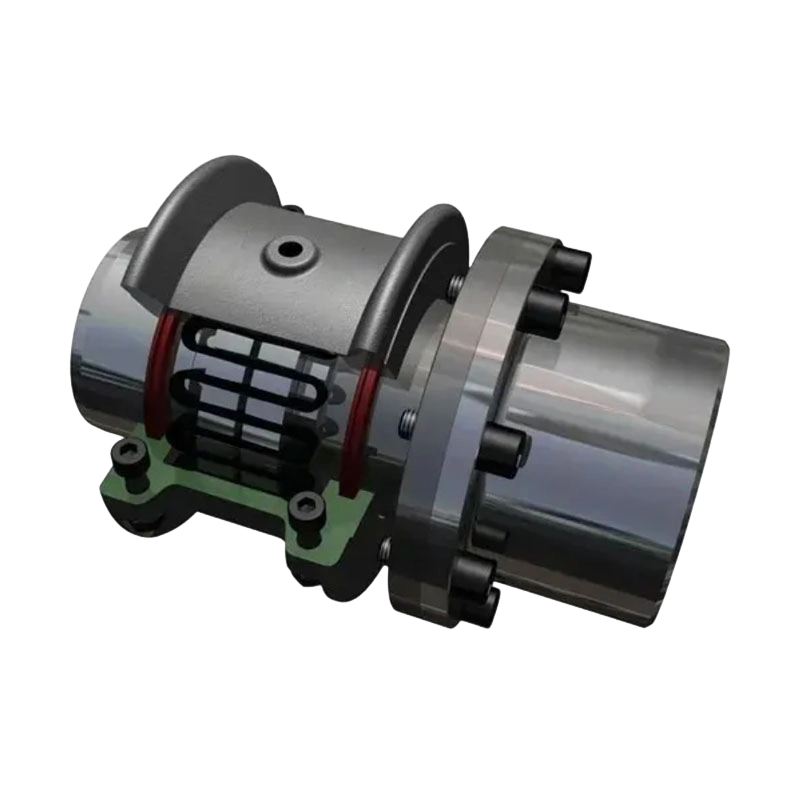

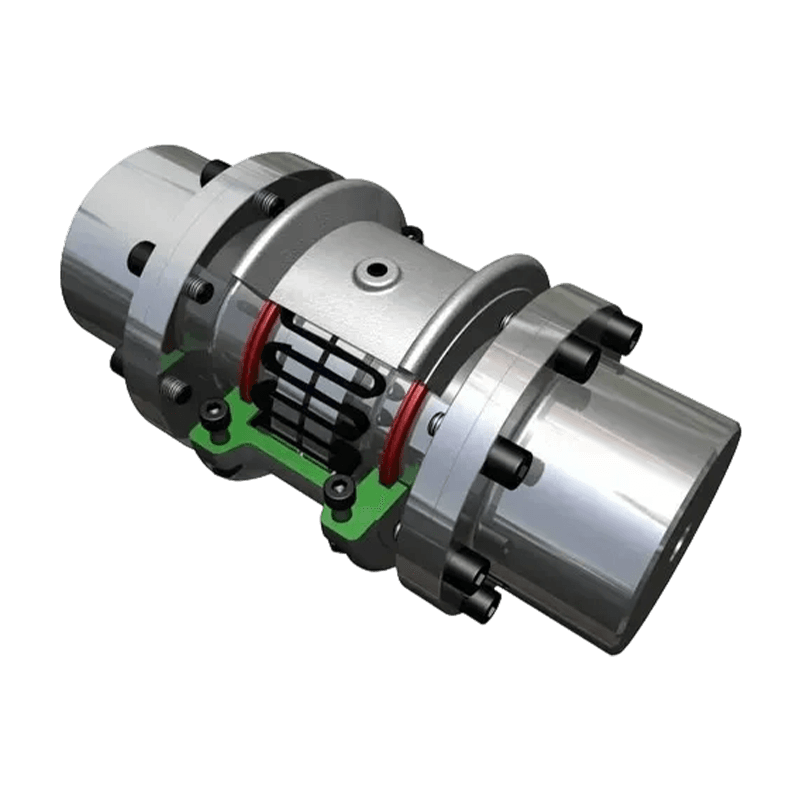

Overview The T35 Single Flange Type Snake Spring Coupling is a versatile and robust flexib...

