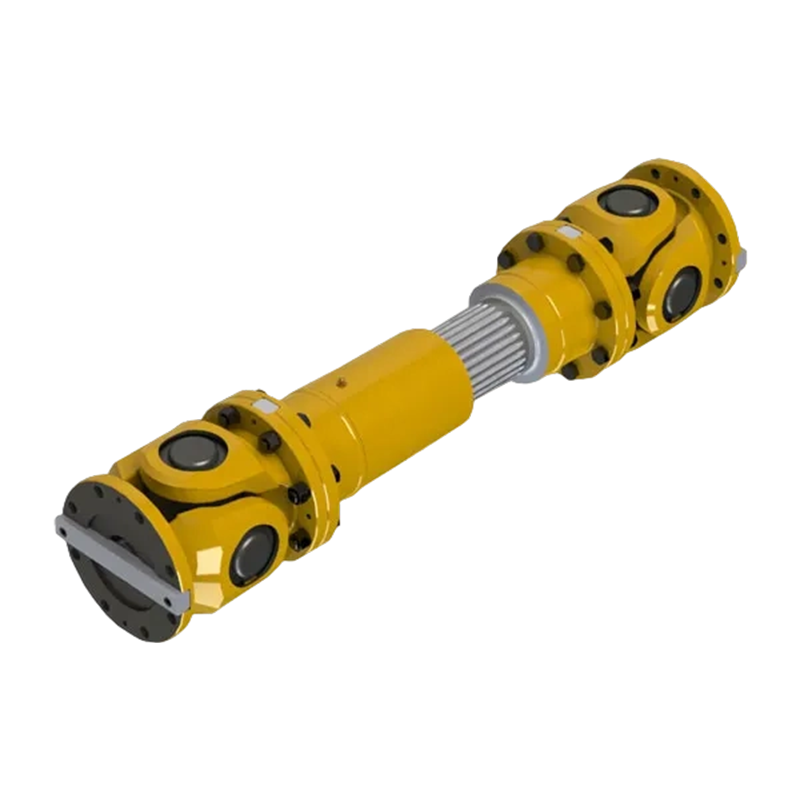

The SWC-DH Type Short Expansion Welding Universal Coupling is a cutting-edge solution desi...

Products

Products

Don't hesitate to send a message

+86 511 8572 3900

+86 15106109009 Keep in touch

Products

Our main products are toothed coupling, elastic sleeve column pin coupling, elastic column pin coupling, gear coupling with elastic pin, a universal coupling, tire coupling, jaw coupling, star coupling, diaphragm coupling, drum coupling and grid coupling, the Oldham coupling, flange coupling, clip shell coupling, GL type roller chain coupling and a safety coupling, and so on.

-

-

SWC-BF large size standard expansion flange universal coupling

SWC-BF large size standard expansion flange universal couplingThe SWC-BF Large Size Standard Expansion Flange Universal Coupling represents a pinnacle i...

-

SWC-BF standard expansion flange type universal coupling

SWC-BF standard expansion flange type universal couplingThe SWC Standard Telescopic Flange Type Universal Joint Coupling is an advanced engineerin...

-

SWC-BH standard expansion welded universal coupling

SWC-BH standard expansion welded universal couplingThe SWC Standard Telescopic Welded Universal Joint Coupling is a versatile and reliable so...

-

SWC-WF type flange universal coupling without expansion welding

SWC-WF type flange universal coupling without expansion weldingIntroduction: The SWC-WF Type Flange Universal Coupling without Expansion Welding is a pre...

