Coupling overload increases wear

Information summary: The coupling stiffness includes radial stiffness, axial stiffness and torsional stiffness. In actual engineering, load changes are caused by torque fluctuations causing torsional vibration, so the main stiffness affected by the coupling is the torsional stiffness. Generally, in shaft system transmission, the stiffness of other parts of the system will be much greater than the stiffness of the elastic coupling. The torsional stiffness of the coupling is used as the torsional stiffness of the transmission shaft system.

The stiffness of the coupling includes radial stiffness, axial stiffness and torsional stiffness. In actual engineering, load changes are caused by torque fluctuations causing torsional vibration, so the main stiffness affected by the coupling is the torsional stiffness. Generally, in shaft system transmission, the stiffness of other parts of the system will be much greater than the stiffness of the elastic coupling. The torsional stiffness of the coupling is used as the torsional stiffness of the transmission shaft system.

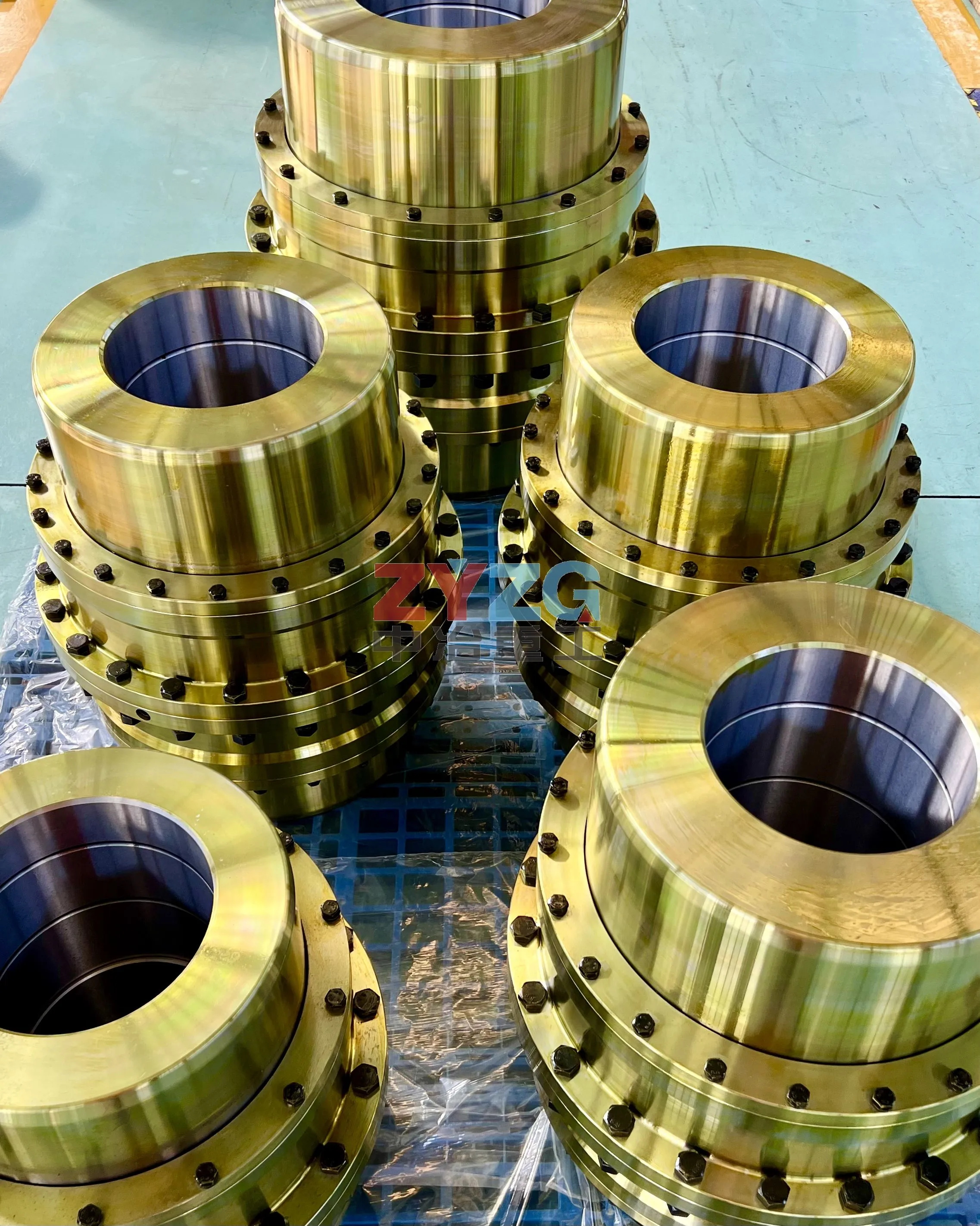

When installing bolts, be sure to pay attention to the direction of the bolts. Do not install the bolts in any direction, otherwise it will cause distortion. Long-term operation will cause damage to the surface of the bolt mating section and the small hole of the axle joint. Because the surface of the mating section between the bolt and the flange is a very important mating section for transmitting torque, the integrity of the surface directly affects the performance, so that the bolt assembly can perform well.

In high-speed and heavy-load power transmission, some couplings also play the role of buffering, damping vibration and improving the dynamic performance of the shaft system. The coupling consists of two halves, connected to the driving shaft and the driven shaft respectively. Therefore, sometimes during the installation of couplings, we must also pay attention to the deviations that occur during the connection between shafts. They have beautiful surfaces and corrosion resistance, and do not undergo surface treatments such as color plating.

In general, most power machines are connected to the working machine by means of a coupling. Aluminum alloy can be used when the load is sensitive. Before installation, check whether the two axes of the prime mover and the working machine are concentric, and whether there are wrapping paper and bruises on the surfaces of the two axes. When the coupling is started and stopped by the transmission equipment for a long time or is slightly overloaded, the durability of the coupling accessories and the two coupling halves is felt.

English

English