Don't hesitate to send a message

+86 511 8572 3900

+86 15106109009 Keep in touch

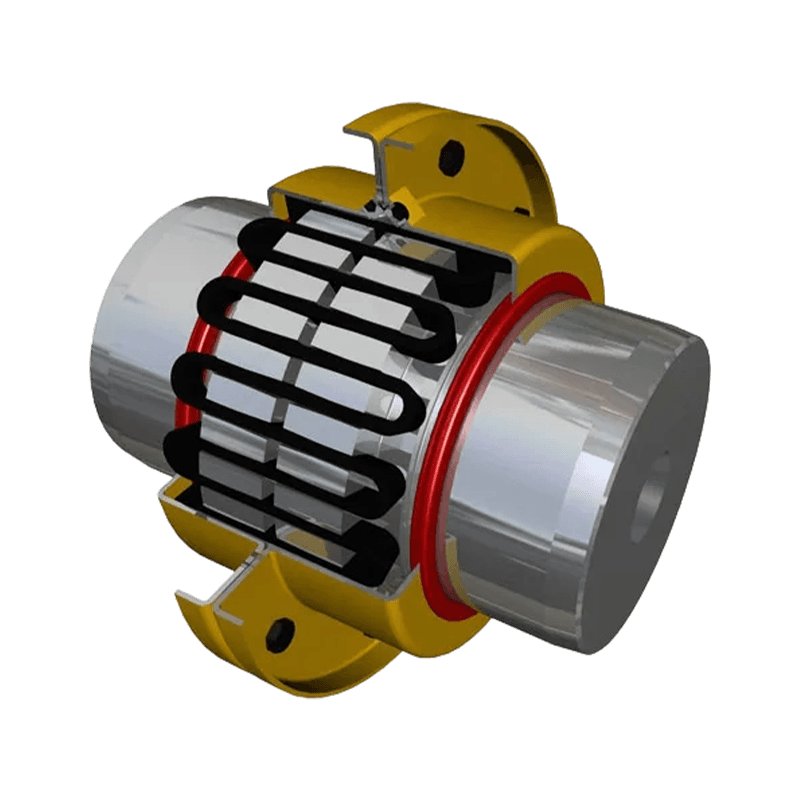

Flexible Couplings with Metal Elastic Elements

The main features of the flexible couplings with metal elastic element are as follows:

High Temperature Resistance

The use of metal elastic components, such as diaphragms and grid springs, allows stable operation under elevated temperatures and high rotational speeds, without concerns related to aging or material degradation.

High Strength

The metal elastic element flexible couplings are designed to transmit high torque while maintaining accurate motion control, offering reliable performance over long service periods without hysteresis or creep.

Zero Gaps

Without elastic delay, metal elastic couplings ensure consistent transmission ratios and are commonly selected for servo and precision drive systems.

Weak Buffering

Compared to non-metallic elastic couplings, its buffering and vibration reduction capabilities are weaker, and higher installation accuracy is required.

Our diaphragm couplings and grid couplings are manufactured with high precision and are designed to deliver stable and reliable performance across a wide range of industrial applications.