-

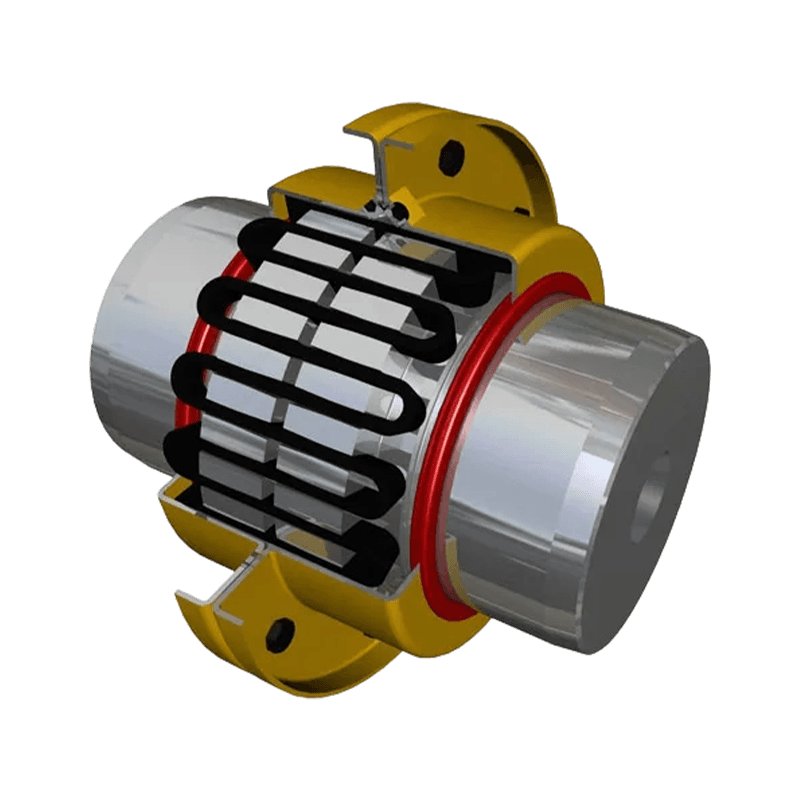

T10 snake spring coupling

T10 snake spring couplingThe T10 Snake Spring Coupling represents an innovative engineering solution designed for v...

