Applications of Couplings Across Various Industries

Couplings are essential mechanical components used to connect two shafts in a variety of industrial applications. Their primary function is to transmit torque and rotation while accommodating misalignment, reducing vibration, and protecting machinery from overloads. Given their versatility and reliability, couplings find extensive use across multiple industries. Here, we explore the diverse applications of couplings in different sectors, highlighting their critical role in ensuring efficient and reliable operations.

1. Manufacturing and Industrial Machinery

In the manufacturing industry, couplings are integral to the operation of a wide range of machinery, including conveyors, mixers, pumps, and compressors. They ensure smooth power transmission between motor-driven systems and their respective machinery, accommodating misalignments that naturally occur due to wear and tear or installation inaccuracies. Flexible couplings, for instance, are widely used in conveyor systems to absorb shock loads and vibrations, thus protecting the mechanical components and ensuring consistent production rates.

2. Power Generation

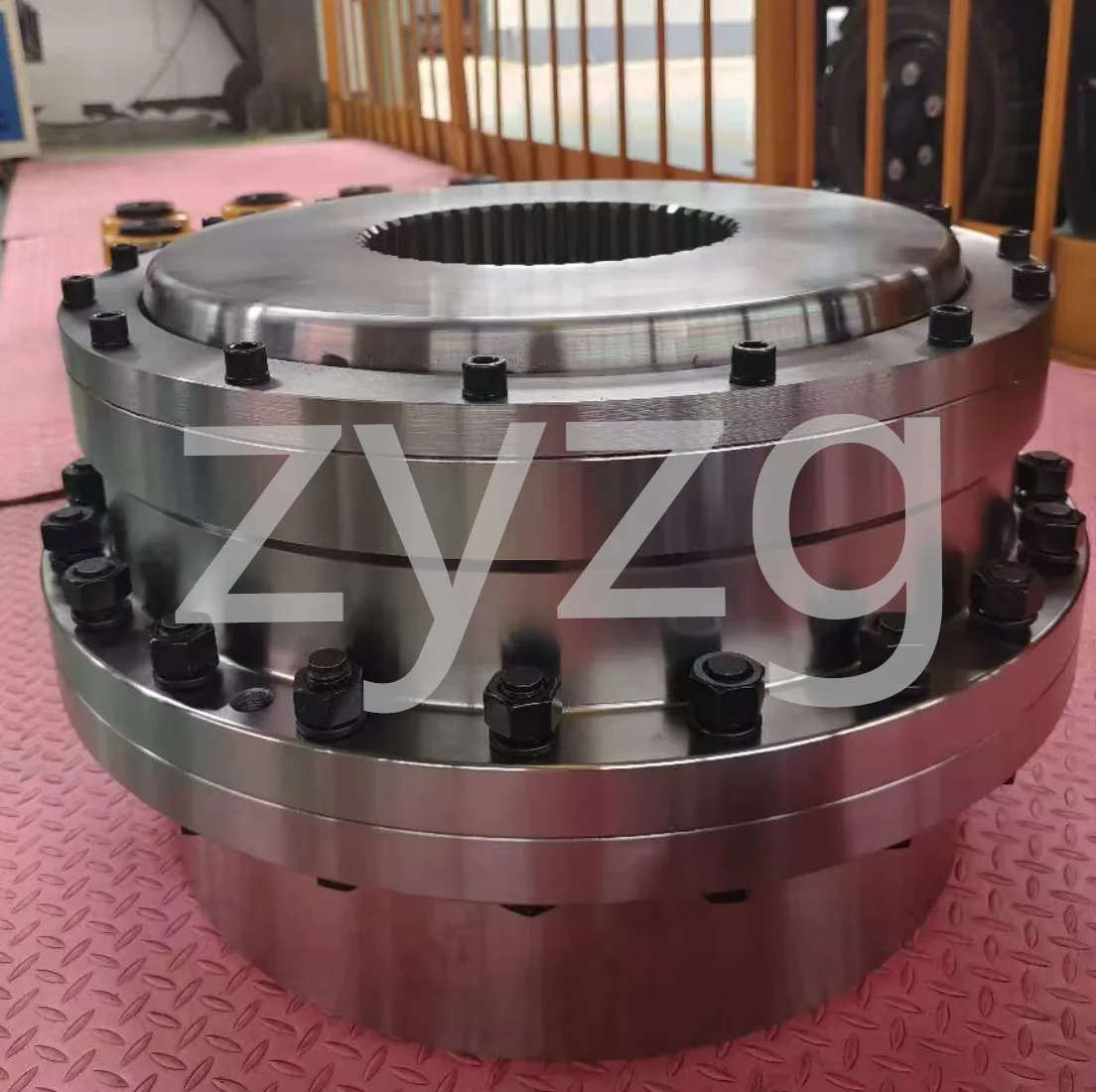

The power generation sector heavily relies on couplings for connecting turbines, generators, and other critical equipment. In thermal, hydroelectric, and wind power plants, couplings ensure the efficient transfer of rotational energy from the turbine to the generator. High-performance couplings are designed to handle high torque and speed, as well as thermal and mechanical stresses. For example, grid couplings are commonly used in power plants due to their ability to handle high torque loads and compensate for misalignments.

3. Oil and Gas Industry

The oil and gas industry operates in some of the harshest environments, requiring robust and reliable components. Couplings are essential in drilling rigs, pumps, compressors, and other critical equipment used in exploration, extraction, and refining processes. They help accommodate misalignments caused by the dynamic movements of drilling platforms and absorb the vibrations and shocks associated with drilling operations. Disc couplings, known for their high torque capacity and resistance to harsh environmental conditions, are frequently used in this industry.

4. Automotive Industry

In the automotive sector, couplings are used in various applications, including drive shafts, transmissions, and differentials. They ensure the efficient transfer of power from the engine to the wheels, accommodating misalignments caused by the vehicle’s movement and road conditions. Universal joints, a type of coupling, are widely used in the automotive industry for their ability to transmit power at varying angles, providing flexibility and reliability in the vehicle’s drivetrain.

5. Aerospace Industry

The aerospace industry demands high-precision and reliable components to ensure the safety and efficiency of aircraft. Couplings are used in aircraft engines, control systems, and other critical components. They help transmit power, accommodate misalignments, and reduce vibrations in highly dynamic and demanding environments. Flexible couplings, for example, are used in aircraft engines to ensure smooth power transmission and absorb operational shocks, contributing to the overall reliability and performance of the aircraft.

6. Marine Industry

In the marine sector, couplings are crucial for the operation of ships and offshore platforms. They are used in propulsion systems, auxiliary engines, and other onboard machinery. Marine environments are characterized by constant motion and varying loads, making the flexibility and reliability of couplings essential. Elastomeric couplings, known for their vibration-damping properties, are commonly used in marine applications to ensure smooth and efficient operation, even under challenging conditions.

7. Mining Industry

The mining industry relies on heavy-duty machinery for extraction, processing, and transportation of minerals. Couplings are used in conveyors, crushers, mills, and other mining equipment to ensure efficient power transmission and accommodate misalignments caused by the harsh and dynamic mining environment. Gear couplings, known for their high torque capacity and durability, are often used in mining applications to withstand the demanding conditions and ensure continuous operation.

Conclusion

Couplings are indispensable components in various industries, each with unique requirements and challenges. Their ability to transmit power, accommodate misalignments, absorb vibrations, and protect machinery from overloads makes them essential for ensuring the efficiency and reliability of industrial operations. As technology advances, the development of new coupling designs and materials continues to expand their applications, promising even greater performance and reliability in the future.

English

English