-

-

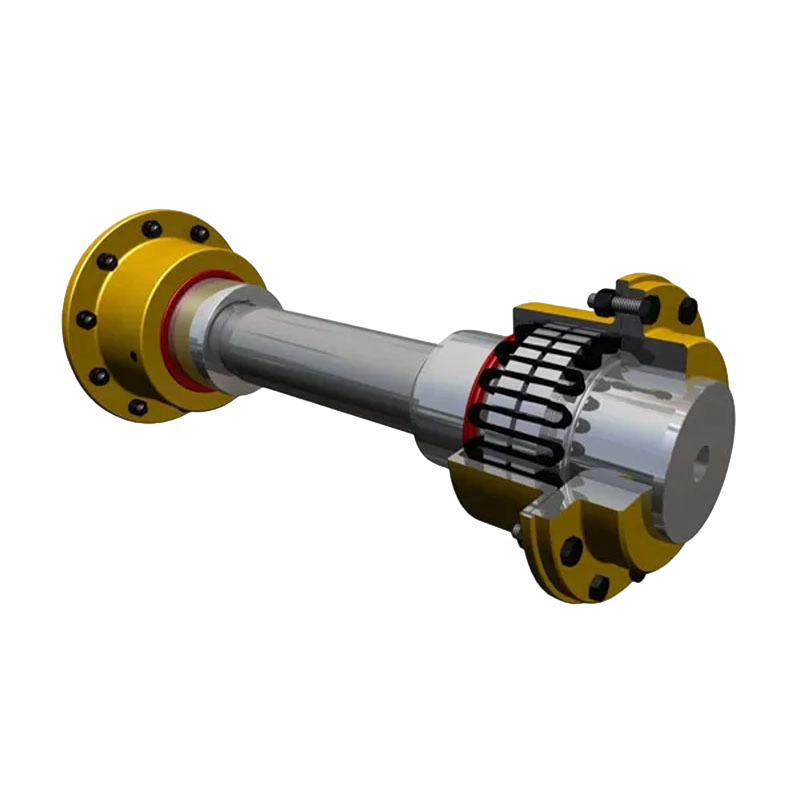

T50 snake spring coupling with connect shaft

T50 snake spring coupling with connect shaftA snake spring coupling with a connecting shaft is a mechanical device used in power trans...

-

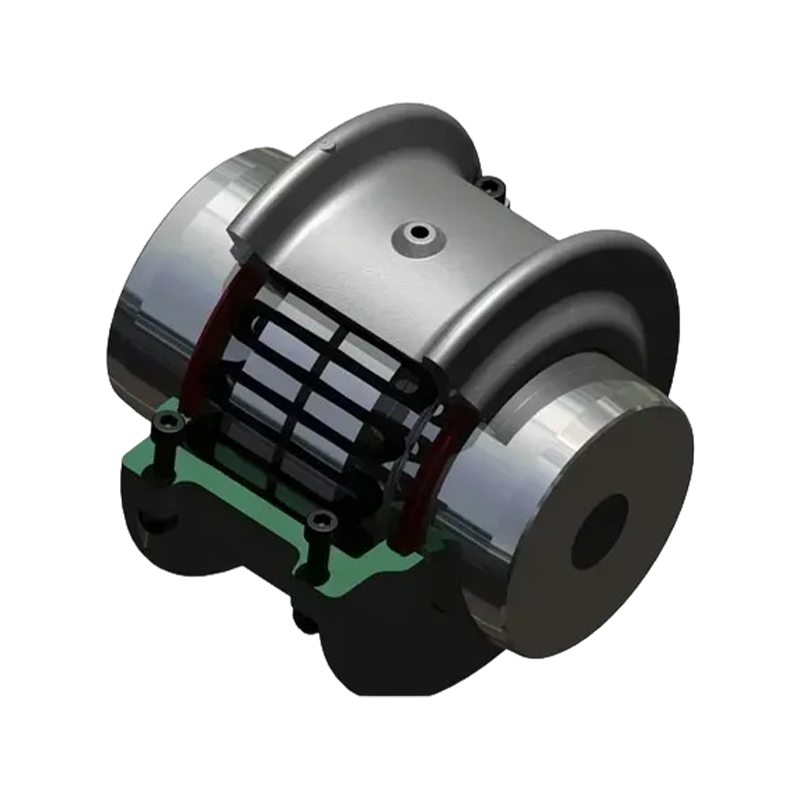

T10 snake spring coupling

T10 snake spring couplingThe T10 Snake Spring Coupling represents an innovative engineering solution designed for v...

-

T20 high speed snake spring coupling

T20 high speed snake spring couplingA T20 high-speed snake spring coupling is a type of flexible coupling used in mechanical s...

-

T31 snake spring coupling with double flange

T31 snake spring coupling with double flangeOverview The T31 Snake Spring Coupling with Double Flange is a high-performance flexible c...

Zhongye Heavy Industry Technology (Zhenjiang) Co., Ltd. is located in a well-known ancient city, Zhenjiang. We are an enterprise integrating R & D, manufacturing, and sales. Our products are widely used in metallurgical equipment, mining equipment, water equipment, lifting equipment, paper equipment, port equipment and other industries.

Our main products are toothed coupling, elastic sleeve column pin coupling, elastic column pin coupling, gear coupling with elastic pin, a universal coupling, tire coupling, jaw coupling, star coupling, diaphragm coupling, drum coupling and grid coupling, the Oldham coupling, flange coupling, clip shell coupling, GL type roller chain coupling and a safety coupling, and so on. Our company also undertakes a variety of non - standard coupling designs and manufacturing.

New workshop covers an area of about 16463.52 m². heavy workshop 5,500 M2, Precision workshop 4,600 m² , office building and the gymnasium 2000 M2, Dinning hall 500m² , Warehouse 1000 m², Roads, greening, parking areas 3563 M2.