-

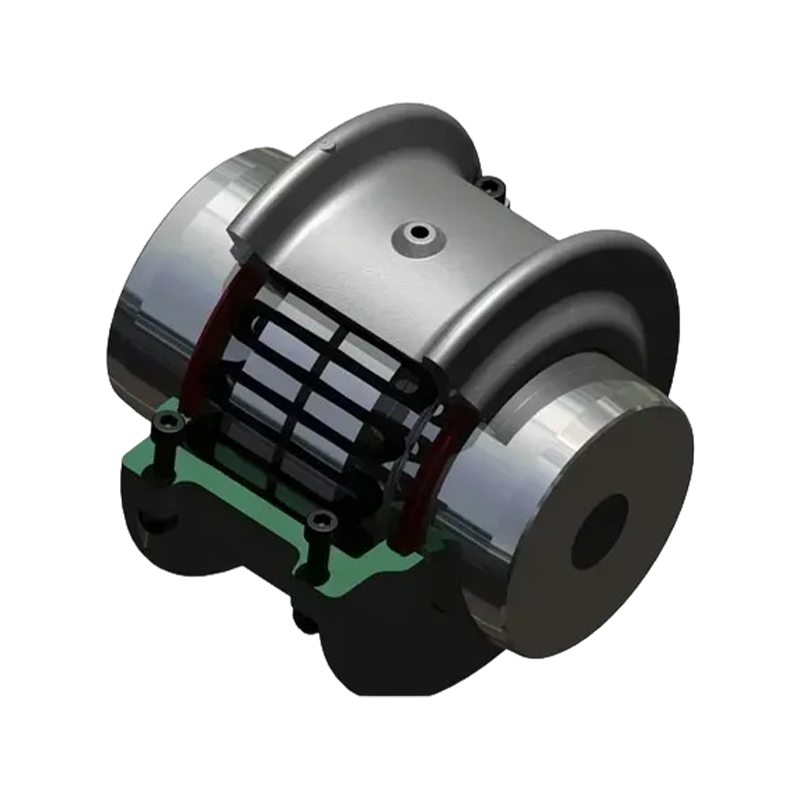

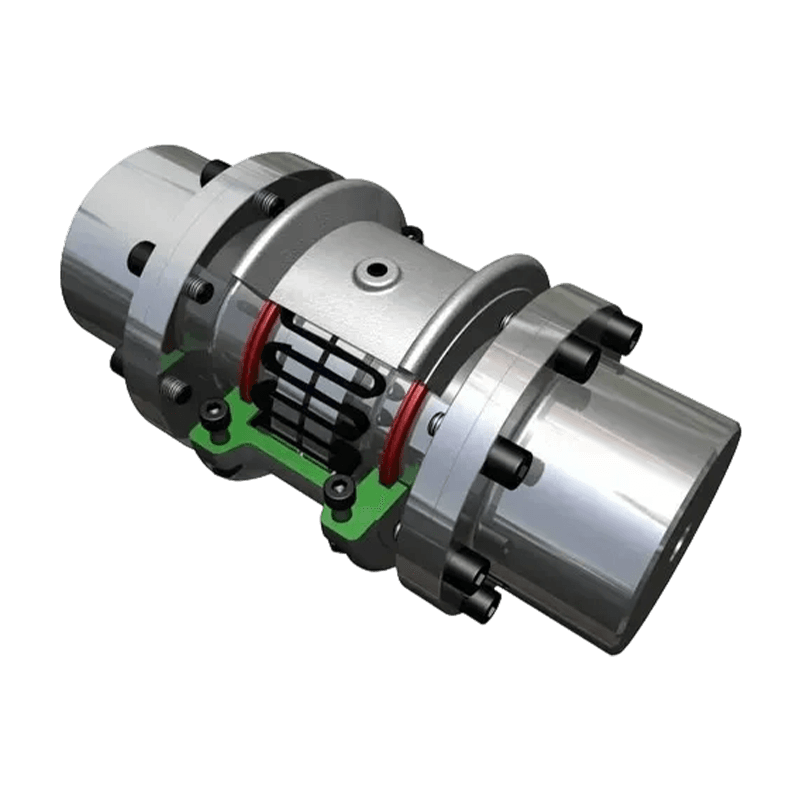

T20 high speed snake spring coupling

T20 high speed snake spring couplingA T20 high-speed snake spring coupling is a type of flexible coupling used in mechanical s...

-

T31 snake spring coupling with double flange

T31 snake spring coupling with double flangeOverview The T31 Snake Spring Coupling with Double Flange is a high-performance flexible c...

