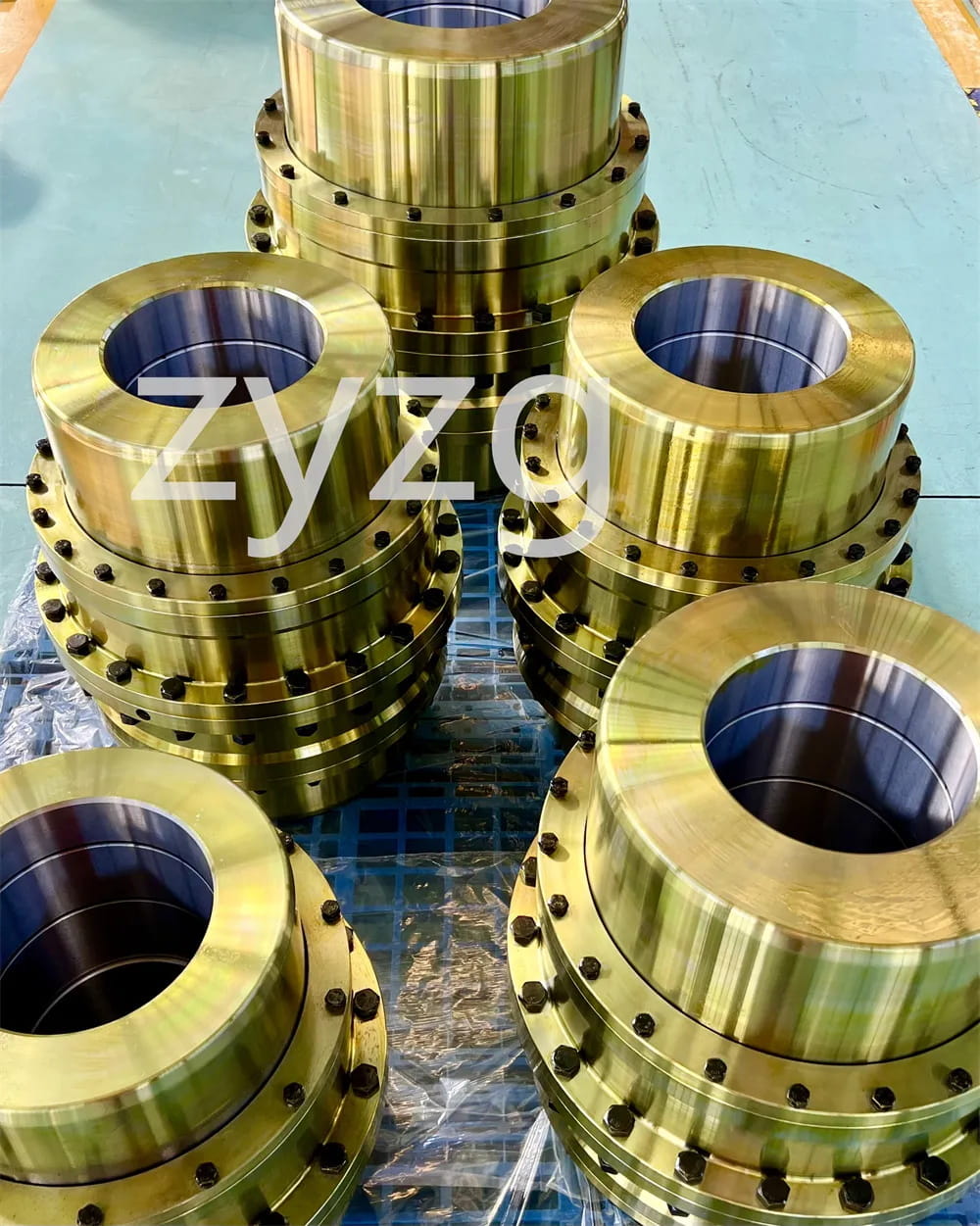

The coupling is used to connect the prime mover shaft and the slave mover shaft of the electromechanical equipment, drive the equipment to run normally, and has a certain ability to compensate the offset of the two axes.

According to the characteristics of the coupling: air bag clutch, hydraulic coupling, centrifugal coupling have overload protection, but the centrifugal coupling and air bag clutch do not have the ability and conditions to absorb the impact load (it has been proved that the centrifugal coupling has caused damage to the equipment), so the hydraulic coupling is selected as the new coupling device of the FP5012 breaker in addition, the coupling also has a slowShock damping performance can reduce the vibration of the mechanical transmission system and reduce the peak impact load.Reasonable selection of coupling of mechanical and electrical equipment is of great significance to improve the reliability and availability of mechanical and electrical equipment in coal mine, reduce the probability of forced outage of equipment, reduce maintenance costs and extend the service life of equipment.

The working principle of the coupling: the rotation of the prime motor drives the swing arm to rotate, and is thrown out under the action of centrifugal force. With the increase of the motor speed, the positive pressure of the 3 centrifugal friction blocks installed on the swing arm on the friction wheel is also increasing, and the friction torque gradually increases and drives the load to operate.Under severe overload or gridlock conditions, the load moment is greater than the friction moment, the centripetal force of the centrifugal friction block is reduced, resulting in the reduction of the sliding block force, and the coupling plays the role of overload protection.When the equipment load suddenly increases or decreases, the friction block and the friction wheel produce intermittent relative motion, resulting in the formation of alternating impact load, repeatedly impacting the coupling output end of the shaft sleeve and the input shaft of the reducer, as the heavy hammer hammer countless times to hit the joint surface, thereby damaging the joint surface, the key pin.In order to effectively improve the operating condition of the equipment, there is a change in the connection device of the electromechanical equipment.

Coupling is an important component of mechanical and electrical equipment, improper selection will affect the operating condition of equipment, and even cause equipment failure.The selection of the coupling must be based on the working performance of the equipment (power, speed, impact, vibration, load change, drag system requirements), the working environment (ambient temperature, ambient humidity) and many other factors, according to the principles of science, rationality, applicability, and economy, choose the coupling applicable to the site, so as to lay a good foundation for the operation of the equipment.Coupling will not appear the output shaft sleeve keyway and key damage phenomenon, equipment operation no noise, no vibration, no impact, all operating indicators are normal, equipment failure rate is significantly reduced.And the large torque value of the coupling is lower than the motor's subversive torque, protecting the motor from overload, if overload or even "stuck" occurs, it can unload itself, thus protecting the motor and transmission mechanism.

English

English