-

2025.11.14Universal Joint Shield: Function, Specification and ApplicationUniversal Joint Housing: Function, Specification and Application Report 1. Overview The universal joint housing, also known as a universal joint shield or boot, is a critical protective component installed externally on universal joints. It is widely used in automotive, industrial machinery, and engineering equipment fields, designed to safeguard the universal joint assembly and ensure stable power transmission. Its structural design and material selection are tailored to different operating environments, ranging from flexible dust-proof boots for passenger cars to rigid protective casings for heavy industrial equipment. 2. Core Functions - Contaminant Isolation: Effectively blocks dust, moisture, sand, and other external impurities from entering the internal structure of the universal joint, preventing abrasive wear and corrosion of key components such as universal joints, bearings, and shafts. - Lubrication Preservation: Maintains the sealing of the internal lubrication system, preventing leakage of lubricating oil and ensuring sufficient lubrication of moving parts, thus optimizing transmission efficiency and reducing energy loss. - Safety Protection: Eliminates potential hazards caused by exposed rotating components, avoiding accidental contact injuries; meanwhile, it absorbs external impacts and vibrations to reduce damage to the universal joint. - Service Life Extension: By reducing component wear, corrosion, and mechanical damage, the overall service life of the universal joint assembly is significantly prolonged, lowering maintenance costs and downtime. 3. Key Specifications 3.1 Material Options - Rubber: Chloroprene rubber (CR) is commonly used for its excellent flexibility, low-temperature resistance, and weatherability, suitable for automotive universal joint boots. - Plastic: Lightweight and cost-effective, applicable to mid-to-low-end equipment; reinforced plastic variants offer enhanced impact resistance. - Metal: High-strength steel or aluminum alloys, featuring superior durability and load-bearing capacity, used in heavy industrial equipment such as steel rolling machinery. - Composite Materials: Combine the advantages of metal and plastic, providing balanced strength, flexibility, and corrosion resistance, with broad application prospects in high-performance equipment. 3.2 Structural Types (Based on JB/T 9791—2022 Standard) - Corrugated three-clamp type - Corrugated two-clamp type - Straight-tube three-clamp type - Corrugated buckle type - Double C-shaped plastic clip fixed type - Straight-tube screw fixed type 3.3 Performance Requirements - Mechanical Strength: No cracks or fractures after room-temperature axial and radial loading tests. - Low-Temperature Stability: Maintains structural integrity and performance during low-temperature axial loading and impact tests. - Weather Resistance: For plastic or rubber materials, no obvious discoloration, cracking, or degradation after 1000 hours of weathering tests. - Sealing Performance: Effectively prevents lubricant leakage and contaminant intrusion under long-term operation. 3.4 Connection Methods - Clamp connection (for corrugated three-clamp and two-clamp types) - Screw connection (for straight-tube screw fixed types) - Plug-in connection (for dust-proof universal joint housings) 4. Application Scenarios - Automotive Industry: Passenger cars and commercial vehicles use flexible universal joint boots (typically rubber or plastic) to protect drive shaft universal joints, adapting to vehicle vibration and angle changes. - Industrial Machinery: Steel rolling mills, mining equipment, and conveyor systems adopt rigid metal or composite housings to withstand harsh working conditions such as high load, dust, and impact. - Engineering Equipment: Excavators, loaders, and other construction machinery use high-strength, wear-resistant housings to ensure reliable operation in complex outdoor environments.

-

2025.11.08The precautions for using a universal shaftThe following are the precautions for using a universal shaft: Installation Ensure correct alignment: The axes of the connected shafts should be within the allowable angular deviation range specified by the manufacturer to avoid excessive stress and wear. - Tighten the mounting bolts/nuts firmly to prevent loosening during operation. Operation - Do not exceed the rated speed and torque of the universal shaft to avoid damage or failure. - Keep the operating temperature within the recommended range; high temperature may affect the material properties and lubrication performance. Monitor vibration and noise regularly. Abnormal vibration or noise may indicate misalignment, wear, or other problems. Maintenance - Regularly check the lubrication condition and replenish or replace the lubricant as required to reduce friction and wear. - Inspect the universal shaft for wear, cracks, or deformation at regular intervals. Replace worn or damaged parts in a timely manner. - After long-term storage or disuse, check and test the universal shaft before reuse to ensure its performance. These precautions should be strictly observed to ensure the safe, reliable, and efficient operation of the universal shaft.