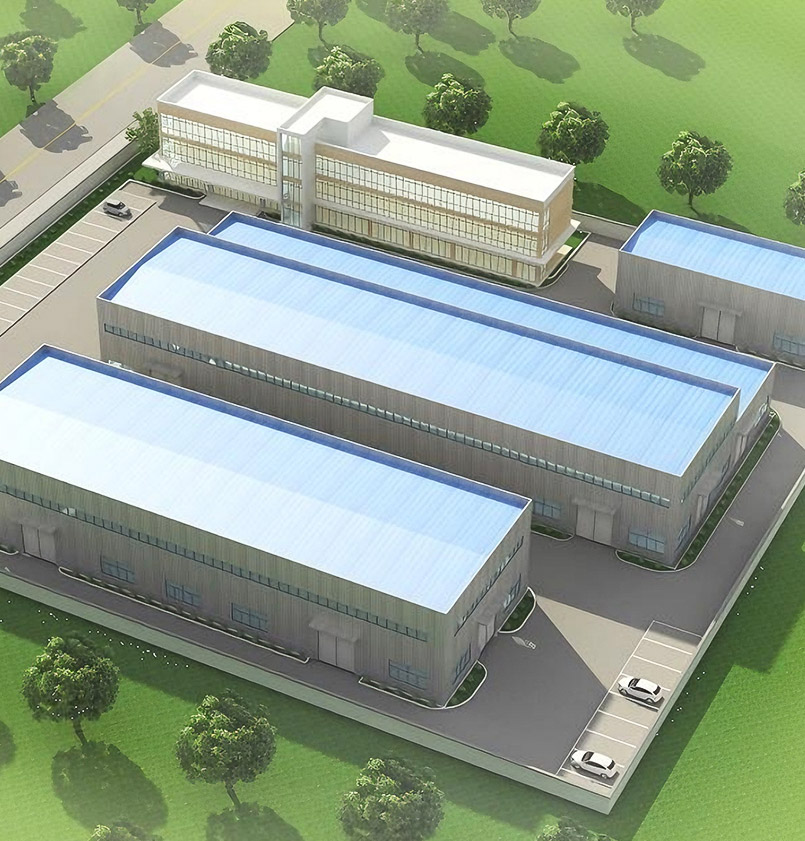

Zhongye Heavy Industry Technology (Zhenjiang) Co., Ltd. is located in a well-known ancient city, Zhenjiang. We are an enterprise integrating R & D, manufacturing, and sales. Our products are widely used in metallurgical equipment, mining equipment, water equipment, lifting equipment, paper equipment, port equipment and other industries.

Our main products are toothed coupling, elastic sleeve column pin coupling, elastic column pin coupling, gear coupling with elastic pin, a universal coupling, tire coupling, jaw coupling, star coupling, diaphragm coupling, drum coupling and grid coupling, the Oldham coupling, flange coupling, clip shell coupling, GL type roller chain coupling and a safety coupling, and so on. Our company also undertakes a variety of non - standard coupling designs and manufacturing.

New workshop covers an area of about 16463.52 m². heavy workshop 5,500 M2, Precision workshop 4,600 m² , office building and the gymnasium 2000 M2, Dinning hall 500m² , Warehouse 1000 m², Roads, greening, parking areas 3563 M2.

-

2025.04.18Zhongye Heavy Industry Technology’s Flexible Couplings with Metal Elastic Elements Power Industrial Efficiency Across Global SectorsZhenjiang, China – As industries increasingly prioritize precision, durability, and sustainability in mechanical systems, Zhongye Heavy Industry Technology (Zhenjiang) Co., Ltd. continues to showcase its expertise in manufacturing high-performance Flexible Couplings with Metal Elastic Elements—a proven solution for critical power transmission challenges. Engineered for Extreme Conditions Zhongye’s couplings leverage advanced metal elastic elements to deliver unmatched torsional flexibility and resilience. Designed to operate in harsh environments—from offshore wind farms to high-temperature mining operations—these couplings excel where traditional elastomeric or grid-type alternatives fail. Key benefits include: - Zero Backlash: Ensures precision in robotics, CNC machinery, and aerospace applications. - Corrosion & Heat Resistance: Withstands temperatures up to 300°C and aggressive chemical exposure. - Vibration Damping: Reduces equipment wear by 30-40%, extending machinery lifespan. Driving Industrial Advancements The couplings are integral to modernizing Industry 4.0 infrastructure. By enabling seamless power transmission in high-speed automation and heavy-load scenarios, they support energy-efficient manufacturing and reduce operational downtime. A recent case study in the cement industry demonstrated a 20% increase in conveyor system uptime after adopting Zhongye’s solution. Global Reach, Local Expertise Zhongye Heavy Industry Technology serves clients in 50+ countries, offering customizable couplings for shaft diameters ranging from 25mm to 500mm. The company’s R&D team collaborates closely with clients in sectors like marine propulsion, steel production, and automated logistics to refine performance metrics.