-

2025.10.24Nitriding treatment of couplingNitriding treatment of coupling :The high-strength drum-shaped gear coupling is made by integrating factors such as the selection of coupling material, the subsequent heat treatment process, and precise manufacturing. Nitriding treatment is used to enhance the surface strength of the gear coupling. Precision manufacturing of drum-shaped gear coupling: First, attention should be paid to the selection of coupling material. For example, for heavy-load GICL drum-shaped gear couplings, the material should be selected based on the usage conditions of the user's equipment, whether it is 45# forged steel or 42CRMO forged steel? Even for large-sized gear couplings above GICL23 (outer diameter is 1010), cast steel form can be selected, but the brand of cast steel material and the defects (gas holes, sand holes, etc.) of cast steel must be strictly controlled. After determining the material of the drum-shaped gear coupling, the corresponding heat treatment should be followed to fully exert the inherent strength performance of the coupling material. The heat treatment of drum-shaped gear coupling is not just surface quenching, because surface quenching only increases the hardness of the tooth surface, while the strength and fatigue strength of the main body of the gear coupling and its service life are the key factors. Nitriding treatment can increase the surface hardness of the entire gear coupling, and the hardness is much greater than that of high-frequency surface treatment. However, to achieve the comprehensive effect of a high-strength coupling, corresponding quenching and tempering pre-treatment should be followed before the nitriding treatment, so as to comprehensively improve the strength of the coupling body and the surface strength.

-

2025.10.23The features and applications of gear coupling with a brake discThis is a coupling with a brake disc, a type of coupling, with the following features and applications: Features - Structural Design: Integrates the functions of a coupling and a brake disc. It has a compact structure and can realize braking operation while transmitting torque. - Transmission Performance: It can effectively transmit large torque and meet the power transmission requirements under different working conditions. - Braking Function: The equipped brake disc can cooperate with the braking device to achieve accurate and reliable braking, ensuring the safety of equipment operation. - Adaptability: For the transmission system with braking requirements, there is no need to install an additional brake disc, which saves space and simplifies the equipment layout. Applications It is mainly used in mechanical equipment fields that require both power transmission and braking control, such as: - Equipment in mining machinery, such as conveyors and hoists, can realize quick start-stop and safe braking of the equipment through the brake disc while transmitting power. - Lifting equipment, such as the transmission system of cranes, uses its braking function to ensure the safety and reliability of lifting operations. - Some large industrial fans, water pumps and other equipment, when emergency shutdown or precise speed control is required, the braking function of this coupling can play an important role.

-

2025.10.17The flange coupling featureThe flange coupling is used in metallurgical equipment and mining equipment. It is a rigid coupling and does not have the ability to compensate for radial, axial and angular deviations. During installation, it is required that the coaxiality of the two shafts be extremely good.

-

2025.10.10What is the main purpose of the roller chain coupling?The roller chain coupling has the advantages of simple structure (consisting of four components), convenient assembly and disassembly, no need to move the two connected shafts during disassembly, compact size, light weight, definite compensation capability, low requirements for installation accuracy, stable operation, long service life and low cost. The roller chain coupling should operate under good lubrication and with a protective cover. The roller chain coupling is an ideal product for solving the difficult corrosion problems caused by high-temperature dilute sulfuric acid, hydrofluoric acid, hydrochloric acid and various other acids (mainly based on actual reports) as well as other corrosive substances. It is resistant to positive and negative forces, vacuum, alternating temperature changes, and the lining layer remains unaffected. It can solve the delamination problem of equipment with polytetrafluoroethylene inner lining. The suitable processing accuracy is an inherent characteristic of this process. Apart from the tolerance range, the size of the part and the batch quantity are also taken into consideration. When processing a large number of parts, a tolerance of 5 μm is maintained; when processing two cooperating parts, a tolerance of 2 μm is maintained, or small-diameter face mills are used for processing on a machine with a positioning accuracy of 0.3 μm, etc. All of these belong to the category of high-precision processing. That is to say, the size of the part and the batch quantity of the workpiece determine the difficulty of achieving certain specific tolerances.

- Quick Links

- About

- Products

- Our Service

- News & Events

- Contact

- Products Series

- Flexible Couplings with Non-Elastic Elements

- Flexible Couplings with Metal Elastic Elements

- Flexible Couplings with Non-Metallic Elastic Elements

- Safety Coupling

- Rigid Coupling

- Contact Us

- Tel : +86 511 8572 3800 +86 511 8572 3900

- Mobile : +86 15106109009

- Email : [email protected]

- Add:No.1 Zhongye Yingbin Avenue, Gaozi Street, Dantu Economic Development Zone, Zhenjiang City, Jiangsu Province, China.

English

English