-

2025.03.28Couplings in Lifting Machinery: Enhancing Efficiency and SafetyIn the field of lifting machinery, couplings play a crucial role in ensuring efficient power transmission, enhancing operational safety, and reducing maintenance costs. These mechanical components connect two rotating shafts, enabling smooth torque transfer while accommodating misalignments and dampening vibrations. The Role of Couplings in Lifting Machinery Lifting machines, such as cranes, hoists, and elevators, require precise and reliable motion control. Couplings help in: Power Transmission: They ensure seamless energy transfer from motors to gears and pulleys, improving efficiency. Misalignment Compensation: Flexible couplings accommodate slight shaft misalignments, preventing undue stress on the system. Vibration Reduction: By absorbing shocks and vibrations, couplings enhance the longevity of machine components and provide a smoother operation. Overload Protection: Some couplings feature torque-limiting functions, preventing damage from sudden load changes. Types of Couplings Used in Lifting Machinery Different types of couplings are utilized based on the specific requirements of lifting applications: Flexible Couplings: Used to compensate for shaft misalignments and reduce vibration. Rigid Couplings: Ideal for applications where precise shaft alignment is maintained. Gear Couplings: Suitable for heavy-duty lifting equipment requiring high torque transmission. Hydraulic Couplings: Used in dynamic load applications to provide smooth torque transfer and shock absorption. Advancements in Coupling Technology With the advancement of materials and engineering, modern couplings are designed for greater durability and efficiency. High-performance materials such as carbon fiber and reinforced polymers are being integrated into coupling designs, reducing weight while maintaining strength. Additionally, smart couplings equipped with sensors for real-time monitoring are enhancing predictive maintenance capabilities. Conclusion As the demand for high-performance lifting machinery grows, the role of couplings in ensuring efficiency and safety becomes increasingly significant. Selecting the right type of coupling for specific applications can lead to improved operational reliability, reduced maintenance downtime, and enhanced overall performance. With continuous innovation, couplings will continue to be an essential component in modern lifting machinery, contributing to the advancement of industrial automation and heavy equipment operations.

-

2025.03.21Snake Spring Couplings for Efficient Power TransferIn modern industrial transmission systems, efficient and stable couplings are crucial for ensuring smooth operation. Snake Spring Couplings stand out with their excellent shock absorption, outstanding impact resistance, and high torque transmission capability, making them widely used in various mechanical applications. Shock Absorption to Extend Equipment Lifespan Snake Spring Couplings utilize high-strength snake-shaped springs as the core component. These springs effectively absorb impact loads and vibrations through elastic deformation, reducing torsional oscillations and minimizing equipment wear. This significantly extends the lifespan of machinery. High Torque Transmission for Efficient Operation Designed for high torque transmission, Snake Spring Couplings are well-suited for heavy-duty applications. Unlike traditional rigid couplings, the flexible spring structure allows stable operation under high loads, ensuring continuous and efficient power transmission. Axial Compensation for Complex Working Conditions With the ability to compensate for angular, axial, and radial misalignments, Snake Spring Couplings adapt to installation errors and thermal expansion/contraction during operation. This flexibility makes them ideal for precision machinery, pumps, compressors, and other demanding applications. Wide Applications to Boost Industrial Efficiency Thanks to their superior mechanical properties, Snake Spring Couplings are widely used in mining machinery, metallurgical equipment, power generation, petrochemical industries, and marine transmission systems, providing reliable and efficient power transmission solutions.As industrial automation and smart manufacturing continue to advance, selecting high-performance couplings is more important than ever. Snake Spring Couplings not only enhance equipment stability but also help reduce maintenance costs, making them an ideal choice for modern transmission systems.

-

2025.03.14Precise Coupling Concentricity Detection to Enhance Equipment EfficiencyIn modern industrial production, equipment stability and operational efficiency are crucial. Coupling concentricity detection plays a key role in ensuring mechanical system performance, longevity, and maintenance cost control. Impact of Concentricity DeviationSince couplings connect two shafts and transmit power, any deviation in concentricity can cause several issues:Increased equipment vibration, affecting operational stabilityHigher noise levels, impacting the working environmentAccelerated wear of bearings and related components, shortening equipment lifespanHigher energy consumption, leading to increased production costs Efficient Detection MethodsCommon methods for coupling concentricity detection include:Dial Indicator Measurement – Measures radial and axial runout to determine concentricity deviationsLaser Alignment Systems – Uses high-precision laser technology for fast and accurate detection and alignmentStraightedge and Feeler Gauge Inspection – A simple and quick method for preliminary assessment Industry Trends and DevelopmentsWith the rise of industrial automation, more companies are adopting automated alignment systems to improve detection accuracy and efficiency. Precise concentricity detection not only reduces equipment failures but also optimizes production processes and enhances overall operational effectiveness. Accurate coupling concentricity detection has become an essential part of modern industrial equipment maintenance. Companies that prioritize efficient detection will significantly improve productivity, reduce maintenance costs, and maintain a competitive edge in the market. Ensure Equipment Health – Start with Precise Coupling Concentricity Detection!

-

2025.03.07TC-Type Elastic Sleeve Pin Coupling: A Reliable Solution for Power TransmissionIn industrial power transmission, selecting the right coupling is essential to ensure smooth operation, durability, and efficiency. The TC-Type Elastic Sleeve Pin Coupling is designed for medium and small power shaft transmission systems, offering shock absorption, buffering, and compensation for minor misalignments. Key Features & Benefits: Reliable Connection – Links two coaxial shafts for stable power transmission. Shock & Vibration Absorption – Enhances equipment lifespan and operational stability. Flexible Misalignment Compensation – Reduces stress on connected components. Durable & Cost-Effective – Built for long-term use with minimal maintenance. Wide Range of Applications: Pumps, fans, compressors – Ensuring smooth operation in fluid machinery. Reducers, motors – Enhancing efficiency in power transmission systems. Conveyors, lifting & mining machinery – Providing stability in material handling. Metallurgical, chemical & paper industries – Supporting industrial processes. This coupling is ideal for low to medium-speed and moderate torque applications, making it a preferred choice for industries requiring stable and cost-efficient solutions. However, for high-precision, ultra-high-speed, or heavy-torque systems, alternative coupling types may be more suitable. With its proven performance and durability, the TC-Type Elastic Sleeve Pin Coupling remains a trusted choice for various industrial applications. For more information on how this coupling can improve your system, contact us today!

-

2025.02.28T31 Snake Spring Coupling with Double Flange: Enhancing Efficiency Across IndustriesIn an effort to drive innovation and efficiency across multiple sectors, the T31 Snake Spring Coupling with Double Flange has been introduced as a game-changer for industries such as manufacturing, power generation, oil & gas, mining, and marine. Key Features and ApplicationsThe T31 coupling is designed to offer superior power transmission with minimal vibration and noise. Its durable and long-lasting construction ensures that it can withstand the rigorous demands of high-stress environments, from manufacturing plants to offshore oil rigs. The coupling is highly versatile, making it an ideal choice for a wide range of applications. Advantages of T31 Coupling · Smooth Power Transmission: Reduces vibration and noise, leading to improved system performance. · Durability and Longevity: Built to perform reliably in tough industrial settings. · Cost Efficiency: The design lowers maintenance and operational costs, making it a cost-effective solution for long-term use. Whether it's enhancing the performance of machinery in the power generation sector or ensuring the reliability of operations in oil and gas extraction, the T31 Snake Spring Coupling stands out as a reliable, low-maintenance solution for industries worldwide. ConclusionThe T31 Snake Spring Coupling with Double Flange represents a significant advancement in industrial coupling technology, offering unmatched performance and cost savings across key sectors. By providing a seamless integration of power transmission, industries can operate more efficiently and with greater reliability. For more information about the T31 Snake Spring Coupling, contact us today!

- Quick Links

- About

- Products

- Our Service

- News & Events

- Contact

- Products Series

- Flexible Couplings with Non-Elastic Elements

- Flexible Couplings with Metal Elastic Elements

- Flexible Couplings with Non-Metallic Elastic Elements

- Safety Coupling

- Rigid Coupling

- Contact Us

- Tel : +86 511 8572 3800 +86 511 8572 3900

- Mobile : +86 15106109009

- Email : [email protected]

- Add:No.1 Zhongye Yingbin Avenue, Gaozi Street, Dantu Economic Development Zone, Zhenjiang City, Jiangsu Province, China.

English

English